Aluminum Plate CNC Processing: Step-by-step Guide

As a leading provider of five-axis CNC machining services, outstanding light has extensive experience in manufacturing high-precision aluminum sheets using cutting-edge technology. Our expertise in CNC machining allows us to produce complex parts with tight tolerances, ensuring consistency and accuracy for each piece. In this comprehensive guide, we will take you through the aluminum plate CNC machining process, from raw material selection to finishing touch.

Step 1: Material Selection

The first step in CNC machining of aluminum sheets involves choosing the right material for the job. We offer a variety of aluminum alloys including 6061, 6082 and 7075, each with unique properties and applications. The choice of the correct material depends on the intended use of the part and its design requirements. For example, 6061 is a popular choice for structural components, while 7075 is commonly used in high pressure applications.

Step 2: Design and Planning

Before starting the machining process, our team of experts reviewed the design and made the necessary adjustments to ensure that the parts meet the required specifications. This step involves checking for any errors or inconsistencies in the design and optimizing the parts for efficient machining.

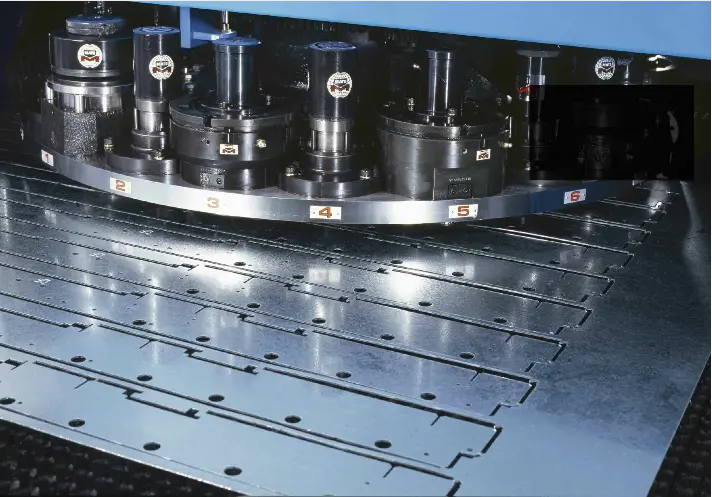

Step 3: Cutting and Milling

Using our advanced five-axis CNC machining center, we secure and mill the aluminum plates to the exact specifications. Our machines are able to handle a wide range of materials and can produce complex geometric shapes with tight tolerances. The cutting and milling process involves multiple stages, including cutting, semi-fixation and final machining.

Step 4: Turn

Once the plate is milled, it undergoes a turning process to achieve the desired shape and finish. Our CNC lathes are equipped with advanced tools and automation to ensure high speed and accuracy.

Step 5: Grinding and finishing

The final stage involves grinding and finishing the parts to achieve the required surface surface and tolerances. Our team of skilled technicians employs a variety of techniques, including belt grinding and polishing, to ensure high-quality completion.

Step 6: Assembly and Inspection

After the machining process is completed, our quality control team thoroughly inspects the parts to ensure they meet the required specifications. If necessary, we perform any other component or glitch task to complete the part.

in conclusion

Aluminum plate CNC machining is a complex process that requires attention to details and expertise. Great Light’s five-axis CNC machining capability enables us to produce high-precision parts with tight tolerances, ensuring consistency and accuracy. From material selection to finishing touch, our experienced team is committed to providing high-quality parts that meet customer needs.

Frequently Asked Questions

Q: What type of aluminum alloy do you offer?

A: We offer a variety of aluminum alloys including 6061, 6082 and 7075.

Q: Can I get a quote for my custom section?

A: Yes, please contact us according to your design and specification requirements and our team will provide quotation and lead time estimates.

Q: How long does the processing process take?

A: The processing time depends on the complexity of the parts and the materials used. Please contact us for specific estimates.

Q: What are the typical tolerance ranges for your CNC machining service?

A: Our typical tolerance range is ±0.005"However, we can adapt to stricter tolerances according to customer requirements.

Q: Can I get sample parts before production?

A: Yes, we can provide sample parts for testing and inspection before performing a complete production run.