In today’s fast-paced and competitive market, precision and speed are key factors that can make any organization successful or break the success. In the most accurate aerospace sector, companies need a reliable and effective way to produce high-quality metal parts. This is where aerospace CNC machining is located, providing cutting-edge solutions for precision and speed.

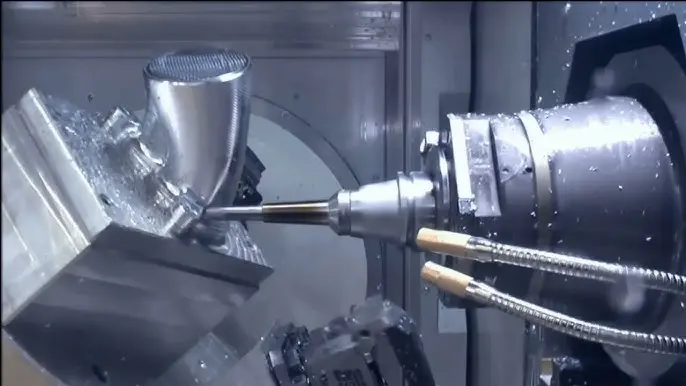

CNC machining or computer numerical control machining is a manufacturing process that uses a computer-controlled machine to perform various operations on a workpiece. In the aerospace industry, CNC machining is widely used to produce complex metal parts with high precision and accuracy. The process begins with creating a computer-aided design (CAD) model that is then used as input to the CNC machine to make parts.

One of the key advantages of aerospace CNC machining is its ability to produce parts with unparalleled accuracy and speed. Through traditional processing methods, it can take weeks or even months to produce part of it. By contrast, CNC machining can accomplish the same task in a few hours or days, which is an ideal solution for industries with ever-changing production demands.

Another important benefit of aerospace CNC machining is its ability to produce parts with complex geometric shapes and complex details. With advanced software and precision tools, CNC machines can create parts with complex functions, holes and surfaces, making them the ideal solution for aerospace applications where accuracy is critical.

From an excellent perspective, we focus on five-axis CNC machining, which allows us to produce complex parts with unparalleled accuracy and speed. Our advanced equipment and production technology enables us to overcome the limitations of traditional processing methods to provide our customers with high-quality metal parts in a timely and cost-effective manner.

From a very obvious perspective, we understand the importance of accuracy and speed in the aerospace industry. That’s why we have developed a comprehensive service offering that includes one-stop post-processing and completion, enabling us to meet the unique needs of our customers. With the help of a wide range of materials we can use, we can customize parts for a wide range of applications to ensure our customers receive the exact product they need.

In short, Aviation CNC machining is a game changer in the industry, providing unparalleled precision and speed. With our advanced equipment and production technology, Great Light is the ideal partner for companies seeking high-quality metal parts with precise specifications. If you want to outsource your CNC machining needs, then you can look for nothing. Contact us today to learn more about our services and let us help you unlock the full potential of your business.

FAQ:

Q: What is aviation CNC processing?

A: Aerospace CNC machining is a manufacturing process that uses computer-controlled machines to produce high-precision metal parts that are widely used in the aerospace industry.

Q: What are the benefits of aviation CNC processing?

A: Aerospace CNC machining provides unparalleled accuracy and speed to produce complex parts with complex details and geometric shapes in a timely and cost-effective manner.

Q: What makes Light’s five-axis CNC machining unique?

A: Great Light’s advanced five-axis CNC machining equipment and production technology enables us to produce high-quality metal parts with precision and speed, thus overcoming the limitations of traditional machining methods.

Q: Can excellent light custom parts be used in a variety of applications?

A: Yes, we can customize parts for a wide range of applications using a wide range of materials and advanced production technologies.

Q: How do I start with the CNC machining service at Great Light?

A: Simply contact us immediately to learn more about our services and to schedule an inquiry to discuss your specific needs.