As a key part of modern manufacturing, CNC machining centers have revolutionized the way parts are produced, providing unparalleled precision, efficiency and flexibility. For businesses and individuals who want to create complex parts with high accuracy, understanding the foundations of CNC machining centers is essential. In this article, we will dig into the world of CNC machining, explore its principles, applications and benefits, focusing on five-axis CNC machining, which is the pinnacle of manufacturing technology.

CNC or computer numerical control refers to the process of using a computer to control a machine tool. This technology allows precise automation of various machining operations, including milling, drilling, tapping, etc. The integration of computer-aided design (CAD) software and computer-aided manufacturing (CAM) software makes it easy for design to create complex parts, as the design can be directly converted into machining instructions.

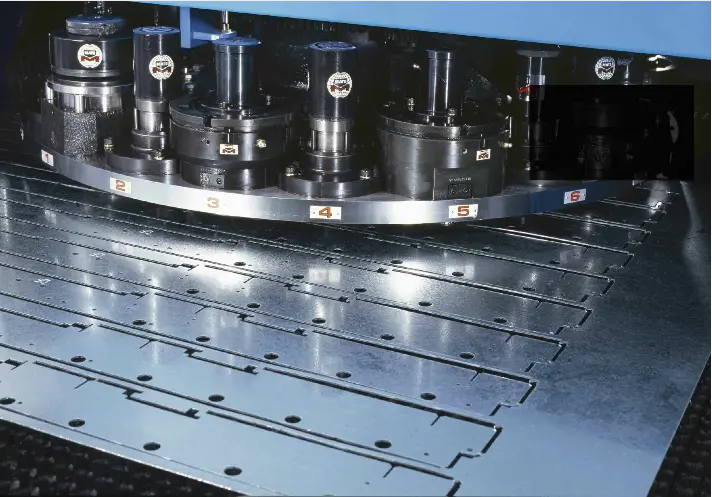

At the heart of CNC machining is the machining center itself, a universal machine tool that performs multiple operations on a single workpiece without repositioning or transferring parts to another machine. Among them, the five-axis CNC machining center stands out in the ability to manipulate cutting tools on five different axes, creating complex geometric shapes and shapes that traditional machining techniques will not be possible or extremely challenging.

The advantages of five-axis CNC machining are diverse. It provides enhanced accuracy, allowing parts with complex geometry and tight tolerances to be produced. It also improves efficiency by reducing the need for multiple settings and partial processing, saving time and minimizing the risk of human error. In addition, five-axis machining can handle a wide range of materials, from soft metals and plastics to hard and exotic materials, making it a versatile option in a wide range of industries including aerospace, automotive, medical and consumer goods.

For those who want to take advantage of the benefits of five-axis CNC machining, it is crucial to work with a professional manufacturer. As a leading five-axis CNC machining manufacturer, Light Light offers advanced equipment, cutting-edge production technology and a commitment to quality and customer satisfaction. With the ability to quickly customize and handle most materials, Great Light offers a one-stop post-processing and completion service to ensure that parts meet the exact specifications and requirements of the customer.

In short, CNC machining centers, especially those with five-axis functions, represent the forefront of manufacturing technology and provide unprecedented accuracy, efficiency and flexibility. By understanding the basics of CNC machining and the unique advantages of five-axis technology, businesses and individuals can unlock new possibilities for parts production, allowing easy implementation of complex geometry and high precision. Whether for prototyping, small-scale production or large-scale manufacturing, the five-axis CNC machining stance proves human creativity and the ruthless pursuit of innovation in manufacturing.

FAQs (FAQs)

What is CNC machining?

- CNC machining refers to the use of a computer to control the machine tool, so that various machining operations can be accurately automated.

What are the benefits of five-axis CNC machining?

- Five-axis CNC machining provides improved accuracy, increased efficiency, and the ability to generate complex geometric shapes and shapes in a single setup.

What types of materials can be processed by five-axis CNC machining?

- Five-axis CNC machining can handle a wide range of materials, including metals, plastics and exotic materials, making it versatile in a variety of industries.

Why is it important to work with a professional five-axis CNC machining manufacturer?

- Working with a professional manufacturer ensures access to advanced equipment, technology and expertise, as well as high-quality parts that meet certain requirements and specifications.

What services can a one-stop CNC processing provider provide?

- One-stop providers can provide processing services, post-processing and completion services to ensure that parts are fully completed in customer specifications.

- How can five-axis CNC machining help innovation in manufacturing?

- Five-axis CNC machining opens new possibilities for design and function in various industries through the production of complex parts with high precision and efficiency, thus aiding innovation.