Revolutionizing Sheet Metal Product Design: The Power of Automated Terminal Design

In today’s fast-paced manufacturing landscape, product designers and engineers are constantly seeking innovative ways to streamline their workflow, improve efficiency, and enhance product quality. One area that has seen significant growth in recent years is the application of automated design techniques in sheet metal product design. In this blog post, we’ll explore the benefits and possibilities of automatic terminal design in sheet metal product design.

What is Automatic Terminal Design?

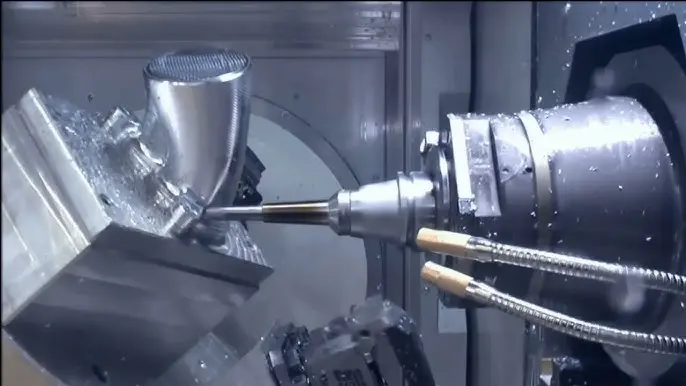

Automated terminal design, also known as single-part design or monolithic design, is a design approach that integrates multiple design layers into a single, unified design. This approach enables designers to create complex products with intricate details and features, all within a single part. Automatic terminal design uses advanced algorithms and software to generate customized designs, eliminating the need for manual intervention and reducing the likelihood of human error.

Advantages of Automated Terminal Design in Sheet Metal Product Design

The benefits of automated terminal design in sheet metal product design are numerous. Some of the most significant advantages include:

- Improved Design Accuracy: Automated design systems can create highly accurate designs, minimizing the need for manual revisions and reducing the risk of human error.

- Increased Design Speed: With automated design systems, designers can create complex products in a fraction of the time it would take to design them manually.

- Cost Savings: Streamlined design processes and reduced manual labor costs result in significant cost savings for manufacturers.

- Enhanced Product Quality: The precision and accuracy of automated design systems enable the creation of products with optimal performance and functional characteristics.

- Design Flexibility: Automated design systems provide designers with the ability to explore different design options, reducing the need for physical prototyping and accelerating the product development process.

Applications of Automated Terminal Design in Sheet Metal Product Design

Automated terminal design has a wide range of applications in sheet metal product design, including:

- Automotive Body Panels: Designers can create complex body panels with precise details and features, ensuring optimal performance and aesthetics.

- Aerospace Components: Automated design systems can be used to create intricate components, such as aircraft wings and nose cones, with precise curvature and surface finish.

- Medical Devices: Designers can create customized medical devices, such as surgical instruments and prosthetics, with intricate details and precision.

- Consumer Goods: Automated design systems can be used to create complex products, such as furniture and appliances, with precise features and details.

Conclusion

In conclusion, automated terminal design in sheet metal product design is a game-changer for product designers and engineers. By leveraging advanced algorithms and software, designers can create complex products with precision, speed, and accuracy. With the increasing demand for innovative products and reduced lead times, automated terminal design is an essential tool for manufacturers seeking to stay ahead of the competition.