When exploring manufacturing options for plastic components, a common and crucial question arises: Can a CNC machine cut plastic, or will it melt during the process? The short answer is a definitive yes, CNC machines excel at cutting plastic, and with proper expertise and process control, melting is not an inevitability but a preventable challenge. At GreatLight Metal, where we specialize in high-precision, full-process manufacturing, machining engineering-grade plastics is a core competency. The real question isn’t if it can be done, but how to do it optimally to achieve perfect, burr-free parts without thermal deformation.

This article will demystify the science and art of CNC machining plastics, providing you with the knowledge to make informed decisions for your next project.

The Science Behind the Cut: Why Melting is a Risk

At its core, CNC machining is a subtractive manufacturing process where a rotating cutting tool removes material. This interaction generates heat. The fundamental challenge with plastics lies in their low thermal conductivity and low glass transition/melting temperatures compared to metals.

Heat Generation: Friction between the tool and the workpiece creates heat.

Poor Heat Dissipation: Plastics are excellent insulators. The heat generated at the cutting edge doesn’t dissipate quickly into the bulk material or through chips (which are less effective at carrying heat away than metal chips).

Low Melting Point: Many thermoplastics soften or melt at temperatures far lower than the heat generated during cutting. For example, Acrylic (PMMA) can start to soften around 160°C, while a tool edge can easily exceed this if not managed.

If this heat is not controlled, it leads to a chain of undesirable outcomes: localized melting, re-solidified “gumminess” on the tool or part, poor surface finish, dimensional inaccuracy, and even workpiece warping.

Mastering the Process: How Expert Machinists Prevent Melting

Preventing melting is a symphony of correct material selection, tooling strategy, machining parameters, and cooling techniques. Here’s how a seasoned manufacturer like GreatLight Metal approaches it:

1. Material Selection & Understanding

Not all plastics are created equal for machining. We categorize them by their behavior:

Thermoplastics (e.g., ABS, Nylon, Polycarbonate, PEEK, Acrylic/PMMA): These can be re-melted. They are more susceptible to heat buildup and require careful parameter control.

Thermosets (e.g., Phenolic, Epoxy, FR4/G10): These are cured and cannot be re-melted, making them generally more stable under machining heat but prone to chipping or cracking if tools are dull.

2. Optimal Tooling Geometry and Material

Sharp Tools are Non-Negotiable: Razor-sharp cutting edges reduce cutting forces and friction, the primary heat sources. Tools are inspected and changed frequently.

Specialized Geometry: Tools often feature high rake angles and polished flutes to allow clean, efficient chip evacuation. For plastics, O-flute or single-flute end mills are often superior as they provide larger gullets for chip clearance, preventing chips from re-cutting and generating more heat.

Tool Material: Solid carbide tools are preferred for their hardness, sharp edge retention, and ability to run at higher speeds.

3. Precise Machining Parameters (Feeds & Speeds)

This is the heart of the process. The golden rule is often “high RPM, high feed rate.”

High Spindle Speed (RPM): Allows each cutting edge to take a smaller, cleaner bite.

High Feed Rate: Ensures the tool is constantly moving forward, cutting new material rather than rubbing and generating friction heat on the already-cut surface. Finding the “sweet spot” is where experience counts.

4. Advanced Cooling and Chip Evacuation

Compressed Air or Mist Coolant: Using a flood of liquid coolant (common with metals) can be problematic for some hygroscopic plastics (like Nylon) which may absorb moisture and swell. Precise, high-pressure air blast is often the best solution. It serves three purposes: cools the tool and workpiece, blows chips away from the cutting zone, and eliminates the risk of liquid contamination. Oil-based mist systems can also be effective lubricants.

Effective Chip Evacuation: Ensuring chips are immediately cleared from the cutting path is critical to prevent re-cutting and heat accumulation.

5. Secure and Intelligent Workholding

Plastics are less rigid. Using vacuum chucks, custom soft jaws, or strategic support to minimize vibration and chatter is essential. Chatter not only ruins surface finish but also generates excessive heat.

CNC Plastic Machining: Common Materials and Their Characteristics

| Plastic Material | Key Characteristics | Machinability & Common Challenges | Typical Applications |

|---|---|---|---|

| Acrylic (PMMA) | Glass-like clarity, brittle. | Excellent when machined correctly; prone to cracking and melting if tools are dull or feeds are too slow. | Light guides, lenses, displays, prototypes. |

| Polycarbonate (PC) | High impact strength, tough. | “Gummy” and can melt if not managed; requires sharp tools and high feed rates. | Safety shields, automotive components, electronic housings. |

| ABS | Good toughness, easy to finish. | Fairly easy to machine; can melt and leave stringy chips. | Prototypes, enclosures, consumer product parts. |

| Nylon (PA) | Wear-resistant, tough, slightly hygroscopic. | Machines well but can be abrasive; heat management is key to prevent softening. | Gears, bushings, industrial components. |

| PEEK | High-performance, high heat & chemical resistance. | Excellent machinability for a high-temp plastic; requires robust parameters but is very stable. | Aerospace, medical implants, semiconductor parts. |

| PTFE (Teflon) | Very soft, low friction, high chemical resistance. | Requires extremely sharp tools and specific techniques to avoid deformation; chips are not free-flowing. | Seals, gaskets, insulating parts. |

| Delrin (POM/Acetal) | High stiffness, low friction, dimensionally stable. | Known for excellent machinability, producing clean, precise parts with minimal burr. | Precision gears, bearings, mechanical assemblies. |

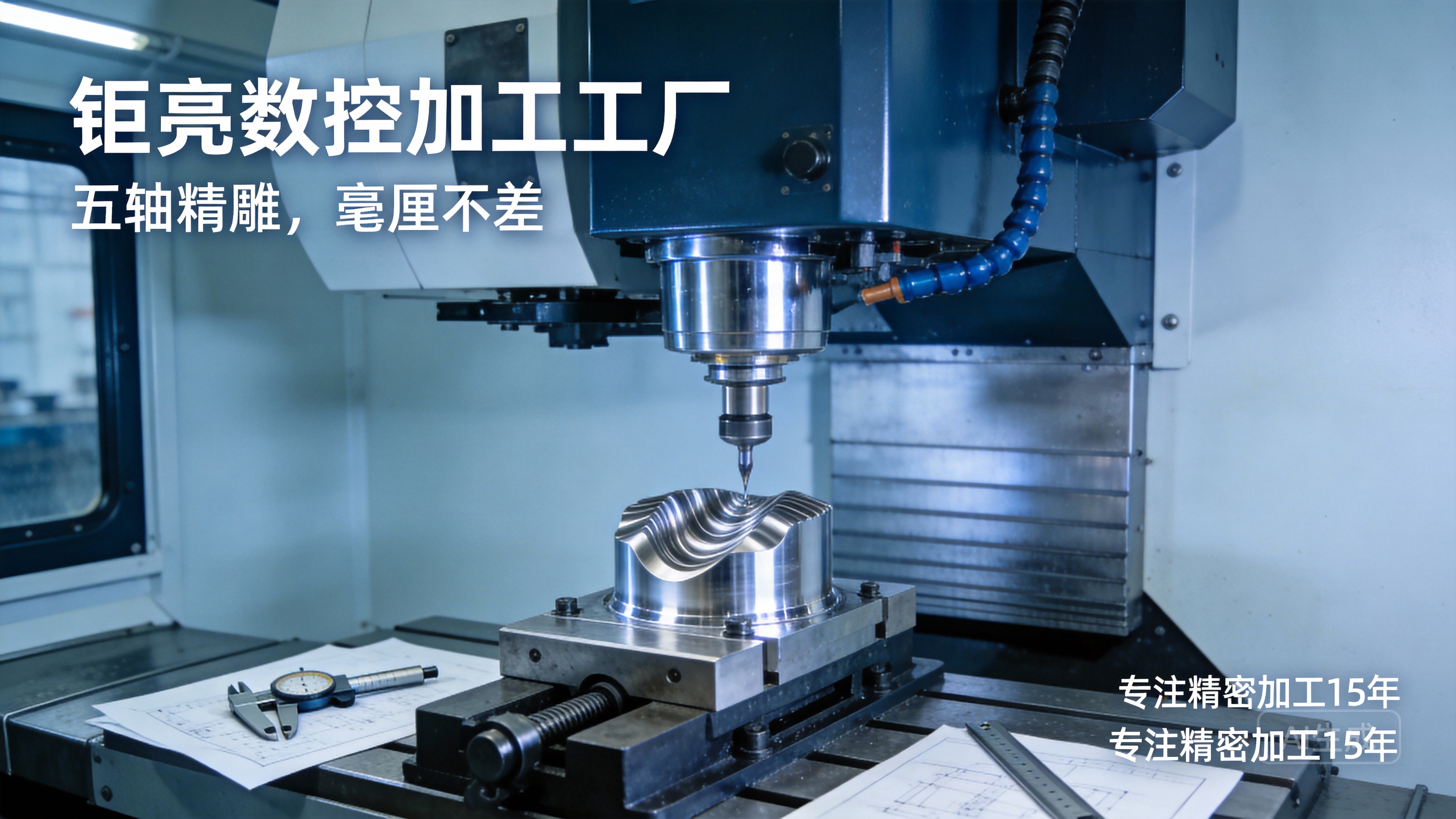

Why Partner with a Specialist Like GreatLight Metal for Plastic CNC Machining?

While a basic CNC router can cut plastic, achieving high-precision, high-reliability results for critical components demands deep expertise. Here’s what we bring to the table:

Material Science Expertise: We don’t just cut plastic; we understand its polymer structure, thermal behavior, and post-machining tendencies (like stress-relief or moisture absorption).

Process Optimization Library: With over a decade of experience, we have refined machining parameters and toolpaths for a vast array of engineering plastics, stored in our proprietary process library to ensure consistency.

Integrated One-Stop Solution: Your part may require more than just cutting. We provide full-process services including precision machining, post-processing (sanding, polishing, vapor smoothing for ABS), annealing for stress relief, and even complementary 3D printing (SLA, SLS) for prototypes or complex geometries not suited for subtractive methods.

Rigorous Quality System: Our ISO 9001:2015 certified quality management system ensures every step—from material certification to final inspection with our CMM and vision systems—is controlled. For medical or automotive plastics, our adherence to ISO 13485 and IATF 16949 frameworks provides an additional layer of trust.

Engineering Partnership: Our team acts as an extension of your R&D department. We can advise on design for manufacturability (DFM) for plastics, suggesting optimal wall thicknesses, radii, and feature designs to ensure your part is not only manufacturable but performs flawlessly.

Conclusion

So, can a CNC machine cut plastic? Absolutely. It is one of the most precise and reliable methods for creating functional prototypes, end-use parts, and complex components from engineering-grade plastics. The specter of melting is not a barrier but a process variable that is meticulously controlled by experienced manufacturers through a combination of sharp tooling, optimized cutting parameters, effective cooling, and deep material knowledge.

For projects where precision, reliability, and surface quality are paramount, partnering with a specialist like GreatLight Metal transforms this technical challenge into a routine, high-quality outcome. We provide the confidence that your plastic components will be machined to exact specifications, free from thermal defects, and ready to perform in your application.

Frequently Asked Questions (FAQ)

Q1: Is CNC machining or 3D printing better for plastic parts?

A1: It depends on your needs. CNC machining offers superior strength, tighter tolerances (down to ±0.001″ / ±0.025mm), better surface finishes, and uses solid, isotropic engineering-grade plastics. It’s ideal for functional parts, high-wear applications, and low-to-medium volume production. 3D printing excels at ultra-complex geometries (like internal lattices), is faster and more cost-effective for very low volumes (1-10 pieces) or prototypes, and has no tooling cost. At GreatLight Metal, we offer both services and can guide you to the best technology for your project.

Q2: How do you deal with burrs when machining plastic?

A2: Prevention is the first step: sharp tools and correct feeds/speeds minimize burr formation. For removal, we use a variety of post-processing techniques depending on the plastic: manual deburring tools, cryogenic deflashing, tumbling, or specialized chemical smoothing processes for materials like ABS.

Q3: My plastic part warped after machining. What happened?

A3: Warping is typically caused by internal stress relief or thermal stress. The machining process can release stresses inherent in the plastic sheet or rod stock, or excessive localized heat can cause differential expansion/contraction. Solutions include using stress-relieved stock, optimizing machining parameters to reduce heat, annealing the part after rough machining, and employing strategic clamping to minimize distortion.

Q4: Can you machine plastic to the same tight tolerances as metal?

A4: While plastics are more dimensionally sensitive to temperature and humidity changes, with a controlled environment and expert process control, very tight tolerances are absolutely achievable. For critical features, we regularly hold tolerances within ±0.001″ (±0.025mm) on stable engineering plastics like PEEK or Acetal. Environmental control in our measurement lab is key to verifying these tolerances accurately.

Q5: What file format do you need to provide a quote for a plastic CNC part?

A5: We prefer 3D solid model files (e.g., .STEP, .IGES, .X_T) as they contain the most complete geometric data. 2D drawings (.PDF, .DWG) with critical dimensions and tolerances are also extremely valuable. Simply upload your files through our quotation platform to get a comprehensive DFM analysis and a competitive quote.