The automotive industry is experiencing a continuous evolution towards greater sustainability, and3D printing is crucial in this transformation. Thanks to additive manufacturing, companies can create greener, lighter and more efficient components. This innovation helps reduce the carbon footprint and paves the way for a greener future.

An example isBMW M Visionary Materials seats, which recently won the Altair Enlighten Award in the “Sustainable Processes” category at the Michigan Automotive Research Center Symposium. The annual awards recognize innovative solutions in the automotive industry that aim to reduce carbon, water and energy consumption while promoting material recycling. Additive manufacturing was key to the eco-friendly production of this seat, allowing BMW to eliminate support structures and chemical treatments.

The Altair Enlighten Award recognizes the BMW Group’s progress in innovation (Image source: BMW Group)

The Visionary Materials seats were designed in collaboration with the BMW design team responsible for the color and material concept, as well as various partners, including Management Consulting GmbH, Bcomp Ltd, Gradel Light Weight Sàrl and Lasso Ingenieurgesellschaft. Falco Hollmann, Head of Innovation for Lightweight Design and Sustainability at BMW M GmbH, accepted the award and said: “Today we are showing what is possible tomorrow with existing technology and materials to intensify our efforts. Reduce emissions and save resources. it’s simply about replacing materials, but also about designing with circularity in mind. »

The team’s work focuses on using plant-based materials, optimizing recyclability and creating attractive designs that combine quality, lightness and functionality. The seat is intended to pave the way for future process developments, particularly in sustainable seat design.

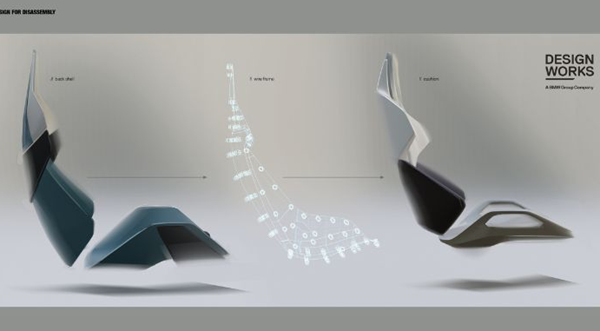

The seats are designed to be easily removed (Image: BMW Group)

Additionally, the carbon footprint is reduced through additive manufacturing and the use of robotic wound support structures based on composite fibers and natural materials.90%. The simplicity of the modules and the use of unmixed materials also promote recycling.

Continuous optimization of the process chain is crucial for the success of the project. On this subject, the head of automotive development at BMWRoberto Rossetti highlights: “One of our biggest lessons was the balance between how to model our process chains to generate missing primary data. The collected data provided new insights into current challenges and future process design. These experiences provide a solid basis for increasing sustainability and developing innovative solutions for future mobility” Find out more about BMW M Visionary material seats here.

Image source: BMW Group

What do you think about sustainable seats and their use in manufacturing?What do you think of 3D printing? Share your opinion in the comments to the article

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.