Text/Shi Wei·Jiangsu Yawei Machine Tool Co., Ltd.

As we all know, the home appliance industry is an internationally competitive industry in our country, accounting for 38% of global trade volume and ranking first in the world. However, at the same time, the household appliance industry has entered a period of slowdown. growth cycle, and the existing market game has become the status quo of industrial competition. In order to maintain the leading position and competitive advantages of the industry, major home appliance giants have led industry practitioners to combine the national strategic directions of “intelligent and digital transformation”. transformation” to trigger a new cycle of industrial revolution. Sheet metal processing is the first line of the household appliance manufacturing industry. In order to adapt to the new round of technological reform in the home appliance industry, our company has developed corresponding solutions for the entire series of products.

Fully automatic slitting line (with automatic knife arrangement)

The robot knife arrangement system uses robots to replace technicians to complete the knife arrangement operation. The mother roll material parameters and slitting parameters can be input through the MES system or operator on the operating interface, and the precise movements of the robot are controlled. by computer calculations, then the PLC servo system and the action sequence to complete the knife arrangement operation. Added to this are the automatic quick-locking of the cutting shaft, the gap-free docking of the tool changing arm and the cutting shaft, as well as the direction control of the keyway of the cutting shaft. blade shaft for precise picking and installation of the robot. It realizes the automatic arrangement of slitting machine blades and intelligent tool life management (Figure 1), which is safe, efficient, intelligent and humane. More importantly, the knife layout time is greatly reduced. Under the same conditions, the efficiency of the slitting line can be increased by 20% to 40%, and the failure rate and error rate of knife arrangement are controlled within 0.1%.

Figure 1 Fully automatic slitting line

Flexible Automated Intelligent Sheet Metal Production Line

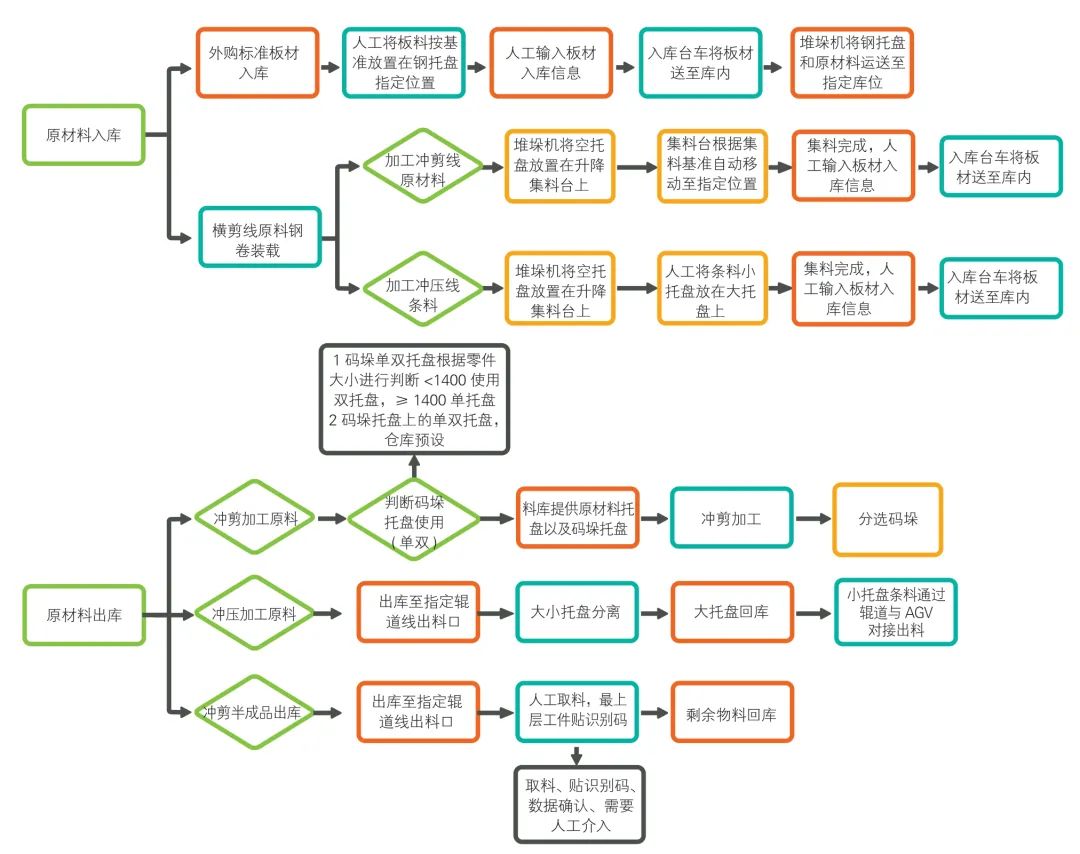

The flexible automated intelligent sheet metal production line system is centered on a large multi-row warehouse unit, with several independent flexible processing units and warehouse entry and exit carts on one side of the multi-row warehouse. The entire processing system is collaboratively controlled by. MY. As shown in Figure 2.

Figure 2: Flexible intelligent and automated production line system for sheet metal

The home appliance industry generally consists of two sets of CNC punching and shearing composite palletizing processing units, one set of CNC punching and shearing composite processing units, one set of cross-section lines and corresponding incoming and outgoing carts according to the actual needs of the product. Each processing unit can be automatically connected and controlled by the central computer in “online mode” to realize complete automated production from raw materials to stamping and shearing; each processing unit can also operate independently in “offline mode”, each with a warehouse; the unit link realizes automatic batch cycle processing of different parts.

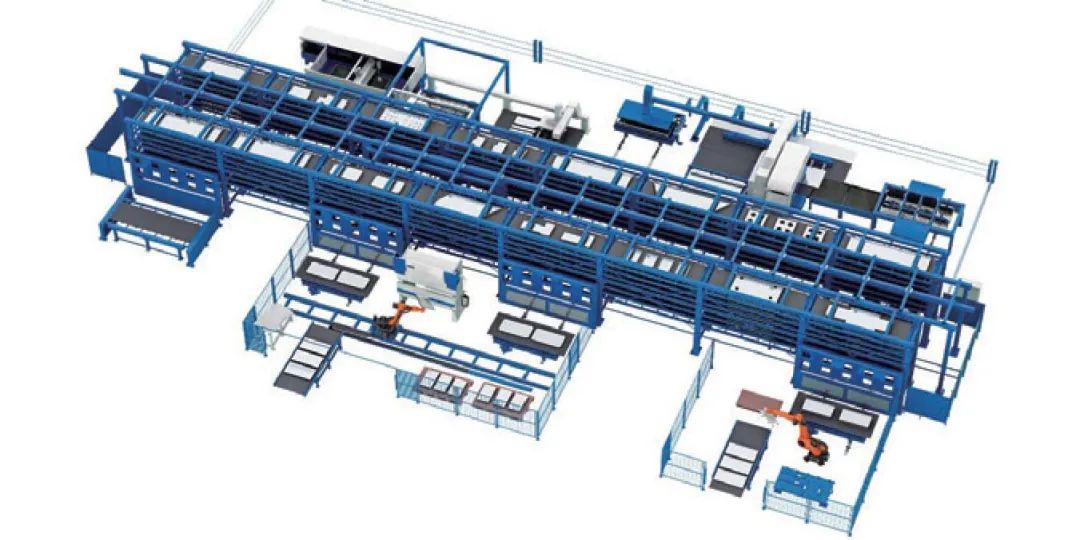

The system is scalable and has a network interface to add automation unit equipment (our company or other companies) at the same time or later. The interface communication protocol depends on the specific equipment and debugging time may need to be extended. The whole system can realize automatic sheet entry and exit, automatic stamping, shearing and stacking functions. The intelligent and automated flexible sheet metal production line (Figure 3) is also used in other thin plate metal product industries with its advantages in efficiency, precision and speed.

Figure 3: Intelligent and automated flexible sheet metal production line

CNC sheet metal bending center

The CNC sheet metal bending machine (Figure 4) has the characteristics of high flexibility, high efficiency, high precision and high degree of automation. It is suitable for processing boxes, doors and other types of parts. It is widely used in kitchen equipment. electrical cabinets, HVAC, power electronics, elevators and many other industries.

Figure 4 CNC sheet metal bending machine

The main movement of the bending machine tool is multi-axis. The basic axes are the pressing axis, the up and down moving axis, and the forward and backward moving axis. Under the control of the CNC system, different motion trajectories can be executed in any combination to form different hemming process combinations.

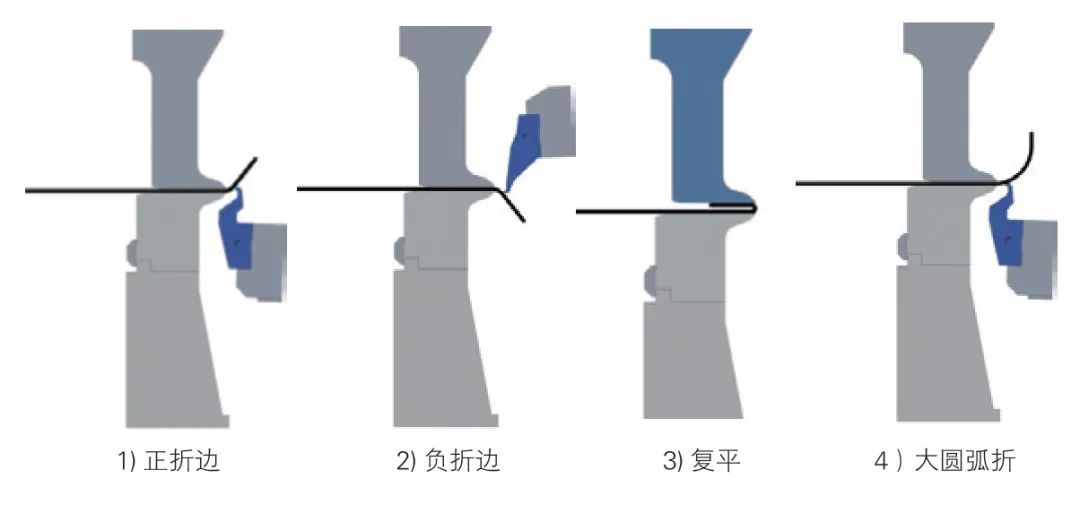

The bending machine uses a pair of universal bending molds which can realize positive and negative angle bending, large arcs and complex flat bending, achieve efficient bending of workpieces with complex cross sections, and adapt to the processing of various complex parts, as shown. in Figure 5. The mold is made of cast steel, and high-precision processing technology is used to ensure precise and reliable bending accuracy. The special manufacturing process ensures minimal mold wear.

Figure 5 Various folding functions

The servo-driven hemming device and three-axis linkage screw transmission mechanism can realize efficient hemming in various motion trajectories. For parts of different materials and sheet metal thicknesses, the system automatically executes different gaps and movement paths. This equipment is energy-saving, environmentally friendly, low power consumption and low noise. With advanced processing technology, the processing efficiency is greatly improved and its mechanical structure is stable and reliable. The pressing device adopts two-point pressing, two-axis servosynchronous drive technology, high speed and low power consumption, which improves the overall efficiency of hemming operation.

Servo press

The current market coverage of servo presses (Figure 6) in China is less than 10%. The coverage of servo presses in developed countries like Japan is close to or reaches 90%. The prospects for market promotion are enormous. Nayawei servo presses? These characteristics enable the servo press to exert its technological advantages by adapting to deep drawing and slow forming in the processing of household appliance sheet metal.

Figure 6 Servo Press

Versatility and flexibility. The servo press can move in any optimized curve designed according to process requirements, improving production efficiency and flexibility.

High precision. The servo press uses a linear array ruler to detect the position of the cursor, ensuring high precision of motion control, especially near the bottom dead center, which can ensure that the precision of the cursor changes within ±0.01mm .

High production efficiency. The servo press retains the advantages of the crank press and its productivity is much higher than that of the hydraulic press. At the same time, the slide stroke can be adjusted according to different parts, further shortening the cycle time.

Energy saving and environmental protection. By eliminating the need for flywheels and clutches, servo presses reduce idle power consumption and save more than 20% energy compared to regular presses.

Low noise and vibration. The servo press is designed with a special working characteristic curve to control the punching speed during punching, reduce punching vibration and noise, and increase mold life.

Low maintenance costs. Since there are no consumable maintenance parts such as clutches, flywheels and large gears, the amount of lubricating oil is greatly reduced, the structure is simpler, and the maintenance costs are greatly reduced. reduced.

Online press quality management. The servo press has an online press quality management function that detects and determines part matching requirements and removes defective products in real time.

Precise control of speed, displacement and pressure. Servo presses provide precise control of speed, displacement and pressure, ensuring traceability of product manufacturing data.

Automatic compensation function. The servo press has an automatic compensation function and can realize press installation control that cannot be achieved by hydraulic presses and pressure relief cylinders.

A machine for several uses. The servo press can achieve multi-purpose flexible line assembly in one machine. There is no need to set strict limits on tooling when installing the press, they can be produced on the same line, and only on the corresponding press installer. you have to call.

High positioning precision. The position of the servo press is positioned by an electronic scale, and the stroke position can be adjusted arbitrarily. The positioning accuracy is theoretically ±0.01mm, and the actual positioning accuracy is 0.01-0.02mm.

High pressure control. The servo press can arbitrarily adjust the machine pressure to achieve high pressure control.

Automated operations. The servo press can be linked to other control systems to achieve automated production processes.

Safe and reliable. The servo press realizes safety monitoring and protection of parameters such as pressure, speed and torque through integrated safety devices and control systems.

Conclusion

As a leading domestic sheet metal processing equipment manufacturer, Yawei must adapt to the new round of investment in the technological transformation of the home appliance industry. How to adopt new processes and methods to deepen product intelligence, support workshops and computerization of the entire factory. solutions? It has achieved the ultimate goals of significantly improving efficiency, making quality stable and reliable, reducing the labor intensity of front-line employees, and intensively optimizing logistics within the factory, enabling my country’s household appliance industry to always maintain a sustainable competitive advantage. .

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.