Precision Parts Machining and Customization: Your Partner in Innovation

In the realm of precision parts machining and customization, finding a reliable partner is crucial for success. GreatLight CNC Machining Factory, established in 2011, has positioned itself as a leader in this field, offering advanced five-axis CNC machining services tailored to meet the unique needs of various industries.

Our Mission and Capabilities

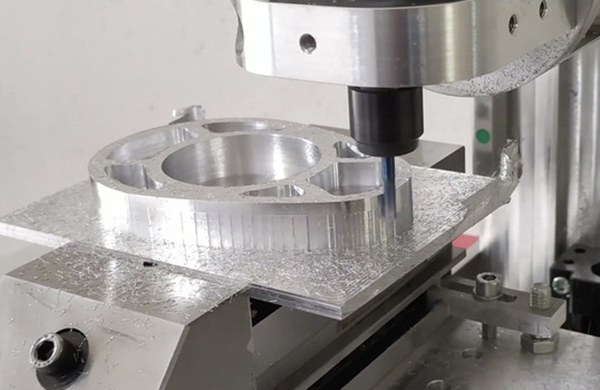

GreatLight CNC Machining Factory is committed to providing top-tier precision machining services, leveraging our extensive experience and state-of-the-art equipment. Our facility, located in Chang’an District, Dongguan City, is equipped with 127 pieces of precision machinery, including high-precision five-axis, four-axis, and three-axis CNC machining centers. This extensive toolkit allows us to handle complex geometries and deliver parts with unparalleled precision, achieving tolerances as tight as ±0.001mm.

Why Choose GreatLight?

Advanced Technology and Equipment

Our investment in cutting-edge machinery ensures that we can handle even the most complex machining tasks efficiently. From five-axis CNC machining centers to advanced 3D printing technologies, our equipment is designed to meet the highest standards of precision and quality.

Comprehensive Quality Management

GreatLight CNC Machining Factory is ISO 9001:2015 certified, ensuring that our processes adhere to international quality standards. We also comply with ISO 27001 for data security, making us a trusted partner for projects involving sensitive intellectual property.

One-Stop Service Solution

We offer a full range of services, from design and prototyping to final production and post-processing. Our comprehensive approach ensures that clients receive seamless service, minimizing delays and maximizing efficiency.

Industry Experience and Expertise

With over a decade in the industry, we have accumulated extensive experience in precision parts machining. Our team of experts is dedicated to delivering exceptional results, tailored to the specific needs of each client.

Case Studies: Real-World Applications

GreatLight CNC Machining Factory has successfully served various industries, including automotive, aerospace, medical devices, and high-end consumer electronics. Our ability to deliver high-quality, precision parts has made us a trusted partner for many leading companies.

Automotive Industry

In the automotive sector, we have worked on projects involving engine components and chassis parts, delivering parts that meet the strict requirements of the industry.

Aerospace

Our precision machining capabilities have been utilized in the production of aerospace components, where reliability and precision are paramount.

Medical Devices

We have extensive experience in manufacturing medical device components, ensuring that all parts meet the stringent standards of the medical industry.

Conclusion

GreatLight CNC Machining Factory is your ideal partner for precision parts machining and customization. With our advanced technology, comprehensive quality management, and extensive industry experience, we are equipped to handle any machining challenge you may face. Visit GreatLight CNC Machining Services for more information.

Frequently Asked Questions (FAQ)

Q: Can Sculptris be used for CNC machining?

A: Sculptris is primarily a digital sculpting software and is not designed for CNC machining. However, the models created in Sculptris can be exported and then used with CAM (Computer-Aided Manufacturing) software to generate the toolpaths needed for CNC machining.

Q: What materials can GreatLight CNC Machining Factory work with?

A: We can work with a wide range of materials, including metals like aluminum, stainless steel, titanium, and various alloys, as well as plastics and composites.

Q: How long does the machining process typically take?

A: The duration depends on the complexity of the part and the quantity required. For simple parts, we can deliver within a few days, while more complex projects may take several weeks.

Q: What is the maximum size of parts you can machine?

A: Our maximum processing size is 4000 mm, allowing us to handle large components.

Q: Do you offer design services?

A: Yes, we provide design services to ensure that your parts are optimized for machining and meet your specific requirements.

Q: What kind of post-processing services do you offer?

A: We offer a variety of post-processing services, including grinding, polishing, anodizing, and painting, to ensure your parts meet the desired finish.

For more information and case studies, please refer to our LinkedIn page.