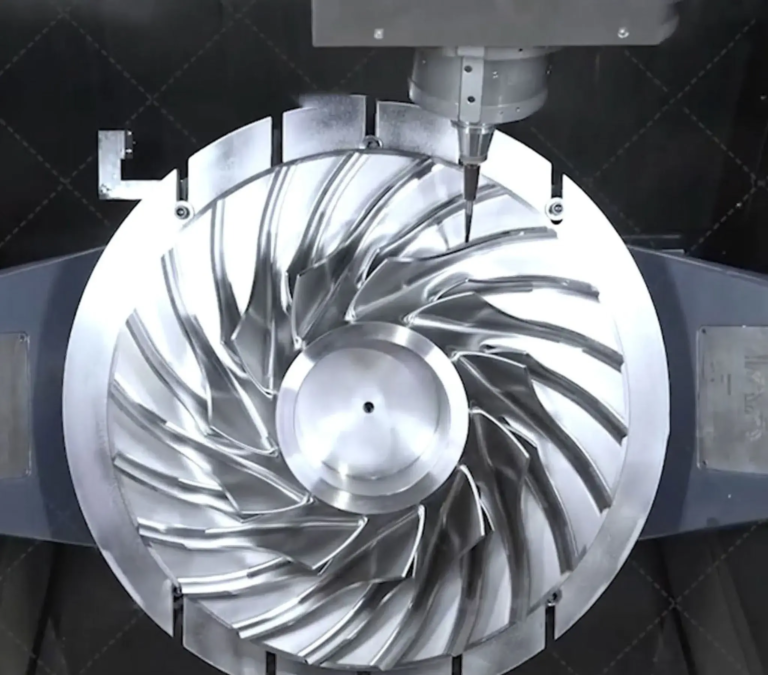

As a leading provider of five-axis CNC machining services, Great Light has established itself as the preferred solution for businesses and individuals seeking high-quality, precise metal parts. Great Light’s advanced equipment and production technologies focus on innovation and customer satisfaction, allowing companies to address even the most complex manufacturing challenges. In this article, we will dig into the world of aluminum CNC ink protection and explore its importance, benefits and applications.

Aluminum CNC ink protection refers to the process of applying a special coating or treatment on aluminum parts to prevent ink or other substances from adhering to their surfaces. This is especially important in a variety of industries such as printing, packaging and automotive, where ink or paint can damage the functionality and aesthetics of aluminum components. By applying a protective layer, businesses can ensure that their products maintain their intended performance and appearance even in environments where ink or other substances may be present.

The importance of aluminum CNC ink protection cannot be exaggerated. For example, in the printing industry, ink can adhere to aluminum plates or cylinders, causing damage and requiring expensive repairs. By applying protective coatings, printing stores can minimize downtime and maintain optimal production levels. Likewise, in the automotive field, ink or paint can damage the finish of aluminum components, resulting in a reduction in overall vehicle quality. By protecting these parts, manufacturers can ensure that their products meet the highest standards of quality and durability.

Great Light’s five-axis CNC machining service offers a range of benefits in aluminum CNC ink protection. With advanced equipment and production technology, the company can easily precisely draw Craft Complex Complex aluminum parts and coat or treat them as needed. This not only ensures that the parts are manufactured at the highest quality, but also minimizes the risk of ink or other substances damaging their surface.

In addition to its technical capabilities, it is committed to providing excellent customer service and support. From initial consultation to final delivery, the company works closely with its clients to understand their specific needs and serve them to meet their unique challenges. Whether you need customized precise machining, post-processing, or finished service, you are committed to providing high-quality solutions that exceed your expectations.

In short, CNC ink protection is a critical process and plays a crucial role in various industries. By applying specialized coatings or treatments to aluminum parts, businesses can prevent ink or other substances from damaging their surfaces, ensuring optimal performance and maintaining their intended appearance. With Great Light’s advanced five-axis CNC machining service, the company can trust that its aluminum parts will be accurately fabricated to the highest quality standards and will be protected or treated as needed.

FAQ:

Q: What is aluminum CNC ink protection?

A: Aluminum CNC ink protection refers to the process of applying a special coating or treatment on aluminum parts to prevent ink or other substances from adhering to their surfaces.

Q: Why is aluminum CNC ink protection important?

A: Aluminum CNC ink protection is crucial in various industries such as printing, packaging and automotive, and ink or paint can damage the functionality and aesthetics of aluminum parts.

Q: What are the benefits of using Great Light’s five-axis CNC machining service for aluminum CNC ink protection?

A: Great Light’s service offers a range of benefits, including precision-made parts, minimized risk of ink or substance adhesion, and excellent customer service and support.

Q: Can excellent lighting provide customized precision machining services for aluminum parts?

A: Yes, Great Light provides a custom precision machining service for aluminum parts, which is tailored to meet the unique needs and requirements of each customer.

Q: In addition to five-axis CNC machining, what other services can be provided?

A: Great Light provides a range of services, including post-processing and finishing services, to support customers throughout the manufacturing process.