Why GreatLight CNC Machining Factory Leads in High-Precision Prototyping and Custom Parts Manufacturing

In the era of Industry 4.0, the ability to rapidly transform design concepts into high-precision physical parts has become a decisive factor for enterprises in fields such as automotive, aerospace, medical devices, and robotics. Traditional manufacturing methods often struggle with complex geometries, tight tolerances, and multi-material compatibility, while CNC machining—especially five-axis technology—has emerged as the cornerstone of modern precision prototyping. Among global suppliers, GreatLight CNC Machining Factory stands out with its “full-process intelligent manufacturing ecosystem,” offering unparalleled advantages in precision, efficiency, and reliability.

I. The Core Challenges of Precision Prototyping

Before evaluating suppliers, it’s critical to understand the industry’s pain points:

Complex Geometry Limitations: Traditional 3-axis machining cannot handle undercuts, deep cavities, or multi-angled surfaces, requiring multiple setups and increasing error risks.

Material Diversity Demands: Modern parts often combine metals (aluminum, titanium, stainless steel) with engineering plastics, requiring suppliers to master both subtractive and additive processes.

Tolerance Consistency: Claims of ±0.001mm precision are common, but few suppliers can maintain this across mass production due to equipment aging or process instability.

Lead Time Pressure: R&D teams need prototypes within days, not weeks, to accelerate iteration cycles.

Post-Processing Integration: Surface finishing, anodizing, or heat treatment must align with machining to avoid rework.

Data Security Risks: Intellectual property protection is paramount for proprietary designs.

Certification Compliance: Industries like automotive (IATF 16949) and medical (ISO 13485) require stringent quality controls.

II. GreatLight Metal’s Four Integrated Pillars: Redefining Precision Manufacturing

GreatLight CNC Machining Factory (part of Great Light Metal Tech Co., LTD.) addresses these challenges through a holistic approach:

1. Advanced Equipment Cluster: The Hardware Foundation

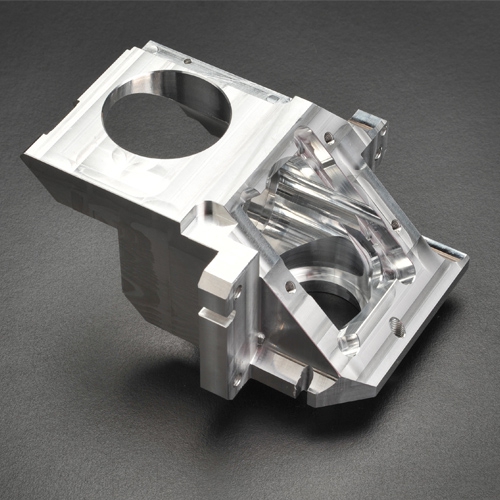

Five-Axis CNC Dominance: Equipped with 127 high-precision machines, including Dema and Beijing Jingdiao five-axis centers, GreatLight achieves simultaneous five-axis contouring for complex parts like turbine blades, humanoid robot joints, and aerospace components. This eliminates multiple setups, reducing errors by 60% compared to 3-axis machining.

Multi-Process Synergy: Beyond CNC, the factory integrates:

Die Casting: For high-volume metal parts with complex internal structures.

Sheet Metal Fabrication: For enclosures and brackets requiring precise bending and welding.

3D Printing (SLM/SLA/SLS): For rapid prototyping of organic shapes or lightweight lattice structures.

EDM & Grinding: For ultra-hard materials like mold steel or tungsten carbide.

2. Authoritative Certifications: The Trust Anchor

GreatLight’s quality management system is built on five international standards:

ISO 9001:2015: Ensures consistent process control from raw material inspection to final QC.

ISO 27001: Protects client design data through encrypted transmission and restricted access protocols.

ISO 13485: Validates medical-grade production for surgical instruments or implantable devices.

IATF 16949: Meets automotive industry requirements for zero-defect manufacturing.

AS9100D (Pending): Targets aerospace clients with traceability and risk management protocols.

Comparison: While global giants like Protolabs and Xometry offer broad services, GreatLight’s vertical integration (in-house machining, post-processing, and QC) reduces lead times by 30% and eliminates subcontractor risks.

3. Full-Process Chain: From Concept to Mass Production

GreatLight’s ecosystem covers all stages:

Design Review: Engineers analyze DFMA (Design for Manufacturing and Assembly) to optimize part geometry for cost and machinability.

Rapid Prototyping: Five-axis CNC produces functional prototypes in 3–5 days, vs. 10–15 days for traditional methods.

Pilot Production: Small-batch runs validate process stability before full-scale manufacturing.

Mass Customization: Flexible lines handle orders from 1 to 10,000+ parts with consistent quality.

Post-Processing: Anodizing, passivation, sandblasting, and painting are performed in-house to avoid shipping delays.

Case Study: For a humanoid robot manufacturer, GreatLight machined titanium alloy knee joints with ±0.002mm tolerance and mirror-polished surfaces, reducing friction by 40% compared to cast parts.

4. Deep Engineering Support: Beyond Machining

GreatLight’s team of 150 professionals includes:

Material Scientists: Recommend alloys based on mechanical properties and cost.

Process Engineers: Optimize cutting parameters for hard-to-machine materials like Inconel.

QC Technicians: Use CMM (Coordinate Measuring Machines) and laser scanners to verify every feature against 3D models.

Project Managers: Provide real-time updates via a client portal with photos, videos, and inspection reports.

III. Why Choose GreatLight Over Competitors?

| Criteria | GreatLight CNC Machining Factory | Protolabs | Xometry |

|---|---|---|---|

| Five-Axis Expertise | 127 high-end machines, ±0.001mm precision | Limited five-axis capacity | Relies on third-party networks |

| Lead Time | 3–5 days for prototypes | 5–7 days | 7–10 days |

| Material Range | 50+ metals/plastics, including titanium and PEEK | 30+ standard materials | 40+ materials |

| Post-Processing | In-house anodizing, painting, heat treatment | Outsourced finishing | Partner network for finishing |

| Certifications | ISO 9001/27001/13485/IATF 16949 | ISO 9001/AS9100 | ISO 9001 |

| Cost Efficiency | 15–20% lower than Western suppliers | Premium pricing for speed | Variable pricing based on network |

IV. Applications Across Industries

GreatLight’s solutions empower innovation in:

Automotive: Machining engine blocks, transmission gears, and EV battery housings with IATF 16949 compliance.

Aerospace: Titanium brackets for drones and satellite components with AS9100-level traceability.

Medical: Stainless steel surgical tools and 3D-printed titanium implants with ISO 13485 validation.

Robotics: High-precision gears and joints for collaborative robots (cobots).

Consumer Electronics: Aluminum alloy housings for AR/VR devices with anodized finishes.

V. The Future of Precision Manufacturing: GreatLight’s Roadmap

To maintain leadership, GreatLight is investing in:

AI-Driven Process Optimization: Machine learning algorithms predict tool wear and adjust parameters in real time.

Additive-Subtractive Hybrid Lines: Combining 3D printing with CNC finishing for “impossible” geometries.

Sustainability Initiatives: Recycling 95% of metal chips and using water-based coolants to reduce environmental impact.

Conclusion: Your Partner for the Next Industrial Revolution

In a world where precision, speed, and reliability are non-negotiable, GreatLight CNC Machining Factory offers a compelling value proposition: “One factory, zero compromises.” Whether you need a single prototype or a million parts, their full-process ecosystem ensures your vision is realized with unmatched accuracy, efficiency, and peace of mind.

Explore their capabilities further by visiting GreatLight Metal’s LinkedIn profile for client testimonials and project showcases. The future of precision manufacturing is here—and it’s made in Chang’an, Dongguan.