Introduction to CNC iron processing

CNC iron processing is a highly accurate and effective method for the manufacture of metal parts, especially parts made of iron and its alloys. With the development of technology, CNC machining has become an important process in various industries, including automobiles, aerospace and construction. In this article, we will dig into the basics of CNC iron processing, its benefits, and services provided by professional manufacturers such as Great Light.

Understand CNC machining

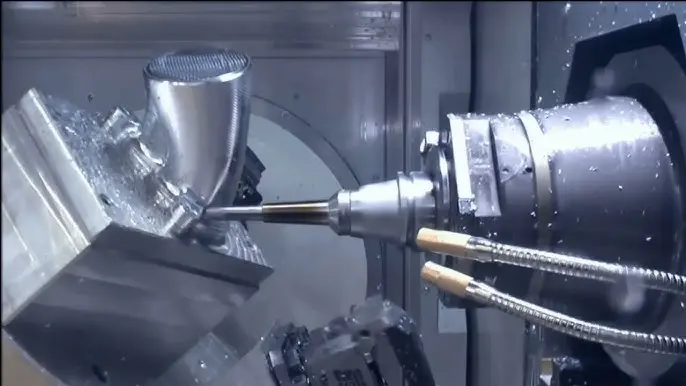

CNC stands for computer numerical control, which refers to the use of computer programs to control a machine tool. In CNC iron processing, computer programs are used to control the movement of the cutting tool to cut accurately and accurately. The process involves several steps, including designing parts, creating computer-aided design (CAD) files, and then using a CNC machine to cut and shape the iron material according to the design specifications.

Benefits of CNC iron processing

CNC iron processing offers a variety of benefits, including:

- High Accuracy and Accuracy: CNC machines can produce parts with precise dimensions and tolerances, making them ideal for applications where accuracy is critical.

- Improve efficiency: CNC machines can work continuously without fatigue, reducing production time and increasing productivity.

- Reduce labor costs: CNC machines can perform complex tasks with minimal human intervention, lower labor costs and increase profit margins.

- Improved Quality: CNC machines can produce parts with high surface finishes and minimal defects, reducing the need for post-processing and quality control.

Services provided by headlights

Great Light is a professional five-axis CNC machining manufacturer that provides a range of services including:

- Custom Precision Processing: Use a range of materials (including iron and its alloys) to manufacture parts according to customer specifications.

- Five-axis CNC machining: Great Light’s five-axis CNC machines can produce complex parts with multiple functions and angles, reducing the need for multiple settings and increased efficiency.

- Post-treatment and finishing services: Excellent lighting offers a range of post-treatment and finishing services, including grinding, polishing and coating to enhance the surface surface and performance of the parts.

in conclusion

CNC iron processing is a highly accurate and effective method for the manufacture of metal parts, providing a variety of benefits including high precision, improved efficiency, reduced labor costs and improved quality. Great Light is a professional five-axis CNC machining manufacturer that provides a range of services including customized precision machining, five-axis CNC machining, and post-processing and completion services. With its advanced equipment and production technology, Great Light is the first choice for customized precision machining, providing high-quality parts at competitive prices.

FAQs (FAQs)

Q: What is CNC iron processing?

A: CNC iron processing is a method of using computer numerical control (CNC) machines to make metal parts to cut and shape iron materials.

Q: What are the benefits of CNC iron processing?

Answer: The benefits of CNC iron processing include high precision, improved efficiency, reduced labor costs and improved quality.

Q: What services does lighting provide?

A: Great Light provides customized precision machining, five-axis CNC machining, and post-processing and completion services.

Q: What materials can be used in CNC iron processing?

A: A range of materials can be used in CNC iron processing, including iron and its alloys.

Q: How long does it take to process CNC iron?

A: The time required to complete a CNC iron processing project depends on the complexity of the parts, the materials used and the production volume.

Q: Is CNC iron processing expensive?

A: The cost of CNC iron processing depends on the complexity of the parts, the materials used and the production volume. Great Light offers competitive prices for its services.