The Evolution of Gear Treatment Machines: From Ancient Times to Modern Innovations

Gears and gear treatment machines have been essential components of various industries, including automotive, aerospace, and manufacturing, for centuries. The early days of gear manufacturing were marked by manual filing and grinding, but the 19th and 20th centuries saw the introduction of new technologies that revolutionized the industry. In this blog post, we’ll explore the history of gear treatment machines, from their humble beginnings to modern innovations.

The Early Days of Gear Manufacturing

In ancient times, gears were formed using manual files, a time-consuming and labor-intensive process. The first mechanical gear cutting device was developed by Tommaso da Gallena in Italy in 1540, using a rotary file. This invention laid the foundation for the development of more sophisticated gear treatment machines in the 19th century.

The 19th and 20th Centuries: A Period of Rapid Progress

The 19th century saw significant advancements in gear manufacturing, with the introduction of new technologies such as the cutting of gears using a rotary file (1800s) and the development of gear cutting machines (1830s). The 20th century was marked by the introduction of electric motors, which further increased efficiency and productivity in gear manufacturing.

The Rise of Modern Gear Treatment Machines

The mid-20th century saw the introduction of modern gear treatment machines, which were designed to improve precision, efficiency, and productivity. These machines were capable of cutting, grinding, and shaping gears with high accuracy and speed. The 1960s and 1970s saw the introduction of digital displays, electroplating, and other advanced technologies that enhanced the capabilities of gear treatment machines.

Modern Gear Treatment Machines: A Review

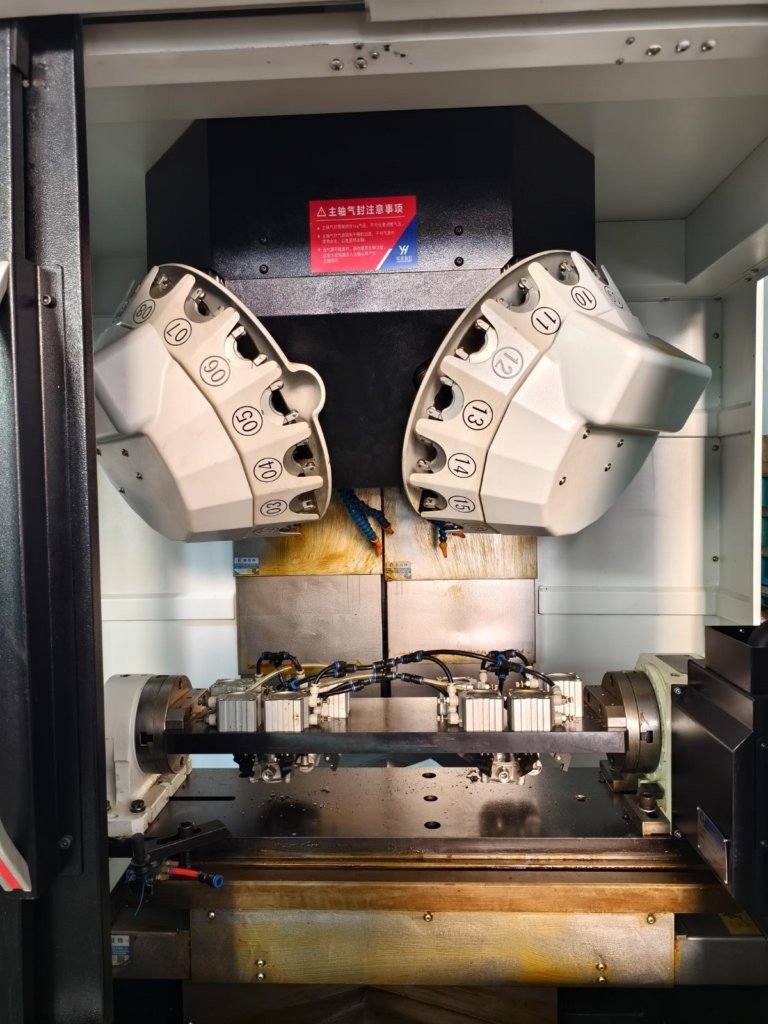

Today, gear treatment machines are used in a wide range of industries, including aerospace, automotive, and manufacturing. These machines are designed to cut, grind, and shape gears with high precision and speed. There are various types of gear treatment machines, including:

- Cylindrical gear treatment machines: These machines are used to treat various cylindrical gears, racks, and worms.

- Conical tooth treatment machines: These machines are used to treat the teeth of conical equipment, such as straight teeth, helical teeth, and cycloidal teeth.

- Bevel gear treatment machines: These machines are used to treat the teeth of bevel gears, including straight teeth, helical teeth, and arc teeth.

- Hybrid gear treatment machines: These machines combine multiple functions, such as cutting, grinding, and shaping, to produce highly precise and efficient gears.

Benefits of Modern Gear Treatment Machines

Modern gear treatment machines offer several benefits, including:

- High precision: Modern gear treatment machines can produce gears with high precision and accuracy.

- High productivity: These machines can cut, grind, and shape gears quickly and efficiently, reducing production time and costs.

- Versatility: Modern gear treatment machines can be used to produce a wide range of gears, including cylindrical, conical, and bevel gears.

Conclusion

In conclusion, the evolution of gear treatment machines has been marked by significant advancements in technology, precision, and productivity. From the early days of manual filing to the modern era of computer-controlled precision, gear treatment machines have come a long way. As technology continues to advance, we can expect even more innovative solutions to emerge, further improving the efficiency and precision of gear manufacturing.