3D printingThe ability to create complex, personalized objects on demand inspires the desire to own3D printers and the interest in using professional services make them a key tool in modern product manufacturing and development. Most of the time, when deciding whether to invest in a 3D printer or hire a printing service, consumers consider short-term costs to meet their current needs. Besides cost, there are many other factors to consider, including expertise, time, focus, and long-term goals.

cost

3D printed piggy bank (Source: Shapeway Blog)

Budget is basically one of the first things to consider. There are distinct advantages and disadvantages to purchasing a printer and using a service.

Buy3D printers can require a significant initial investment. While entry-level models start at around a thousand yuan, professional-grade machines can cost tens of thousands of yuan. Added to the initial cost are ongoing expenses such as materials, maintenance and potential repairs that add up over time.

On the other hand, if you want to useThe cost of 3D printing services can be shocking, especially for metal parts, remember that the price includes expertise, material cost, printing time and any additional services (like initial consultation or post-processing). This can be expensive for regular users, but it’s ideal for occasional or one-off project users. Additionally, printing service customers have access to advanced printing technologies and materials without the costs of owning high-end equipment.

To summarize: If you plan to print a lot, buy a printer. Call for service if you only use your printer occasionally or have a one-off project that requires advanced skills or high-end specialized equipment.

Expertise and learning curve

3D printing gets complicated… remember that? (Image: Loubie)

Besides cost, another major factor to consider is your level of expertise and, if you’re a beginner, how much time and effort you’re willing to put in to get something out of it.

As a printer owner, you will need to learn how to use the machine (don’t worry, some are as simple as plug-and-play), troubleshoot, manage printer settings, and optimize the printer. ‘impression. This often involves understanding complex software, maintaining printers, and troubleshooting common problems such as failed prints and hardware jams. Although the learning curve can be steep, for those who enjoy hands-on work and want to acquireFor people with technical skills in 3D printing, this provides a rewarding experience. Over time, users gain insights into the process, allowing for more creative control and customization.

Additionally, because the service provider takes care of the entire printing process, from setup and calibration to post-processing, users can spend their time designing the final product rather than to the technical details of its manufacture. In fact, you don’t need to know anything aboutKnowledge of 3D printing is sufficient to use the service. Many companies will guide you in selecting techniques and materials, or at least provide you with a library of resources.

Relying on the professionalism of a service is especially beneficial for those who need high-quality printing or plan to work with difficult materials and don’t have time to learn the intricacies of the technology involved. But keep in mind that relying on a service means giving up some control over the printing process, scheduling, and the ability to adjust in real time, so it may not be right for everyone.

To summarize:Buy3D printers are about having or developing expertise, but with more control and flexibility. Using a service is a better option for those who want the end product without worrying about gaining the necessary expertise.

frequency andquantity

Merit3D orders 1 million parts from Adhésive Technology (Source: Merit3D)

Another important factor to consider is how often and how much you plan to print. Buy3D printers are ideal for those who plan to print in large quantities because you have multiple projects or need to print a design multiple times. Once the initial investment is made, the cost per print is limited to materials, making it more economical in the long run. Let’s be real, it’s also more practical. You have complete control over when and how much you print, and you can make adjustments at any time, which is ideal for iterative designs and adjustments.

If you only plan to print a few items, purchasing a printer may not be the best option for you. to use3D printing services, while potentially more expensive per print, are more convenient because no long-term commitment is required. Printing services offer flexibility and scalability and are also ideal for occasional or large-scale projects.

To summarize: Need to print a lot? Buy a printer! Only print occasionally, or is the design too large or complex for your skills? Please use the printing service!

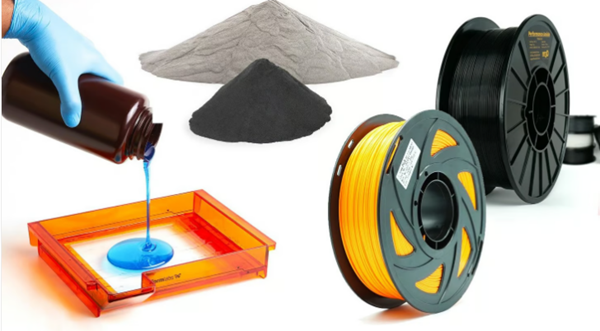

Quality and diversity of materials

Buying a machine and using a service have distinct advantages and disadvantages when it comes to the quality and materials used in the design.

BuyA 3D printer allows you to start printing immediately, but without spending a fortune on a materials library, you won’t be able to access the wide variety of materials that service providers offer. That’s not a problem, though, if you know everything will be carbon fiber-infused nylon. But it’s difficult to know at the start which material you actually need, and new materials are constantly appearing on the market. Additionally, the variety of materials available with a brand of machine may be limited to commonly available options or even exclusive to that brand.

When it comes to quality, most first purchasesPeople using 3D printers often start with FDM (or filament) 3D printers, which are the easiest to learn but do not offer industrial quality.

on the contrary,3D printing services offer you a wider range of materials and higher quality printing technologies, such as SLA (resin-based) or SLS (powder-based) printing, which produce better results. precise and professional quality. Printing services often provide industrial-grade printers that are unavailable to the average consumer. They can handle advanced materials such as metal, carbon fiber composites or flexible resins, giving you the flexibility to choose the best material for your specific project. That being said, these options generally have a higher cost per print and you should rely on their professionalism and timeliness.

To summarize: Want full control and convenience? So buy it! Need high quality prints or specialty materials? So call a service provider!

time and convenience

(source:PhilippHee via Printables)

Time and convenience don’t mean the same thing to different people. So you may have different priorities when deciding whether or not to buy a printer. own one3D printers provide instant access to the printing process, which is especially useful for those who need to iterate quickly, for small projects, or for regular use.

If you know what you’re doing, you can start printing at your convenience, make adjustments in real time, and have complete control over how your product ends without having to wait for outside service. but,3D printing can be a slow process and you still need to spend time on setup, calibration, troubleshooting, and post-processing tasks. For larger or more complex prints this can be very complicated.

On the other hand, with just a click of a button, you can send your design to a service provider, sit back, relax, move on to other designs, go on vacation or do other things, and receive the product directly to your doorstep. . This is especially beneficial for those who don’t print often or don’t have the expertise or patience to maintain a printer, or who don’t have enough space for a printer and its accessories. Some printers are noisy, produce toxins, or require extensive ventilation systems to operate safely.– Not everyone has access to it. However, outsourcing the process results in longer waiting times, which can range from a few days to several weeks depending on the complexity of the project and the workload of the service provider. But maybe that just means booking a longer vacation.

To summarize: Do you have space, expertise and want to quickly print large quantities of documents? Buy a printer! Do you want to spend your time doing something else? Use the Services.

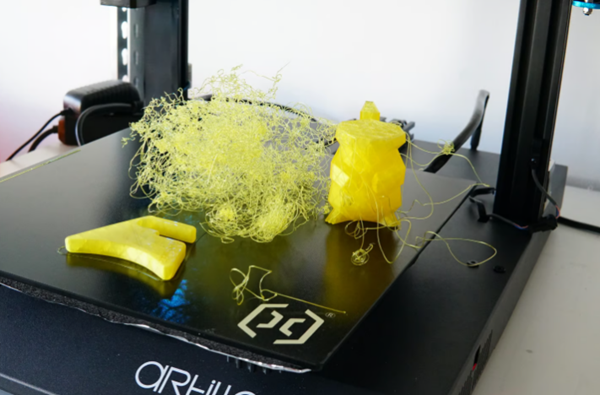

long term goals

Automatic system detection3D printing failed, so no more Pikachu on a stick (Source: All3DP)

We strongly recommend that you think about your long-term goals before investing in a printer. Do you or can you imagine yourself being one of those people who likes to make lots of prints, refine prototypes, experiment with materials, speeds, nozzles to get the right result? If so, owning a printer will be a wise decision. This is especially true if your final product requires iterative design work or customization and you want to avoid duplicate service costs.

On the other hand, if you have a highly specialized design or need high-end materials or technology beyond your expertise, use3D printing services may be more suitable. It’s ideal for businesses or individuals who need high-quality, industrial-grade printing but don’t have the ongoing need to justify owning a printer.

Bottom line: If you’re as interested in the printing process as you are in the final print, you might want to consider purchasing one. If you simply want a print without knowing all the details of its production, it is best to contact a service provider.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.