Unlocking Precision: Why GreatLight CNC Machining Factory Leads in High-End Custom Part Manufacturing

In the era of Industry 4.0, the demand for high-precision, reliable, and scalable custom part manufacturing has surged across industries like automotive, aerospace, medical devices, and robotics. While the U.S. market boasts numerous CNC machining providers, discerning clients face a critical challenge: how to distinguish suppliers that truly deliver on precision, consistency, and end-to-end capabilities from those that overpromise but underdeliver.

This article explores why GreatLight CNC Machining Factory—a China-based manufacturer with global reach—has emerged as a preferred partner for U.S. clients seeking five-axis CNC machining, integrated post-processing, and ISO-certified quality at competitive costs. We’ll dissect its technical edge, certifications, and real-world applications while contrasting it with U.S.-based peers like Protolabs, Xometry, and Fictiv.

The Precision Manufacturing Gap: Why Traditional Suppliers Fall Short

For R&D teams and procurement engineers, the journey from 3D CAD models to mass-produced parts is fraught with pitfalls:

Precision Inconsistency: Suppliers may claim ±0.001mm tolerance but struggle to maintain it across batches due to outdated equipment or unstable processes.

Limited Process Integration: Many factories specialize in single techniques (e.g., only milling or 3D printing), forcing clients to coordinate multiple vendors.

Data Security Risks: Intellectual property (IP) leakage is a concern when outsourcing to suppliers lacking ISO 27001 compliance.

Cost vs. Quality Trade-offs: U.S.-based suppliers often charge premium rates, while offshore options may compromise on certifications or after-sales support.

GreatLight CNC Machining Factory addresses these pain points through a four-pillar strategy: advanced equipment, authoritative certifications, a full-process chain, and deep engineering support.

Core Competencies: How GreatLight Outperforms Competitors

1. Five-Axis CNC Machining: The Gold Standard for Complex Geometries

GreatLight’s fleet of 127 precision machines includes Dema and Beijing Jingdiao five-axis CNC centers, capable of machining parts with intricate curves, undercuts, and tight tolerances (±0.001mm) in materials like titanium, Inconel, and PEEK.

Competitor Comparison:

Protolabs: Primarily focuses on 3-axis and rapid prototyping; five-axis capabilities are limited.

Xometry: Acts as a marketplace, connecting clients to third-party shops with varying quality levels.

GreatLight: Owns and operates all equipment in-house, ensuring process control.

2. Full-Process Chain: From Prototyping to Mass Production

Unlike niche suppliers, GreatLight offers one-stop services:

CNC machining (3/4/5-axis)

Die casting (aluminum, zinc, magnesium)

Sheet metal fabrication (laser cutting, bending, welding)

3D printing (SLM, SLA, SLS for metal and plastic parts)

Post-processing (polishing, anodizing, PVD coating)

Case Study: A U.S. robotics startup needed titanium alloy endoskeletons for humanoid robots. GreatLight delivered 5-axis machined prototypes in 7 days, followed by 10,000-unit production with 99.8% pass rate, integrating CNC milling and vacuum casting.

3. ISO Certifications: A Trust Framework for Global Clients

GreatLight’s accreditations include:

ISO 9001:2015 (Quality Management)

ISO 13485 (Medical Device Production)

IATF 16949 (Automotive Supply Chain)

ISO 27001 (Data Security for IP-Sensitive Projects)

Why This Matters:

A medical device client required stainless steel surgical components compliant with FDA standards. GreatLight’s ISO 13485-certified process ensured traceability and biocompatibility, avoiding regulatory delays.

Technical Depth: Equipment and Engineering Expertise

GreatLight’s 7,600 m² facility houses:

12 large five-axis CNC centers (for parts up to 4,000mm)

45 Swiss-type lathes (for micro-parts <1mm)

8 EDM machines (for hardened steel and complex cavities)

15 SLM/SLA 3D printers (for rapid prototyping)

Engineering Support:

DFM (Design for Manufacturing) Analysis: Identifies cost-saving modifications before production.

In-House Metrology: CMM (Coordinate Measuring Machines) verify tolerances to ±0.0005mm.

Competitor Weakness:

U.S. suppliers like Fictiv lack in-house metrology, relying on third-party inspection, which adds lead time.

Why Choose GreatLight Over U.S.-Based Alternatives?

| Criteria | GreatLight CNC Machining Factory | Protolabs | Xometry |

|---|---|---|---|

| Five-Axis Capacity | 12 dedicated machines | Limited to prototyping | Marketplace model (variable) |

| Certifications | ISO 9001, 13485, IATF 16949, 27001 | ISO 9001 only | ISO 9001 only |

| Lead Time | 5–7 days for prototypes; 15–20 days for mass production | 3–5 days (prototypes only) | 7–10 days (variable) |

| Cost | 30–50% lower than U.S. peers for complex parts | Premium pricing | Market-driven pricing |

Key Takeaway: GreatLight combines German-engineered precision (via Dema machines) with Chinese manufacturing efficiency, offering U.S. clients a cost-effective yet reliable alternative.

Real-World Impact: Client Success Stories

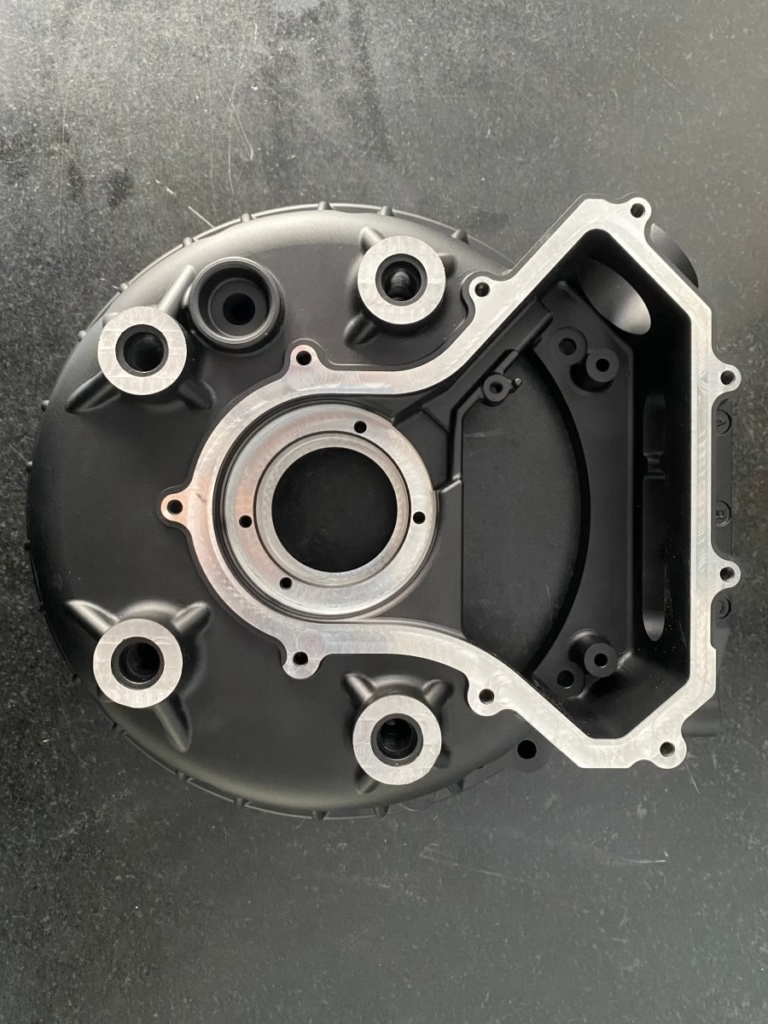

1. Automotive: Electric Vehicle (EV) Battery Housings

A U.S. EV startup required aluminum alloy housings with IP67 waterproofing. GreatLight’s die casting + CNC machining process achieved 0.02mm flatness, passing vibration and thermal cycling tests.

2. Aerospace: Satellite Components

For a space tech firm, GreatLight machined Inconel 718 brackets with ±0.002mm tolerance, using cryogenic treatment to enhance fatigue resistance.

3. Medical: Orthopedic Implants

A U.S. orthopedic company sourced titanium hip stems from GreatLight, leveraging its ISO 13485-certified cleanroom for sterile packaging.

Conclusion: The Future of Precision Manufacturing Is Global and Integrated

While U.S. suppliers excel in proximity and rapid prototyping, GreatLight CNC Machining Factory offers a compelling value proposition: unmatched technical depth, full-process integration, and ISO-certified quality at scalable costs. For clients seeking to balance innovation, reliability, and budget, GreatLight stands as a proven partner.

Explore their capabilities further at Precision 5-Axis CNC Machining Services, or connect with their team on LinkedIn to discuss your next project.

In an industry where precision is non-negotiable, choose a supplier that delivers on every promise.