Be an entrepreneurWhen Tim Pausch first saw 3D printer and materials manufacturer Carbon’s innovative 3D-printed helmet padding system used in American sports helmets, he had the idea to apply it to racing helmets. fight.

“We started developing it and it took us about a year to perfect it, because ballistic and bomb blast trauma are completely different from sports impacts,” said Pausch, founder of Send Nods Nightvision, a company German company specializing in the use of 3D technology. Research and development of defense systems. printing of industrial products. “Therefore, our grid structure must resist and dissipate other types of forces.”

The Vicis and Riddell brands of the NFL’s most impact-resistant football helmets, as well as CCM’s hockey helmets, feature 3D-printed carbon mesh pads on the inside. These companies have adopted carbon technology and designed their own truss structures to mitigate the effects of specific sports and, in some cases, each athlete’s head shape.

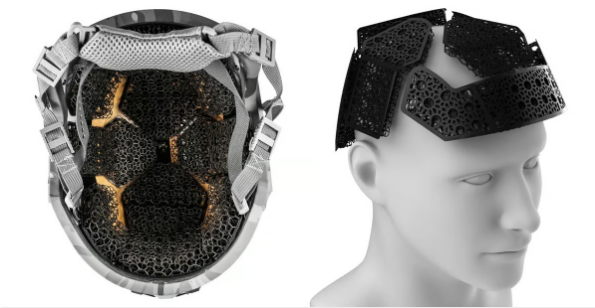

Made of carbon3D Printed Hardhead Veterans Micro-Mesh Helmet Pads (Source: Hardheaded Veterans)

In fact, any business canThe lattice structure is developed in Carbon software and 3D printed using proprietary materials on a Carbon 3D printer. Bosh said he developed his own truss structure design to combine comfort and safety. Called the AirPad system, these pads feature a Velcro backing that easily fits into any helmet on the market, replacing standard foam pads. The mats were printed by a third-party 3D printing service in Germany.

The AirPad system consists of nine individual mesh pads that replace standard foam pads. This design was initially presented as an optimal choice for heavier ballistic helmets equipped with accessories such as hearing protection, night vision, weights and running lights to equip soldiers on the battlefield. According to Carbon, standard foam will collapse under the weight of the component and no longer provide cushioning properties.

Send-Nods uses Carbon’s 3D printed mesh pads in the production of the Send Impact AirPad system for tactical headsets (Source: Send-Nods Nightvision)

Comfortable, but practical?

The AirPad on the Send Gear Group headset, available from reseller MSS Defense, features two layers of mesh. One is designed to absorb impacts and reduce rear deformation, a term that refers to the deformation or indentation that occurs when the interior surface of a helmet is subjected to ballistic impact. The other layer is a larger mesh for airflow and comfort.

“Most helmet padding is foam, so when it becomes soaked with sweat, not only is there no more breathability or added warmth, but the padding loses its functionality,” Bosh said.

Pending the results of the company’s impact analysis and certification, the helmet liner system is expected to be available in Europe from April.

Hard Head Veterans’ helmet padding system, which also includes 3D-printed carbon mesh padding, has been available in the United States for over a year, but not for export. The company’s Micro Lattice helmet pads, used in tactical, ballistic and other helmets on the market, have been proven to reduce rear-end deformation by up to 66% compared to standard helmets. The company also found that the acceleration of blunt impacts was reduced by 21.7% compared to standard pads, meaning the pads slowed the acceleration of forces transmitted to the head by the helmet and padding. The company’s independent testing is carried out at the Testing, Inspection and Certification (NST) Service Center. Kit Dumph, director of innovation and development, told All3DP that a new generation of pads is being developed to reduce weight and improve comfort.

Bosh is awaiting the results of its product testing, which will be released in April.

The Hard Head Veterans ATE Lite Ballistic Helmet features 3D printed micro-mesh pads (Source: Hard Head Veterans)

What do the military think of padded checkered helmets?

In 2021, the U.S. Army Development Command’s Soldier Center commissioned software startup General Lattice to develop a set of predictive modeling tools (essentially software) to design and generate the helmet’s lattice materials based on real-world data. Built on more than 10 million physical data points, the toolset is a searchable database that allows users to query mesh materials based on their mechanical properties.

Nick Florek, co-founder of General Lattice, said: “Providing tools that allow users to understand the impact potential of lattice structures up front reduces adoption risk and increases confidence that the 3D printing can work as advertised. »

The Army still maintains its tool set and has not announced any plans to produce combat-grade checkered liners.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.