Text/Chen Jingsong, Tang Guangming, Zheng Mingming·Hunan Changgao Complete Electrical Appliances Co., Ltd.

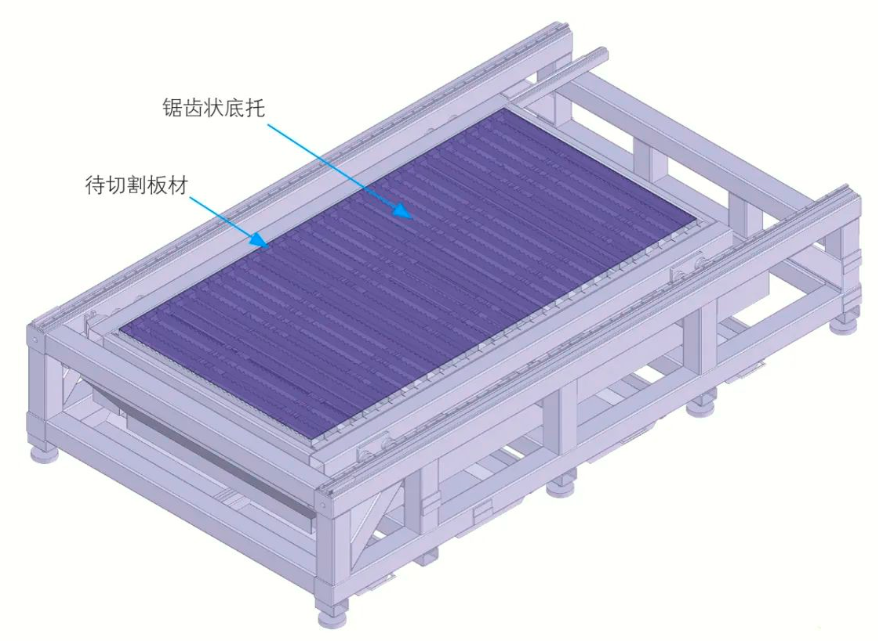

Laser cutting uses a focusing mirror to focus the laser beam onto the surface of the material to melt, vaporize and abrade the material. At the same time, compressed gas coaxial with the laser beam is used to blow the molten material and molten material. the laser beam and the material oppose each other along a certain trajectory to form a cutting seam of a certain shape to complete the cutting of the material. Laser cutting has the advantages of high precision, narrow slot, smooth cutting surface, fast speed, good processing quality and a wide range of processing materials. At present, laser cutting technology is widely used in many fields. Complete electrical enclosure assemblies are mainly made of sheet metal parts. Laser cutting has become a common processing method in the sheet metal industry due to its advantages of low processing cost, high efficiency and wide variety of processing materials. However, the sweet melon and bitter stalk are not perfect, and the associated slag and burrs that settle during their processing are troublesome for on-site managers. Burrs on the part are shown in Figure 1.

Figure 1 Burrs on the part

Causes and effects of burrs in laser processing

By understanding the working principle and daily practice of laser cutting, we can summarize the main causes of burrs in six aspects:

⑴ Deviation in the upper and lower positions of the laser beam focusing results in energy inconcentration, insufficient gasification of the workpiece, accumulation of slag that is not easy to fall off, and burrs are easily generated;

⑵The laser output power is not enough to effectively evaporate the metal, resulting in a large amount of slag and burr;

⑶The auxiliary gas type, purity and blowing pressure of the laser cutting machine do not meet the requirements, causing burrs;

⑷The cutting speed is too slow when laser cutting, which damages the quality of the cutting surface and produces burrs;

⑸ The working time of the laser cutting machine is too long, which makes the equipment unstable and causes burrs;

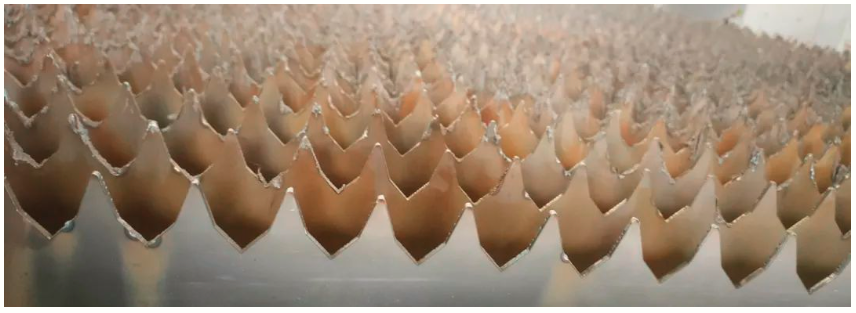

⑹ Laser cutting equipment has defects. For example, the zigzag plate of the laser base has a small serration depth and insufficient taper, so the contact area with the plate is too large, resulting in obstruction of the laser tip and laser flow. gas during processing, and it is easy to cause slag adhesion and slag rebound, forming burrs, as shown in Figure 2.

Figure 2 Schematic diagram of the basic structure of the equipment

The presence of burrs in the corners of the workpiece will seriously affect the accuracy of subsequent bending, welding and assembly, and also pose certain safety risks to operators. If the workpiece with burrs is applied to the air box of the ring main unit produced by our company, it will have a great impact on the airtightness when used in the electrical system, the burrs will fall, causing a short circuit in the circuit; or damage the magnetic field, affect the normal operation of the system or cause other hazards.

Methods to avoid burrs during laser processing

Adjust device settings

According to different processing materials, the power, air pressure, flow rate, focal length, feeding speed and other parameters are repeatedly adjusted to the optimal state, and the recorded data is saved for facilitate subsequent batch processing. It is impossible to cut exquisite pieces. only based on the parameters provided by the machine.

Select assist gas

The application of auxiliary gas will also affect the processing quality, so different auxiliary gases should be selected according to different processing materials. For example, when cutting stainless steel, it is recommended to use nitrogen as an auxiliary gas. Nitrogen is generally called an inert gas. When laser processing, nitrogen not only prevents the explosion point phenomenon during laser cutting, but also prevents the heated end. instant oxidation, making the cut end face smoother and brighter. Gas purity is also essential. Try to choose a gas of high purity.

Check equipment accessories

Equipment used for a long time will also reduce the processing quality and produce burrs due to aging, contamination and damage to key parts. If the lens is contaminated with oil, has small cracks, or the cutting nozzle is damaged, laser power transmission will be affected. These can be judged by observing whether the light spot formed is round. If the light spot is round, it means that the side distribution of laser energy is uniform and the cutting quality is high. Cutting quality can also be ensured by regular inspection. of key components.

Optimize equipment structure

In actual production, the structure of the equipment can be improved according to different parts processed. If the contact area between the sawtooth plate of the laser base and the plate is too large, it is easy to produce burrs. The taper of the teeth can be reduced and the depth of the teeth can be increased according to the specific situation, as shown in Figure 3, to avoid interference in treatment due to excessive contact area between the lower bracket and the plate. The improved bottom bracket is shown in Figure 4.

Figure 3 The schematic diagram of the structure before and after the improvement of the bottom bracket

Figure 4 Improved Bottom Support

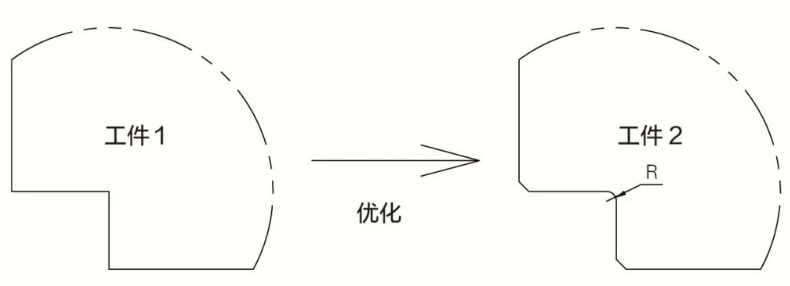

Optimize room corners

In actual production, it is also found that the transition structure of the corners of the workpiece will also have an impact on the processing quality. For example, right-angled transitions are more likely to produce burrs than rounded corners and beveled transitions. 5, it is recommended to use rounded corners and beveled corners for the transition as much as possible, which can also reduce the stress concentration in the structure.

Figure 5 Optimization of the transition structure of the corners of the room

Conclusion

Under the background of the vigorous development of China’s market economy, enterprises are constantly pursuing truth and innovation. However, while being competitive and developing, they cannot ignore the quality problems of the original products themselves. looking for new opportunities Innovation can effectively improve overall competitiveness. The laser cutting machine itself is a precision machine, and its operation is also delicate work. Often, data error will cause the laser cutting machine to operate abnormally. Therefore, the work must be rigorous and precise, as well as the equipment, gases and. the parameters should be adjusted to the best, can make the cut more qualitative.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.