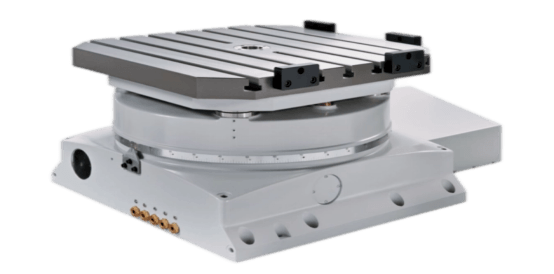

1. About the horizontal turntable and

The basic model of the traditional horizontal machining center has a three-axis structure and can only process one face at a time. If four-sided processing is required, a high-end horizontal machining center requires four working axes. XYZB connection to process complex parts. It is necessary to configure a four-axis rotary table; also to further improve the clamping and processing efficiency, the horizontal machining center is equipped with exchange table, multi-work table, etc. called horizontal rotary table).

Horizontal machining turntable is widely used in horizontal machining centers, multi-station machine tools, automatic lines, etc. It is the main functional component to complete lift, angular positioning, auxiliary processing, etc. Under the control of the host system, the horizontal machining turntable can realize high-precision fourth-axis machining of hole systems, slots or continuous special curved surfaces.

1. Composition and classification of four-axis rotary table

The four-axis rotary table generally consists of a worktable, a rotary table, a base, a support bearing, a locking mechanism, a rotary mechanism, a servomotor, a grid ruler, etc. The rotary exchange table also has a support, hydraulic lifting and positioning cone structure. Additionally, there are also support mechanisms for clearance elimination, inspection and testing, and feedback. There are many classifications of horizontal turntables. Generally, they can be divided into the following two types according to the driving and locking methods:

–The electromagnetic rotating worktable, driven by a torque servo motor and locked by an electromagnetic clutch, can realize continuous indexing. The minimum indexing unit of the turntable is 0.001° and can be linked to all four axes of XYZB at the same time. The driving principle is: the electromagnetic clutch starts, the work surface locking mechanism is released, the servo motor drives the worm and worm gear mechanism, and then drives the work surface to rotate 360 degrees, and the rotation is in place. the electromagnetic clutch is tightened and self-locking when the power is turned off, and the work surface is positioned and locked.

–The crank rotary table is driven by a servo motor to rotate. The gear plate is hydraulically driven for positioning and locking. The positioning rotation angle is determined by the number of teeth on the gear plate. the turntable used has a minimum indexing unit of 1º and is more expensive than the Low electromagnetic type. The driving principle is as follows: the hydraulic system supplies oil to disengage the upper and lower indexing gear disks in the turntable mechanism (also called platters and locking plates). The servo motor drives the transmission of the worm and worm mechanism, which in turn drives. 360 degree rotation of the work surface. , the worktable rotates in place, the hydraulic cylinder system returns the oil, and the upper and lower gear plates are combined and locked to complete the positioning and locking of the worktable.

2. Core technology

The technical objective of the horizontal processing turntable is the reliability of positioning and locking mechanism, the accuracy of positioning and repeated positioning, the transposition and exchange time, etc. its performance directly affects the structure and precision parameters of the entire machine equipment and pallets; supporting automatic line have relatively high interchangeability requirements. The essential components of the horizontal machining turntable, including gear disk, locking parts, and positioning and locking mechanisms, require high-precision equipment such as jig boring machines and vertical grinders, while drive motors, bearings, sensors, etc. be outsourced.

2. Market demand situation

At present, there is no unified annual production and sales data of horizontal processing turntables in China. According to the latest machine tool directory, the production of horizontal processing turntables in 2020 is 1,007 units, taking into account service and other support needs. The annual demand for horizontal processing stages is initially estimated to be 1,500 sets of tables and above.

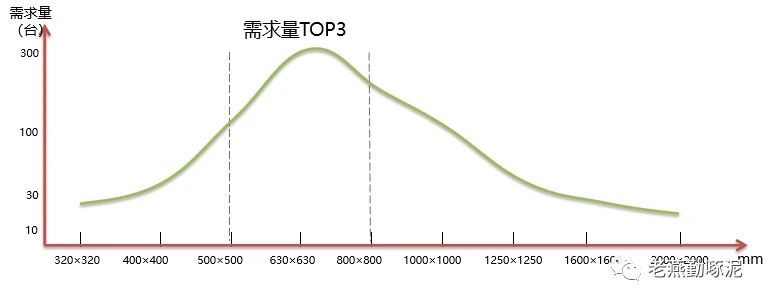

1. Distribution of demand

According to the size of the pallet surface of the workbench, the standard specifications are 320×320, 400×400, 1600×1600, 2000×2000, etc. Among them, the 500×500, 630×630 and 800×800 specifications are among the three most requested. Of course, support companies can provide turntables in special sizes depending on the customer’s equipment requirements.

2. Original classification

There are many horizontal processing turntable manufacturers at home and abroad. Horizontal processing turntables used by domestic metal cutting machine tool manufacturing companies can be divided into four categories based on their place of origin.

The first type of imported horizontal processing turrets. Currently, imported horizontal processing turrets mainly come from the European Union and Japan. These are mainly high-end products, such as Peiseler, CYTEC, SPIRSIN, FIBRO, Pascal and KITAGAWA, Tsudakoma. TSUDKOM, Sankyo and other international brands, maintaining the leading level in this field;

The second type of horizontal rotary table from Taiwan. Taiwan’s rolling functional parts industry started about 10 years later than the mainland, but its development level is higher than that of the mainland and has formed a mature industrial production scale. It is cost-effective and supports mid-range CNC machine tools in mainland China, and occupies about 50% market share. Representative brands of CNC turntables include GSA Xuyang, Detron, TJR, TANSHING, PARKSON, etc. ;

The third type of homemade horizontal processing turntable. As a core functional component, the performance of the horizontal processing turntable determines the quality of the machine tool to master the core technology, improve the quality of machine tools and reduce supply costs. delivery times, many machine tool enterprises at home and abroad adopt homemade horizontal processing such as Mazak, Okuma, Doosan, DMG MORI, Beijing Jingdiao, Genesis, Haitian Seiko, etc.

The fourth type of professional factory support equipment. With the increasing expansion of specialized collaborative production, some machine tool factories have chosen professional factory support equipment. The representative brands of domestic CNC turntables are Yantai Global, Gutian, Super Synchronous, Jiangsu Desu, Lanlan Technology. , etc. Due to the limited market size, similar product structure and similar manufacturing resource requirements, each supporting company specializes in the production of horizontal processing turntables, and also produces a series of functional components such such as CNC tool holders, vertical processing turntables, five-axis turntables. five-axis vinyl heads and turntables.

3. Development trends

In recent years, with the rapid development of China’s high-end manufacturing industry and national economy, the demand for processing large, complex and high-precision parts has increased. Four-axis horizontal machining has problems such as low processing efficiency and inability to ensure high-precision processing of complex parts. However, by installing a five-axis CNC turntable and a vertical/horizontal machining center composite worktable, four to four intensive processing is possible. five axes can be achieved. The use of five-axis turntables and composite worktables can improve production efficiency and achieve higher precision standards; It can simplify the five-axis machining process, avoid mutual interference of cutting tools during cutting, so that production can be completed smoothly and. can be used for the production of more complex parts. , five-axis, composite and precision are the future development trends of four-axis turntables.

Thousands of words have been written and I am a complete layman. I only have a preliminary understanding of the horizontal and vertical rotary table. This is a personal opinion and not a system. I accept criticism and corrections. exchange!

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.