Home trainer, bike, camera… Apple Watch? 3D printing technology can not only reduce costs but also create unique and personalized products, which is why more and more consumer products are starting to adopt 3D printing technology. A recent rumor adds another dimension to this trend. It is speculated that tech giant Apple will use titanium 3D printing technology to manufacture mechanical parts for the Apple Watch Ultra that will launch later this year.

Although it’s just a rumor at this point (neither Apple nor the associated 3D printing company has confirmed it), its sources are reliable in predicting Apple’s trends. Ming-Chi Kuo is an analyst at TF International Securities, a financial services group for the Asia-Pacific region. He is known for gathering intelligence from contacts in Apple’s Asian supply chain and has had great success in his predictions about future Apple products. Bloomberg quoted Ming-Chi Kuo last weekend as saying that Apple was using 3D printing technology to make titanium mechanical parts for the Apple Watch Ultra 2H23, using solutions from Farsoon and BLT.

The original Apple Watch Ultra was marketed as a sports watch (Image source: Apple)

Apple Watch Ultra uses 3D printing technology

This is not the first time Apple has used 3D printing technology. Forbes reported last year that the mobile device giant may already be using a solution from Optomec, a company known for its aerosol jet technology designed specifically for electronic additive manufacturing. Additionally, there are reports that the company is using this technology for prototyping. But if this rumor is true, it will be the first time that 3D printing technology becomes the core technology of Apple’s new product.

As mentioned earlier, according to Ming-Chi Kuo, this titanium alloy 3D printing technology will use solutions from Farsoon and BLT. Both Chinese manufacturers are known for their laser powder bed fusion equipment, particularly those compatible with metal powders such as titanium. Additionally, they are also known for their industrial applications in various sectors such as aerospace, healthcare and lifestyle. So, if Apple were to use 3D printing technology to manufacture device parts, it would make sense for both companies to be considered.

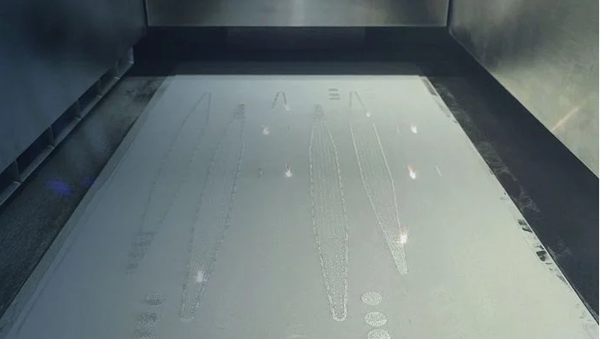

It is said that Apple will use laser metal fusion technology for the Apple Watch Ultra (Image source: Farsoon)

Still, the decision itself sparked a lot of discussion on forums. However, it is important to consider the enormous benefits that 3D printing could bring to Apple. Metal additive manufacturing has been proven to reduce costs, shorten production times and strengthen supply chains. Additionally, one of the common complaints about the Apple Watch Ultra is its size and weight, which manufacturers can address by designing more complex geometries for parts using additive manufacturing.

However, Ming-Chi Kuo mentioned that even though mechanical parts use 3D printing technology, their back-end processes still require CNC processing. Additionally, he also mentioned that he believes the new Apple Watch Ultra will serve as a test and if successful, more Apple products will start using additive manufacturing technology. In any case, Mohou.com will be attentive to any news from these two companies in the coming months.

source:3dnatives

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.