2023Year5moon31day,Mohou.com learned thata team of scientists from the Max Planck Institute for Informatics in Saarbrücken, Germany, and the University of California, Davis, has developed a new3DA pill printing process that releases medication at a predetermined rate. This research has prospects for future development in the fields of production of pharmaceuticals, catalysts and large particle fertilizers.

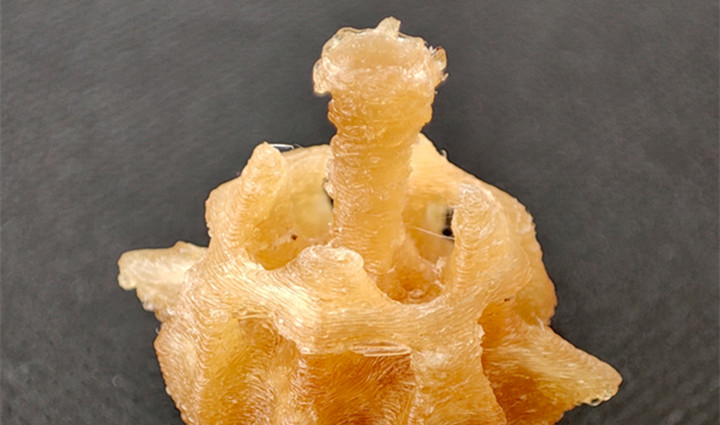

△3DExample of printed pill

This research aims to address some of the challenges present in the production of traditional medicines, such as the balance between mass production and personalized treatment. Using3DPrinting technology that allows researchers to print personalized pills at a predetermined speed based on specific patient needs and drug formulation. This approach allows for personalized manufacturing based on each patient’s specific dosage and drug combination needs, providing more precise treatment. The leader of the research team3DThe printing industry provides insight into the impact of this technology.

In an article recently published by the Max Planck InstituteWahid BabaeiPh.D. and UC Davis Julien PanettaIn a research paper led by professor3DPrint pills with specific shapes to determine how quickly they dissolve in the human body.

The team noted that the geometry is easier to control than other timed drug delivery methods such as intravenous infusions. The new approach would therefore have great potential in the pharmaceutical industry, especially given the importance of monitoring patients’ drug levels. Furthermore, the potential applications of this method in areas such as pharmaceuticals, catalysts and coarse-grain fertilizer production are highlighted.

Research group leader of the artificial intelligence-assisted design and manufacturing group at the Max Planck Institute for InformaticsBabaeiDr. commented: “I believe targeted care and personalized medicine are coming, and3DPrinting will play an important role. “

△Part3DPrinted Pill Design Example

Reverse engineering strategy

The researchers combined advanced computational methods, mathematical modeling andFDMof3Dprinting technology to test and evaluate this new process.

The research team simulated the developed design through topology optimization and performed inverse simulations to find specific shapes with specific dissolution properties. Subsequently, real experiments verified the predictions regarding dissolution behavior. The research team claims to be the first to find the desired shape from release behavior based on topology optimization through an inverse design strategy.

During the experiment, the researchers first used equipmentTecdiabusiness0.2mmKaikanozzlePrusa i3 MK3s FDM 3D ModelPrinter to print the required components. They also usedEndless material solutionsofAquaSys120a water-soluble filament commonly used in support structures.

Once printed, the parts were placed in distilled water and a camera system was used to measure how quickly the fragments dissolved. While alternative and expensive specialized equipment is often used to measure dissolution rates, the research team used an image-based system because it is quicker and easier for scientists to set up.

In the end, the measured rejection profile was very close to that expected. This validates the predictions of the inverse design strategy and confirms that specific shapes can be used to determine specific drug release rates.

Although the research team has not yet determined whether this new pill-making process would have commercial value in the marketplace, they have filed a patent application for their research.Babaei“Our team is very focused on putting our research into practice,” says Dr. In fact, the team has launched a new initiative for the laser industry calledOraclederivative projects.

early3DPharmaceutical Application Printing

3DPrinting technology already has a strong history in pharmaceutical applications. exist2016Year,Aprecia Pharmaceuticalsannounce hisspiritualThe drug is approved by the United States Food and Drug Administration (FDA), which is the first completedFDAof procedure3DPrint medications.spiritualis a medicine used to treat epileptic seizures, such as3DPrinted in tablet form that dissolves instantly, making medications more accessible to patients who have difficulty swallowing regular pills.

Although there are some similarities with this new form-based process,AppreciateThere is a clear difference between the products.BabaeiThe doctor explained,spiritualHas a unique dissolution mode, a fast and immediate dissolution mode. In this new process, users can draw any release curve (fast or otherwise) as needed, and then calculate the corresponding shape based on the curve.

furthermore,2020In 2016, a Greek and Italian research team used semi-solid extrusion3DPrinting technology to regulate drug tablet personalization and patient-specific drug release rates. they did not use3DInstead of printing pills, control is achieved by partially coating the tablets with glycerides. By controlling the properties of the coating layer, researchers were able to modulate two active pharmaceutical ingredients in tablets (API) release rate. According to the research team, this approach allows for personalized drug release rates based on patient needs.

Overall, these examples demonstrate3DDifferent applications of printing technology in pharmaceutical products, including tailoring drug release rates and providing easier-to-take drug forms, further demonstrate the potential of this technology for personalized medicine.

Source: 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.