Manufacturer EOS has collaborated to develop the new Bauer REAKT helmet, which uses a custom 3D printed liner to provide better comfort and protection.

△Hockey helmet indication

Bauer Hockey is a well-known hockey equipment manufacturer headquartered in Canada with a history of over 90 years. The company mainly produces hockey shoes, sticks, protective equipment, gloves, helmets and other hockey equipment. Its products are renowned for their high quality, innovation and durability.

△Previously, some manufacturers also used different size foam liners in helmets

3D printing technology continues to innovate the sports equipment industry

Bauer is now using digital foam technology to combine its REAKT helmet liner design with EOS Selective Laser Sintering (SLS) 3D printing technology to achieve high-performance custom manufacturing. This design integrates the grid into the helmet padding, which can effectively reduce the weight of the helmet and improve breathability.

Mathieu, Senior Brand Manager, Protective Equipment, Bauer Hockey Dejardins said: “Every athlete’s head shape is unique, whether professional or amateur, which poses challenges in helmet design and production . Bauer is committed to innovating in the field of “mass customization”, and we work with other partners. , EOS launched the MyBauer custom hockey equipment program, which now includes custom helmet pads and is ready for mass production. Although digital foam technology is still relatively new, it allows us to be at the forefront of product innovation while avoiding other technologies and technology. manufacturing constraints.”

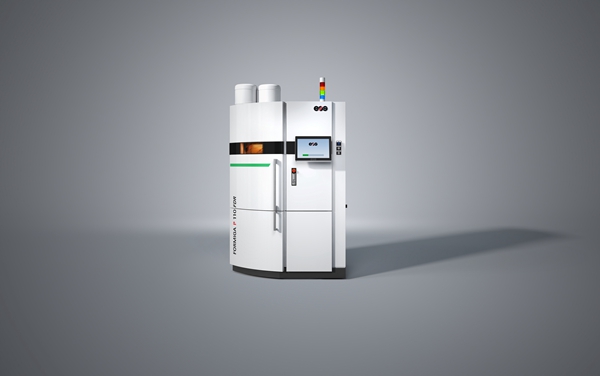

△FORMIGA P 110 FDR polymer SLS system

With the EOS SLS 3D printing process

Now, manufacturers can scan an athlete’s head to obtain a digital file, then use EOS’s selective laser sintering technology to print a helmet that fits the wearer’s head perfectly. The printed parts are then painted, finished and assembled to create a highly personalized helmet. This technology not only meets personalized needs, but also brings new ideas and methods to sports helmet manufacturing.

Bauer launched the REAKT helmet in the middle of the 2022 NHL season and invited NHL players Cale Makar and Jack Eichel to try it. The helmet is already available at 300 retailers worldwide and consumers can get a personalized helmet within four weeks. This custom production method can provide consumers with a more personalized experience, while providing hockey players with more comfortable, safer and more protective helmet options.

Dejardins added: “Bauer’s innovation is astonishing. In order to improve the comfort and protection of the helmet, they use 3D printing technology and digital foam technology. This is an innovative change in the sports equipment industry that is beginning to be widely used in protective equipment. We are proud of the successful application of digital foam in the production of high-quality helmets at Bauer. This project is a good example of improving traditional manufacturing and combining 3D printing technology with traditional manufacturing. the industry is moving forward. »

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.