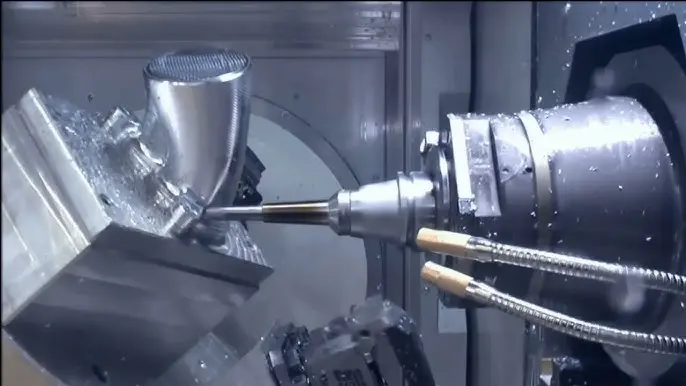

As a leading provider of five-axis CNC machining services, high-quality light has extensive experience in precise machining and manufacturing of high-quality metal parts. In this article, we will dig into the world of aluminum CNC machining and explore its benefits, applications and best practices.

Aluminum is a multifunctional material in a variety of industries, including aerospace, automotive and consumer electronics. Its high strength to weight ratio, corrosion resistance and excellent thermal conductivity make it ideal for many applications. CNC machining is an accurate and effective method for manufacturing aluminum parts, providing many benefits over traditional manufacturing methods.

Benefits of Aluminum CNC Processing

- High precision: CNC machining allows precise control of the machining process to ensure that the parts are manufactured to the exact specifications.

- Rapid production:CNC machining is a fast process that can quickly turn over time and improve productivity.

- Complex geometric shapes: CNC machining can produce complex shapes and designs, while traditional manufacturing methods will be difficult or impossible to achieve.

- Cost-effective: CNC processing reduces material waste and minimizes the need for manual labor, making it a cost-effective option for mass production.

Application of aluminum CNC processing

- Aviation Industry: Aluminum is widely used in aircraft and spacecraft due to its high strength-to-weight ratio and corrosion resistance.

- Automotive Industry: Aluminum is used in vehicle structures, including engine components, suspension parts and body panels.

- Consumer Electronics: Aluminum is used in electronic devices such as laptops, smartphones and tablets because of its excellent thermal conductivity and corrosion resistance.

- Medical equipment: Due to its biocompatibility and corrosion resistance, aluminum is used in medical implants, surgical instruments and equipment.

Best Practices for Aluminum CNC Processing

- Material selection: Choose right aluminum alloy for specific applications, considering factors such as strength, corrosion resistance and thermal conductivity.

- Tool selection: Select the right cutting tools and coatings to optimize processing performance and minimize tool wear.

- Processing parameters: Optimize machining parameters such as feed rate, spindle speed and cutting depth to achieve high quality finishes and minimize material waste.

- Post-processing: Apply after-treatment techniques such as anodizing or powder coatings to enhance the corrosion resistance and aesthetic appeal of finished parts.

in conclusion

CNC machining is an accurate and effective method for manufacturing high-quality metal parts. Its benefits, including high precision, rapid production and cost-effectiveness, make it ideal for various industries. By following best practices such as material selection, tool selection and machining parameter optimization, manufacturers can produce complex aluminum parts with high precision and surface finishes. Whether you are in the aerospace, automotive or consumer electronics industry, Great Light’s five-axis CNC machining service can help you meet your precise machining needs.

FAQs (FAQs)

Q: What is the difference between aluminum and other metals used in CNC processing?

A: Aluminum is a lightweight corrosion-resistant metal with high thermal conductivity, making it ideal for applications where strength, durability and thermal management are critical.

Q: What is the most common aluminum alloy used in CNC processing?

A: The most common aluminum alloys used in CNC processing include 6061, 6063, 7075 and 2024, each with its unique properties and applications.

Q: Can aluminum CNC processing be used for mass production?

A: Yes, aluminum CNC machining is suitable for mass production, providing fast productivity and cost-effectiveness.

Q: What post-processing technologies can be applied to aluminum parts?

A: Common after-treatment techniques for aluminum parts include anodization, powder coatings and chrome plating, which enhance corrosion resistance, aesthetic appeal and functional performance.

Q: How to choose the right CNC machining service provider for aluminum parts?

A: When choosing a CNC machining service provider, consider factors such as aluminum processing experience, equipment and expertise, as well as their ability to meet your specific requirements and deadlines.