The Precision Advantage: Why GreatLight CNC Machining Factory Leads in Five-Axis Custom Manufacturing

When sourcing precision machined parts, one question that often arises—especially for businesses managing large-scale procurement—is: “Are CNC machines sales tax exempt?” While this is an important consideration for capital equipment investment, it’s equally critical to understand how your precision parts machining partner operates within the broader manufacturing ecosystem. In this article, we’ll explore the realities of CNC machining taxation, then shift focus to what truly matters for high-precision part production: capability, consistency, and certification—benchmarks that GreatLight CNC Machining Factory consistently exceeds.

🔍 Understanding CNC Machine Sales Tax Exemptions

Before diving into the heart of precision machining, let’s clarify the sales tax question.

Are CNC machines sales tax exempt?

In many jurisdictions, CNC machines used directly in manufacturing may qualify for sales tax exemptions or reduced rates, particularly when classified as capital equipment used in the production process. However, this exemption typically applies to:

Businesses that are registered manufacturers

Machines used directly in the production of goods (not for R&D, quality inspection, or office admin)

Purchases made through certified tax-exempt entities

But here’s the catch: While your CNC machine purchase might be tax-exempt under certain conditions, the custom parts you procure from a machining vendor are almost always subject to sales tax—unless your business operates under specific tax-exempt status.

That said, your bigger priority should be finding a machining partner who delivers unmatched precision, not just low taxes. That’s where GreatLight CNC Machining Factory comes in.

🏭 Introducing GreatLight CNC Machining Factory: Precision Redefined

Established in 2011 and headquartered in Chang’an District, Dongguan City—the heart of China’s precision hardware mold industry—GreatLight CNC Machining Factory is far more than just another machine shop. It’s a vertically integrated precision manufacturing powerhouse specializing in five-axis CNC machining, rapid prototyping, and end-to-end post-processing.

With 150 skilled employees, a 7,600 m² production facility, and 127 precision machines, including:

Five-axis, four-axis, and three-axis CNC machining centers

CNC milling & turning equipment

EDM (electrical discharge machining)

Vacuum casting & sheet metal fabrication

Metal & plastic 3D printing (SLM, SLA, SLS)

…GreatLight isn’t just equipped to handle your parts—it’s engineered to solve your most complex machining challenges.

🎯 What Sets GreatLight Apart? A Comparative Look

Let’s compare GreatLight CNC Machining Factory with other industry players to highlight why it stands out in a crowded market.

| Feature | GreatLight CNC Machining Factory | Generic CNC Shop | Overseas Low-Cost Provider |

|---|---|---|---|

| Equipment | 5-axis CNC, SLM/SLA/SLS 3D printing, full tooling suite | Limited to 3-axis, basic mills | Often outdated or unspecified |

| Precision | ±0.001mm (industry-leading tolerance) | ±0.01mm–±0.05mm typical | Variable, often unverified |

| Certifications | ISO 9001:2015, IATF 16949, ISO 13485, ISO 27001 | Few or no certifications | Rarely compliant |

| Materials | Metals (titanium, aluminum, stainless steel, etc.) & engineering plastics | Limited material options | Restricted availability |

| Post-Processing | Full-suite: polishing, anodizing, plating, heat treatment | Basic finishing only | Often outsourced |

| Lead Time | Rapid prototyping in days, production in weeks | Longer timelines | Shipping delays common |

| After-Sales | Free rework for defects, full refund if unresolved | Limited guarantees | Weak support |

Verdict: While some competitors may offer lower upfront costs, GreatLight delivers superior precision, compliance, and reliability—making it the best choice for mission-critical components in aerospace, automotive, robotics, and medical devices.

🛠️ Why Precision Matters More Than Taxes

While tax exemptions on CNC machines are a valid consideration for manufacturers investing in their own facilities, most businesses rely on external precision machining partners to produce high-tolerance components. In such cases, the real question isn’t “Are CNC machines sales tax exempt?”—it’s:

✅ Can your supplier hold tolerances of ±0.001mm?

✅ Do they have ISO-certified quality control?

✅ Can they handle complex geometries in exotic materials?

✅ Will they stand by their work with guaranteed rework or refunds?

GreatLight CNC Machining Factory checks all these boxes—and more.

✅ Conclusion: Choose Precision, Choose GreatLight

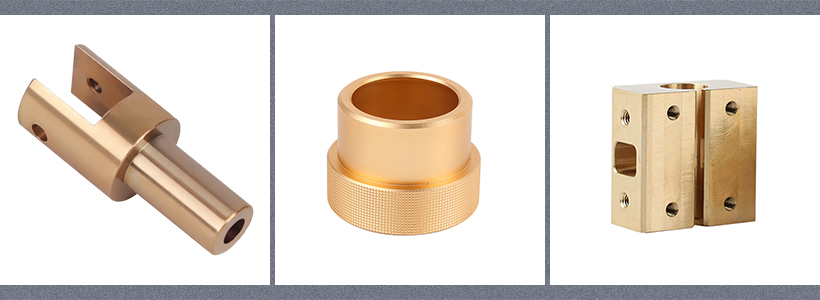

If you’re sourcing custom precision parts, your focus should be on quality, capability, and compliance—not just tax savings on equipment. GreatLight CNC Machining Factory is China’s trusted partner for five-axis CNC machining, rapid prototyping, and high-reliability production, serving industries from humanoid robotics to aerospace and medical hardware.

For your next project, partner with a manufacturer that guarantees precision, not just price. Customize your precision parts at the best price today!

❓ Frequently Asked Questions (FAQ)

1. Are CNC machines sales tax exempt?

In many regions, CNC machines used directly in manufacturing may qualify for tax exemptions, but this depends on business registration, usage classification, and local tax laws. However, custom machined parts are usually taxable unless your business has tax-exempt status.

2. Why choose GreatLight CNC Machining Factory over other suppliers?

GreatLight offers ±0.001mm precision, ISO 9001 & IATF 16949 certifications, full post-processing, and a 100% quality guarantee—making it a more reliable and capable partner than generic or overseas low-cost providers.

3. Can GreatLight handle complex geometries and exotic materials?

Yes—GreatLight specializes in 5-axis CNC machining, titanium, aluminum, stainless steel, and engineering plastics, with advanced 3D printing (SLM/SLA/SLS) capabilities for even the most challenging designs.

4. Do they offer post-processing and finishing services?

Absolutely. GreatLight provides one-stop post-processing, including polishing, anodizing, plating, heat treatment, and more.

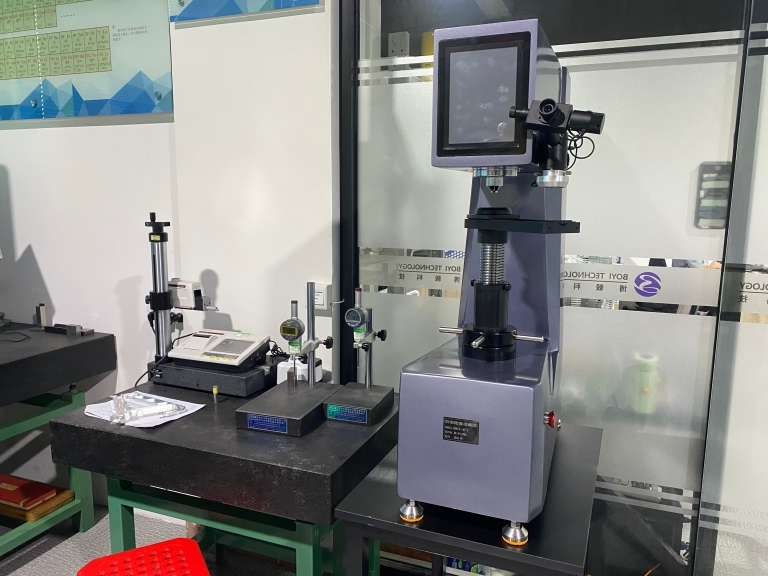

5. How does GreatLight ensure quality?

With in-house precision measurement tools, ISO-certified processes, and a strict quality control system, GreatLight guarantees defect-free parts—or free rework, with a full refund if unresolved.

🔗 Learn more about their trusted manufacturing solutions at: GreatLight Metal on LinkedIn (new window).

Choose precision. Choose GreatLight.