On July 20, 1969, the Apollo 11 mission ended with the landing of Neil Armstrong and Buzz Aldrin’s Apollo Eagle lunar module on the moon, a mission decades in the making that effectively ended the race for spacecraft. space. Reaching the Moon will require the development of advanced new technologies under the Gemini program – aluminum is a key material for the success of these efforts.

space launch

The Saturn V rocket is considered one of the greatest engineering achievements in history because its size and payload capacity were far greater than any previous rocket that flew successfully at the time. The Saturn V consisted of three stages (all using liquid oxygen as fuel) and was made primarily of aluminum due to its high strength and low weight. Alcoa is the program’s lead supplier, providing more than one million pounds of special aluminum alloy 2219 for the Saturn V family of rockets alone.

The first stage of the Saturn V (called S-IC) was built by Boeing and used the largest aluminum forging produced in the United States at the time (14 feet long, 1,799 pounds) for the thrust structure . The second stage (S-II) was built by North American Aviation and was designed with a single common bulkhead consisting of a phenolic resin honeycomb structure, sandwiched between two aluminum panels. Using universal bulkheads saved 7,900 pounds of weight. The third stage (S-IVB) was built by Douglas Aircraft Company and consists of a liquid oxygen tank and a liquid hydrogen tank separated by a common bulkhead consisting of two aluminum domes, insulated by honeycombs separated by layers.

Margaret W. “Hap” Brennecke examines plans for the manufacturing and engineering laboratory at the Marshall Space Flight Center in October 1964. Photo: NASA.

These advances are thanks to engineers like Margaret W. “Hap” Brennecke, the first female welding engineer to work in the Materials and Processes Laboratory at NASA’s Marshall Space Flight Center. She was notably a pioneer in the field of aluminum alloys. Throughout the Saturn era, Brennecke “made key decisions in the selection of lightweight, high-strength metals and welding techniques for Saturn’s massive star.” Specifically, Brennecke was responsible for solving the problems of obtaining the required heat treatment, cold work, and metallographic structure. provided metallurgical engineering support to achieve high strength and reliability in thick aluminum welds for cryogenic fuel tanks. She also contributed to significant research efforts to achieve optimal results for these high-strength aluminum alloys.

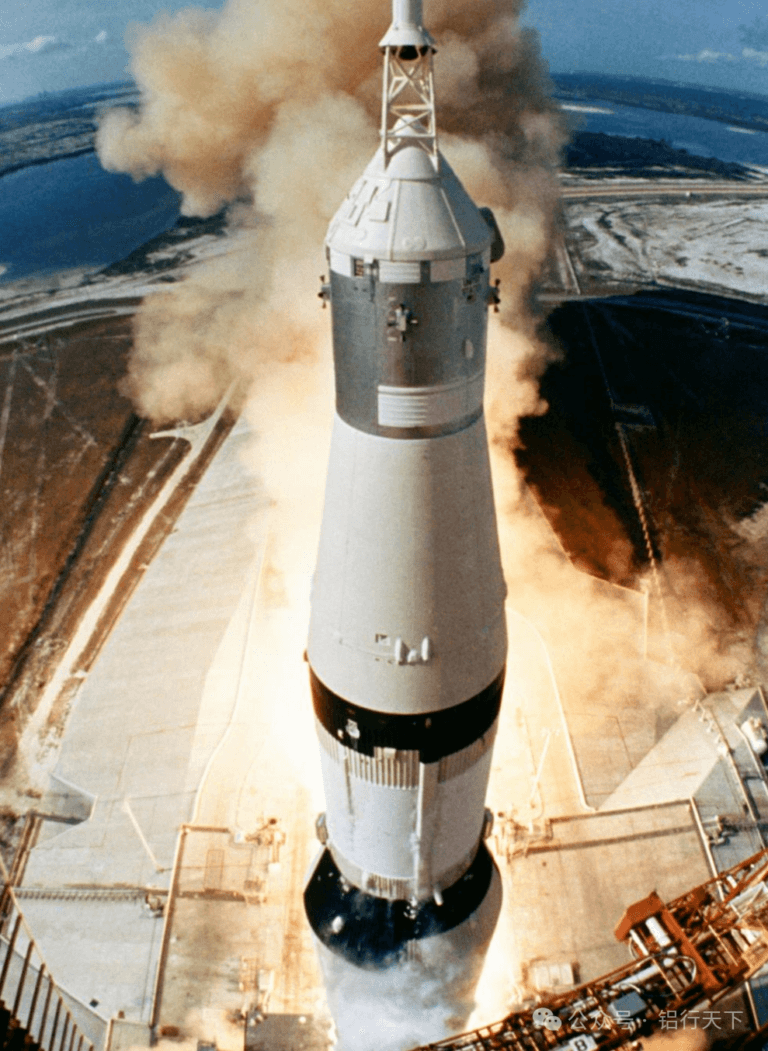

Launch of the Saturn V rocket for the Apollo 11 lunar mission, with astronauts Neil A. Armstrong as commander, command module pilot and lunar module pilot Edwin E. Aldrin Jr. Photo: NASA.

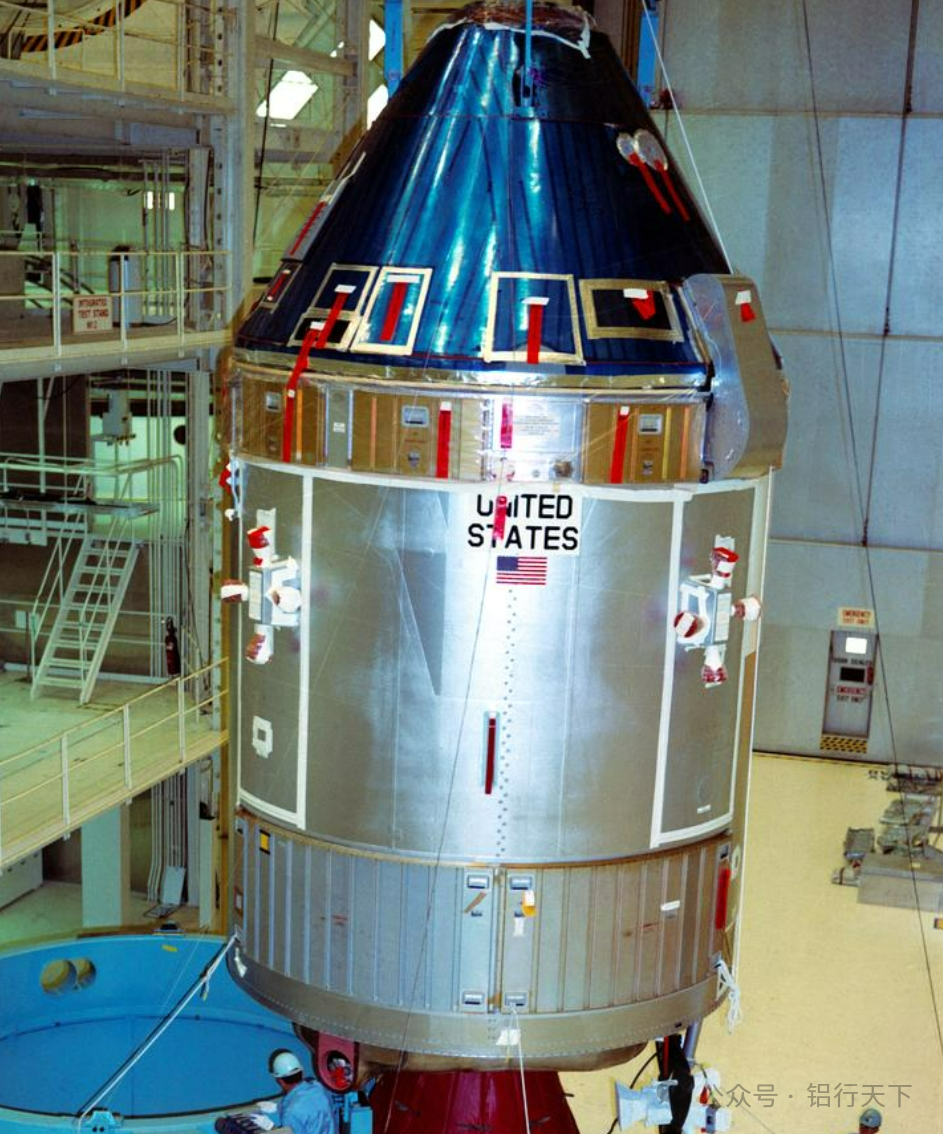

control and service module

The Command and Service Module (CSM) consists of two separate units. The command module houses the crew, spacecraft operating systems, and re-entry equipment, while the service module carries most consumables (oxygen, water, fuel, etc.) and the main propulsion system .

The control module is a conical pressure vessel (maximum diameter at base 3.9 m, height 3.65 m), consisting of an aluminum honeycomb sandwich bonded between aluminum alloy plates, with a brazed stainless steel sanitary shield. A NASA article on the construction of the module states:

The interior crew compartment consists of two elements: the cabin structure and the system support structure. The compartment structure is made of aluminum and is divided into two parts. The front section includes the tunnel, front bulkhead and front side walls. The rear section consists of a rear sidewall, a rear bulkhead and a circumferential machined ring. When connected together, these two sections form the pressure vessel of the spacecraft.

The front welded inner skin is composed of panels, four machined stringers, window frames, machined circumferential rings and fittings. The aluminum honeycomb core and outer panels are thermally bonded to the inner skin and cured in a giant autoclave (similar to a giant pressure cooker). The fasteners and fittings are then bonded to the structure to install the system support structures, wiring, piping and other equipment. The channel connected to the forward bulkhead includes a forward ring to mount the mooring ring, the snap hatch cover and the outer frame to absorb loads from the parachute deployment and recovery sling.

The welded inner skin of the tail section consists of panels, machined rings and fusion welded bulkheads. The aluminum honeycomb core and outer panels are thermally bonded to the inner skin and cured in giant autoclaves. The external frame and internal fixings are linked to the support structure of the system.

The interior cabin is completed when the front and rear components are cut circumferentially and welded onto the rings. The final assembly operation is the bonding of the aluminum honeycomb core and the facing panels.

The service module is connected to the rear of the control module and is a cylinder (3.9 m diameter, 7.6 m long) with an outer skin made of 2.5 cm aluminum honeycomb panels. thickness. The interior is divided into six sections by radial milled aluminum beams surrounding a central cylinder.

lunar module

The Eagle lunar module used in the Apollo program was made almost entirely of aluminum. For example, the cabin is mainly made of aluminum alloy, with titanium fittings and fixings. Alcoa supplied a large quantity of aluminum for the project, including aluminum honeycomb shock absorbers integrated into the module’s legs, designed to compress upon impact to protect the lunar module during landing.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.