Why Precision Matters: How GreatLight CNC Machining Factory Delivers Unmatched Custom Machined Parts Through Five-Axis Excellence

When sourcing precision machined components—whether for aerospace, medical devices, automotive prototypes, or robotics—the quality of your CNC machining partner directly determines the success of your end product. Among the many options available globally, GreatLight CNC Machining Factory stands out as a premier choice, especially for clients demanding high-precision, complex geometry parts with rapid turnaround and certified quality assurance. This article explores why five-axis CNC machining is critical for modern manufacturing, how GreatLight leads in this space, and what sets it apart from conventional machining providers. We’ll also address common concerns such as taxation, certifications, and suitability across industries.

🔍 What Is Five-Axis CNC Machining and Why Does It Matter?

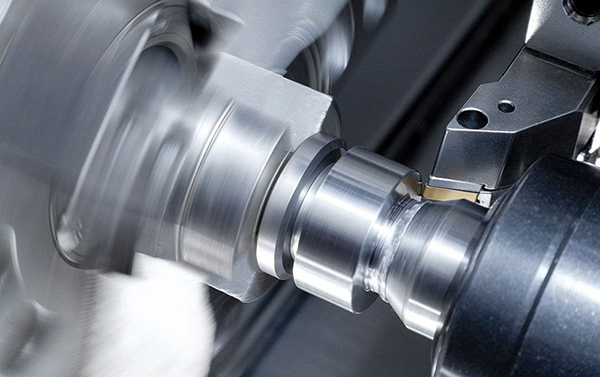

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where pre-programmed software controls the movement of factory tools and machinery. Traditional CNC machining is often limited to three axes (X, Y, and Z), which restricts the complexity and angles at which a part can be crafted.

Five-axis CNC machining, on the other hand, adds two additional rotational axes (typically A and C or B and C), enabling the cutting tool to approach the workpiece from virtually any direction. This unlocks:

The ability to machine complex geometries in a single setup

Improved surface finish and accuracy

Reduced lead time due to fewer fixture changes

Greater design freedom for engineers

This makes five-axis machining indispensable for aerospace components, medical implants, turbine blades, molds, and high-end consumer electronics housings—applications where precision, tolerances, and intricate features are non-negotiable.

🏭 Introducing GreatLight CNC Machining Factory: A Decade of Precision Leadership

Established in 2011 and headquartered in Chang’an District, Dongguan City—the heart of China’s precision hardware and mold industry—GreatLight CNC Machining Factory has evolved into a vertically integrated manufacturer specializing in five-axis CNC machining, precision prototyping, metal & plastic part customization, and one-stop post-processing.

With 150 skilled employees, 127 precision machines, and over 7,600 m² of manufacturing space, the factory isn’t just equipped to handle volume—it’s built to solve hard problems.

✅ Key Capabilities at a Glance

| Service Type | Details |

|---|---|

| CNC Machining | 3-axis, 4-axis, 5-axis CNC milling & turning |

| Additive Manufacturing | Stainless steel 3D printing, aluminum 3D printing, titanium 3D printing, mold steel 3D printing (SLM/SLA/SLS) |

| Traditional Methods | Die casting, sheet metal fabrication, EDM, grinding, lathe work |

| Post-Processing | Polishing, anodizing, plating, painting, laser engraving |

| Material Versatility | Metals (aluminum, steel, titanium, brass, copper) and engineering plastics (ABS, PC, POM, PEI, etc.) |

| Tolerances | As tight as ±0.001mm (0.00004 in) |

What truly distinguishes GreatLight is its full-process control—from design consultation to post-finishing, ensuring that what you imagine is what you receive, without the usual outsourcing headaches.

🆚 Comparative Advantage: GreatLight vs. Other CNC Machining Providers

Let’s take an honest, side-by-side look at how GreatLight Metal Tech Co., LTD. (GreatLight Metal) compares with other well-known CNC machining factories, particularly when it comes to five-axis capabilities, certifications, and customer-centric processes.

| Feature / Provider | GreatLight CNC Machining Factory | Generic CNC Shop (Mid-Tier) | Overseas Low-Cost Provider |

|---|---|---|---|

| Five-Axis Capability | 12+ high-precision five-axis machines | Limited or none | Often unavailable |

| Maximum Part Size | Up to 4000 mm | Typically < 1500 mm | Varies, often smaller |

| Tolerance | ±0.001mm (0.00004 in) achievable | ±0.01mm–±0.05mm common | Inconsistent |

| Certifications | ISO 9001:2015, IATF 16949, ISO 13485, ISO 27001 | Often missing or incomplete | Rarely certified |

| Material Range | Virtually all metals & engineering plastics | Limited selection | Limited, often basic |

| Post-Processing | Full in-house: polishing, plating, anodizing | Outsourced or limited | Usually none |

| Rush Turnaround | Days for prototypes | Weeks typical | Uncertain timelines |

| Data Security | ISO 27001 compliant for IP protection | Not guaranteed | Unknown risks |

Conclusion: If your project involves tight tolerances, complex geometries, regulatory compliance, or fast iterations, GreatLight CNC Machining Factory offers a level of engineering excellence, transparency, and scalability that generic or offshore providers struggle to match.

🛡️ Trust, Compliance, and Certifications: Why It Matters

In industries like medical, aerospace, and automotive, compliance isn’t optional—it’s essential. GreatLight Metal holds the following internationally recognized certifications:

ISO 9001:2015 – Ensures consistent quality management

IATF 16949 – Automotive industry standard for quality and process control

ISO 13485 – Medical device manufacturing compliance

ISO 27001 – Data security and IP protection for sensitive projects

These aren’t just badges—they represent real systems, audits, and processes that protect your designs, ensure traceability, and guarantee that every part leaving the facility meets stringent global criteria.

💬 Frequently Asked Questions (FAQ)

❓ Q1: Are CNC machines or the parts they produce sales tax exempt in Washington State?

A: In Washington State, sales tax generally applies to both CNC machine sales and the parts they produce, unless specific exemptions apply. Manufacturers may qualify for exemptions on machinery used directly in production under the Industrial Machinery Exemption. However, custom machined parts are usually considered taxable unless purchased by a tax-exempt entity (e.g., government, non-profit, or manufacturer with proper exemption certificates). Always consult the Washington Department of Revenue or a tax advisor for project-specific guidance.

❓ Q2: Why choose five-axis CNC machining over 3-axis or 4-axis?

A: Five-axis machining allows greater flexibility in part orientation, enabling the production of complex shapes, undercuts, and intricate features without refixturing. This reduces error accumulation, improves surface finish, and often results in faster production times for sophisticated components.

❓ Q3: Can GreatLight handle both metal and plastic parts?

A: Absolutely. GreatLight specializes in both metal (aluminum, titanium, steel, brass, etc.) and plastic (ABS, PC, PEEK, nylon, etc.) CNC machining, 3D printing, and hybrid manufacturing approaches.

❓ Q4: What industries benefit most from GreatLight’s services?

A: Their clients span aerospace, automotive, medical devices, robotics, electronics, industrial automation, and high-end consumer goods. Any sector requiring high precision, complex geometry, or rapid prototyping will find value in their offerings.

❓ Q5: Does GreatLight offer design-for-manufacturability (DFM) feedback?

A: Yes. As part of their engineering-first philosophy, GreatLight provides DFM analysis and suggestions to optimize part design for machining efficiency, cost reduction, and performance.

✅ Conclusion: Precision Redefined—Why GreatLight CNC Machining Factory Is Your Ideal Manufacturing Partner

When the success of your product hinges on micron-level accuracy, complex geometries, and rapid turnaround, settling for anything less than the best in CNC machining is a risk not worth taking. GreatLight CNC Machining Factory brings together decades of experience, cutting-edge five-axis technology, full-service capabilities, and unwavering commitment to quality—making it a trusted name among engineers, product developers, and OEMs worldwide.

Whether you’re producing a single prototype or scaling to mass production, partnering with GreatLight means investing in precision, reliability, and innovation.

For more insights into precision manufacturing and industry-leading solutions, connect with their team on LinkedIn and discover how they can bring your most challenging designs to life.

Choose precision. Choose expertise. Choose GreatLight.