Summary: Large allocation bearings are used in wind turbines and other energy industrial equipment, and in these applications, equipment has a severe work environment. In order to resist large dynamic loads, the rotary support roll can be hardened on the surface by induction heating and adopts a process without flexible belt to obtain a uniform heat treatment without soft belts. Compared to the traditional carburetor carburetor in frenace, induction hardening without soft belt is faster and energy consumption is lower, and a process has been developed for the induction treatment of ignition bearings in steel steel carbon means to obtain the same effect. The presence of the preheating coil, with an independent power supply, can adjust the heating rate to adjust the heating process according to the characteristics of the steel. The preheating function guarantees that the hardened layer is greater than 10 mm without reducing the speed or productivity of scanning. The mechanical monitoring system adjusts the coil position to compensate for the deformation of the part, ensuring uniform heating. The surface hardness test and metallographic detection are carried out for the exposure zones of different processes to check the consistency of the process. By preheating the sensor, surface overheating is avoided and a fine and uniform grain structure is obtained in the traditional zone of the soft belt.

1 preface

The aim of this study is to develop an induction hardening process adapted to large -scale rotary support for average carbon steel. Usually the steel used for bearings is mainly in high carbon chroboon steel, fuel steel, average carbon alloy steel or other types of steel for special purposes. Large oscillating bearings are treated on the surface to obtain a hardened layer. The hardened layer can ensure that the bearings bear high dynamic loads. At the same time, the surface hardening process means that the untreated cardiac part has good tenacity. The depth of the hardened layer is between a few millimeters and 10 mm, depending on the size and application of the bearing. Having a sufficiently deep hardened layer is a process requirement which must be guaranteed to meet the required load capacity for each specific application. Of course, too deeply, the hardened layer must also be avoided, because the too deep hardened layer will increase the risk of surface cracking during the caliber.

2 traditional carburee processes

Fuel steel is generally used to produce bearings. For such bearings, the hardened layer is obtained by carbureuring process. The carburetor in a high temperature oven and a long insulation time is not only high energy consumption but also for a long time, but also coarse the grains of the treated material. During this process, the transformation of hammer phase and the rapid cooling of the whole game will lead to a large deformation. For these reasons, the use of steel with low carbon content to provide large support cannot meet the requirements of the process. Average carbon steel is an appropriate choice. The surface of the rolling should be hardened by induction and must have a sufficient hard coat depth to reach the necessary mechanical properties.

3 induction hardening

Unlike fuel technology, induction hitching technology does not require heating from the whole room, but only treats the surface layer, so that the central part and its metallographic structure remain unchanged or have less deformation. Compared to fuel, induction hardening is a rapid process and energy saving. The heating is done by placing the conductive material in a magnetic field generated by an alternating current at high frequency through the inductance, generally an inductance in copper cooled by water.

A special appearance of induction heating is to directly generate heat sources on the room, that is to say that the magnetic field generated by the inductance generates Foucault currents on the surface of the room and heat the material of the part which must be treated by the resistivity of the equipment (joule) of the equipment. The heating depth generated is linked to the frequency of alternating current: the higher the frequency, the more the depth of the infiltration of the Foucault current. Combining the output voltage and the frequency of the induction power, the heating time, the quenching medium, the magnet driver and the shape of inductance, etc. With fully automated equipment controlled by the program to complete the heating of the specified area of the part and obtain it required the caliber profile and the dip.

4 soft band technologies

The working conditions of the rolling require stable mechanical properties and a layer of uniform hardening over the entire surface of the circumferential annular roller. A gentle band with surface hardness and lower mechanical resistance will cause wear likely to wear this area, causing a special zone of cracked nucleation and expansion. When the end of the heating path of the scan induction rides the starting point of the scan, the conventional scan induction heating process creates a soft zone which will temperate the already soaked material. Soft belt -free sweeping technology can meet the requirements of the rolling induction hardening process to eliminate beautiful sweets. The process without flexible belt uses two heating components, each equipped with two inductances, called preheating sensors and heating sensors, respectively. Each sensor has an independent power supply which can be defined as the output power required for the heating process. The two heating assemblies are capable of moving around the rolling roll, each covering half the bearing ring. The preheating and heating inductances are arranged parallel to the surface of the roller roller and are assured that the inductance and the roller are parallel in all cases by a rotating CNC mandrel mounted on the heating assembly connected to the inductance . Each spray unit is equipped with a main cooling spray and an auxiliary cooling spray. Inductances and coolant spraying devices must be designed specifically depending on the geometry of the rolling roll. The main cooling spray provides the rapid cooling required to carry out a transition from hammer phase, while the auxiliary cooling spray helps to complete the phase transition and cools the material at room temperature.

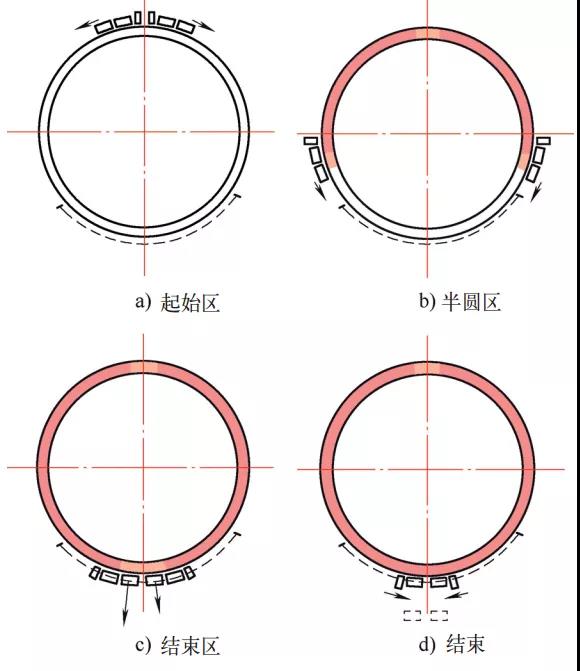

Figure 1 shows the location of the heating assembly in different stages of process. The heating begins at a point of the annular part, and the two heating components are close to each other. Figure 1a). At this stage, all the sensors are heated together. When the starting area reaches the temperature of the process extinction, the rotary platform stops swinging and the two independent heating components move in the opposite direction. At this time, the main sprayer opens and begins to quickly cool the surface of the starting area. When heated in stable scan mode, each heating assembly moves around half the circumference of the bearing (see Figure 1B). Adjust the scanning speed and heating power as a function of the process requirements to obtain the required hardened layer. The two heating assemblies move in the opposite direction of the rolling roll to a position opposed to the departure area, which is called the end zone. When the two heating assemblies are close to each other, the two pairs of preheating sensors are immediately adjacent to each other (see Figure 1c). Currently, the supply of the first preheating sensor of the heating assembly is interrupted and the preheating sensor is removed from the surface of the roller. The removal of a sensor creates a closer heating space for the two heating components. When the preheating sensor of the second heating assembly is adjacent to the heating sensor of the first heating assembly, the supply of the second preheating sensor is again extinguished while the inductor leaves the surface of the roller. The second preheating sensor covers the surface of the roller and is then heated by two heating sensors near each other (see Figure 1D). When the two heating sensors are closest to each other, the power is disabled and the platform platform is quickly moved so that one of the auxiliary showers covers the last section of heating roller. The constant gap between the inductance and the surface of the roller is the base to obtain a uniform heating mode.

Figure 1 Inductor position during the heating process

The rapid cooling and the transition of martensitis of the extinction process create stresses in the hardened layer, which will cause the bearing deformation, causing a change between the inductor and the roller during the heating process. To avoid this, a mechanical monitoring system is used. Each heating set is equipped with a follow -up device which remains in contact with the surface of the roller. When the heating assembly revolves around the bearing, the follow -up system measures the changes in the position of the surface of the bearing and compensates for the position of the sensor to maintain the constant space.

5 42CRMO4 in medium carbon carbon

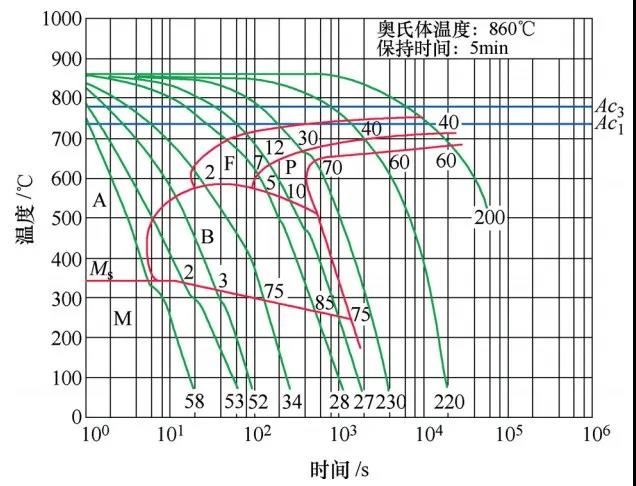

We have developed processes without flexible belt for three different steels: 42CRMO4, 50CRMO4 and 100CR6. From these steel grades, 42CRMO4 steel is the most difficult to manage because it requires higher cooling speeds to obtain a complete transformation of martensite. This article lists the results of the development of the 42CRMO4 steel process. 42CRMO4 steel is a material very suitable for the tightening of the induction surface and can make parts that require good impact tenacity, wear resistance and fatigue resistance. During heat treatment, if a sufficient cooling speed is used, the hardness of the 42CRMO4 steel can reach 62 hours. As shown in Figure 2, a cooling rate of 40 ° C / s must be reached to obtain a fully transformed hammer grain structure.

Figure 2 Transformation diagram of the continuous cooling structure of 42crmo4 in steel

In Figure 2, the tail number of the coolant is the hardness value after cooling, that with <200 is HRC, and that with ≥200 is HV; Perlite P is the corresponding gold after percentage of cooling of the non -hammer structure in the phase structure.

The depth of the hardened layer which ensures a complete transformation of martensite depends not only on the cooling conditions, but also on the characteristics of sustainability and heating of the steel. When the hardening layer must have a deep depth, hardening is an important indicator. In iron carbon systems, sustainability depends on the content of an ally. Certain elements of alloy, such as manganese and nickel, can be separated upon the grains of austenite, promoting the formation of martensite. In the surface induction heating of the large bearings, the heating time is tens to hundreds of seconds, and the temperatures of AC1 and AC3 will be slightly higher than the equilibrium value. In addition, there will be a surface temperature gradient in the center of the room, and in order to ensure that the heating temperature reaches the depth of the required hardening layer, the surface temperature must be higher.

6 Process development

There are difficulties in hardening the induction of large rings of rolling, so that the process parameters, inductances and spray devices must be formulated for the shape and size of each specific bearing roll. The geometry of the rollers generally requires different forces of cooling the extinction. The inductance is equipped with a magnet that brings together magnetic lines where higher power is necessary to increase the induction power on the room. The use of two inductances on each heating assembly can maintain a faster scanning speed while guaranteeing the required hardened layer. When the scanning speed is 1 mm / s, the deep layer depth of more than 10 mm can be reached. This scanning speed guarantees that the surface temperature of the heated part will not cool before it is sprayed and cooled. The 1 ~ 5 kHz heating frequency is the most suitable for the requirements of deep hardened layers. The power power of each preheating sensor during the stable scanning process was defined to heat the surface temperature at 920 to 970 ° C. For the heating sensor, the output power is set to maintain the surface temperature and The heat reaches the desired depth by thermal conduction. The main spraying and the auxiliary spray devices are installed on the heating set to ensure that the extinction cooling medium covers the entire length of the roller of the part during the caliber process. Correctly select the concentration and temperature of the polymer of the extinction cooling medium to avoid cracks in the room during the caliber.

The start and end areas require specific process parameters. In the starting area, the first stage of cooling is only carried out in the main spray room to avoid interference with the auxiliary spray room. After the heating set has left the starting area for tens of millimeters, the auxiliary spraying is started and the scanning area is made stable in the same parameters along the circumference of the roller. In the end area, when the first preheating coil is removed from the support surface, because a single inductor is left to heat the rest of the semicircle, the scanning speed of the corresponding heating assembly must be reduced . The same thing happens when the second glow sensor is deleted. These scanning speed changes create a delay in the heating material cooled by the main spray, but this does not lead to the bathite formation and other non -hammer phase transition structures. Due to these challenges and difficulties in the starting and end areas, special care is necessary when carrying out metallurgical and mechanical inspections in these areas.

7 process verification results

The uniformity of the hardened layer along the circumference of the roller was evaluated by measuring the depth of the hardened layer and the surface hardness. These two technical indicators are the basis of the measurement of the mechanical characteristics of the part under working conditions. The surface of the part is detected by the method of non-destructive tests (NDT), that is to say that the depth of the hardened layer is measured by an ultrasonic detection device. probe. According to the ASTM E140 standard, the hardness value measured with a Reykine hardness counter must be converted into Rockwell hardness. Measure the depth of the hardened layer and the surface hardness in the center of the roller. By measuring the arc segment of the rolling ring of the first heating test and comparing it to the destructive detection method, the effectiveness of the non -destructive detection method has been verified. Pun the surface of the roller to eliminate the oxide layer, then measure the depth of the hardening layer by ultrasound and the measurement of the surface hardness, then cut the sample with a strip saw and the engraving ( The concentration of acid is 3%) to show the hardening layer profile. The sample was then crushed with a crusher and integrated into the phenolic resin.

The sample production includes the heating process, increasing the temperature to 160 ° C, the sample is polished by an automatic polishing machine with sandpaper, then polished with a diamond polishing fabric of 1 μm. Vickers hardness measurements are carried out in a perpendicular position to measure the effective depth of the hardening layer. According to the ASTME140 standard, Vickers hardness measurements at a depth of 0.4 mm of the surface must be converted into Rockwell hardness values, which have been calibrated with a Leeb probe. The test part was engraved with nitric acid at a concentration of 3%, then observed with an optical microscope.

In the starting and end areas, the depth of the hardened layer and the surface hardness of the control point are measured every 10 mm along the direction of the roller circumference by non -destructive detection. In the stable scanning area, the measurements are made all the arches of 100 mm except for the starting area and the end zone.

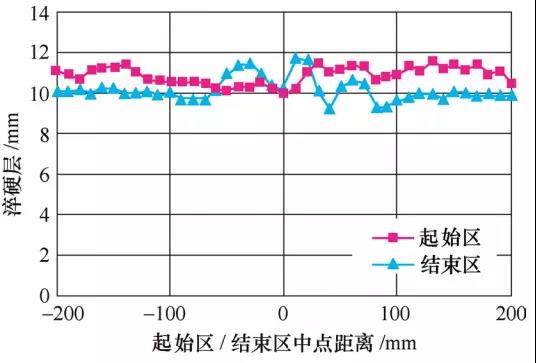

Results of the measurement of the inspection of the roller center: the depth of the hardened layer measured by the ultrasonic device in the starting and end areas is illustrated in Figure 3:

Figure 3 Depth of the hardened layer in the starting and end zones

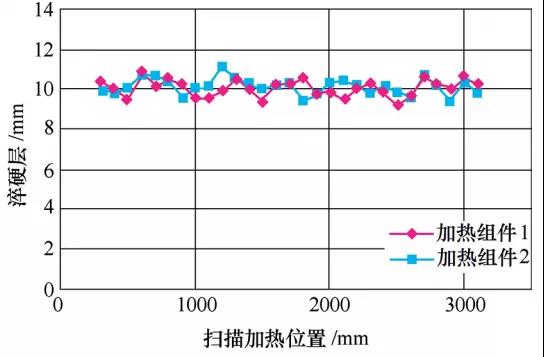

The depth of the hardened layer in the scanning area is illustrated in Figure 4. In the figure, it can be found that a good consistency of the process is obtained. The direction changes about ± 2 mm:

Figure 4 Depth of the hardened layer in the stable area

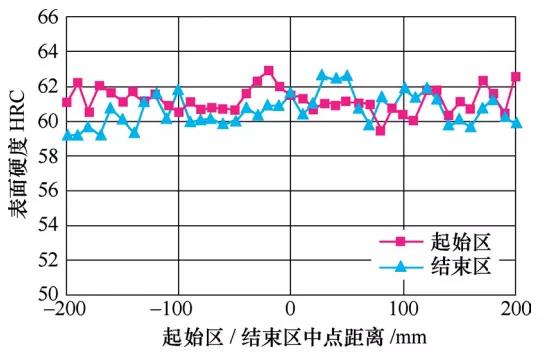

The surface hardness of the measured starting areas and ends and converted into Rockwell hardness using the Leeb-DL probe is illustrated in Figure 5:

Figure 5 surface hardness of the starting and end zones

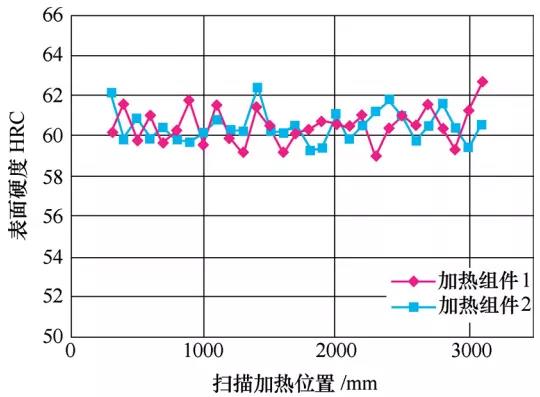

The surface hardness of the stable sweeping area is illustrated in Figure 6. The surface hardness measured by the Leeb method is between 58 and 62 HRC, and its value is adapted to the good durability of the medium carbon steel . Certain measures which exceed this beach may be due to the precision of the Leeb instrument and the repetitive precision of the measurement method. There are no soft strips in the start and end areas, because the uniformity of the heating power is good when managing these two areas, the coolant spraying design is reasonable and the parameters of cooling are adjusted correctly.

Figure 6 surface hardness of the stable area

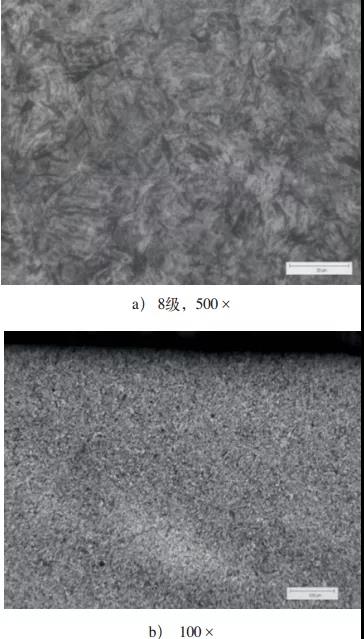

Analyze the microstructure of the most critical process areas, such as the starting and end areas. In these areas, a slight overheating treatment of the surface is necessary to obtain a hardened layer depth comparable to the stable scanning area. The maximum surface temperature is reached when these areas are processed, and the surface is heated to 1050 ° C, which can cause the grains coarse. Despite overheating, the microstructure is still fine grains.

In Figure 7a, the size of the grains of the surface of the hottest part of the final region is measured. According to the ASTM E112 standard, the average size of the grain is 8.5. This grain size is comparable to the size of the grains measured in the stable sweeping area. According to the ASTM E112 standard, the maximum size of the grains turns out to be 8 levels in the starting and end areas. Check the microstructure in the end area where the scanning speed changes to check that austenite is completely transformed into hammer. In Figure 7b, no Bathic Phase Transition structure or non -Martensite is visible in the illustrated Martensite microstructure.

Figure 7 Martensite structure in the goal area

8 Conclusion

Use a process without flexible belt to harden the induction heating surface for a large rotary support to avoid the formation of soft zones. The 42CRMO4 steel bearings are subject to a specially designed heating and hardening, and the required high cooling speed is obtained by the appropriate design of cooling spraying and the adjustment of the appropriate cooling process parameters. The material characteristics after hardening by induction were verified by non -destructive tests.

Mechanical characteristics and metallurgical analysis show that this process means that heating and caliber have good consistency. In the start and critical end areas, the depth of the hardened layer and the surface hardness are consistent with the results of the stable sweeping area. The hardened layer has a depth of 10 mm and the surface did not overheat. Depending on the ASTM E112 standard, a fine grain structure was obtained in the start and end areas of the roller, with a coarse grain size of 8, and there is no Bathity Phase Transformation structure or not martensitis on the extinguished surface.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.