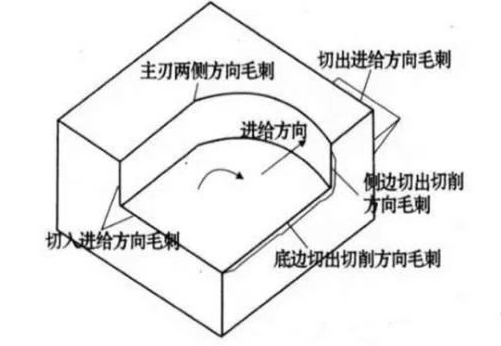

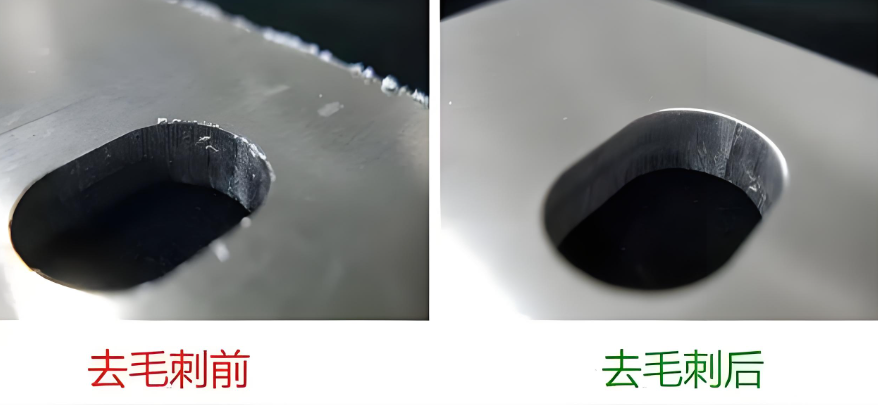

During machining, burrs (also called burrs) are tiny, irregular metal residues that form on the edge or surface of a part. Burrs not only affect the surface quality and appearance of the part, but can also affect assembly, operation and service life. Understanding the causes of burrs can help take effective steps to reduce or eliminate them.

Here are the main causes of burrs:

1. Incorrect setting of cutting parameters

Cutting speed too high

Phenomenon: Too high a cutting speed will prevent the tool from completely cutting the material, and the material will be stretched and form burrs during the cutting process.

Solution: Adjust the cutting speed within an appropriate range to ensure that the tool can cut the material smoothly.

Too much food

Phenomenon: Excessive feed speed causes excessive force on the tool during cutting, and the material cannot be cut in time, easily producing burrs.

Solution: Reduce the feed quantity appropriately to ensure a smooth cutting process.

Cutting depth is too low

Phenomenon: Cutting depth that is too shallow can cause material to be cut only on the surface without being completely removed, resulting in edge burrs.

Solution: Increase the depth of cut to ensure the material is completely removed.

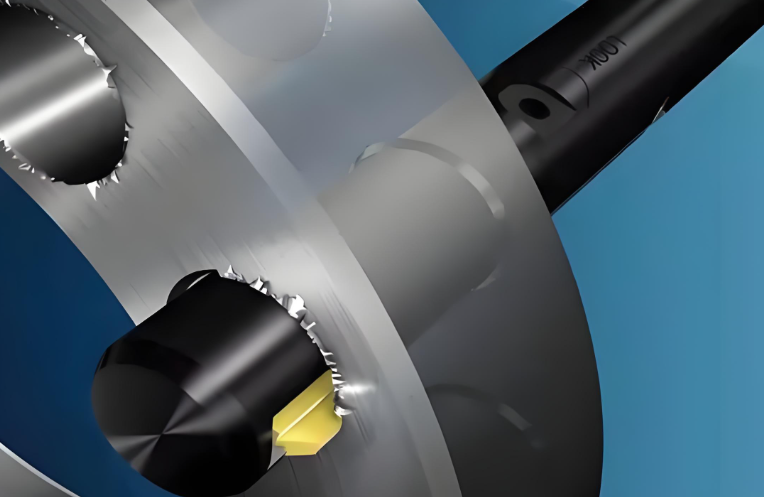

2.Tool problem

Dull or worn tools

Phenomenon: When the cutting edge of the tool becomes dull or badly worn, the material cannot be cut cleanly during cutting, and burrs are easily left on the edge.

Solution: Check the condition of the tool regularly, replace or grind the tool in time, and maintain the sharpness of the tool.

Improper tool angle

Phenomenon: Incorrect cutting angle, back angle or tip angle of the tool leads to increased plastic deformation of the material during the cutting process, thereby forming burrs.

Solution: Optimize the angle of the tool geometry to adapt it to the characteristics of the material processed,

3. Hardware issues

High tenacity material

Phenomenon: Materials with high toughness are not easily broken during the cutting process, but are prone to plastic deformation and form elongated burrs.

Solution: Choose the appropriate cutting parameters and tools to reduce plastic deformation of the material.

The hardness of the material is uneven

Phenomenon: Uneven material hardness causes large changes in cutting force during the cutting process, and burrs are likely to occur in softer or harder areas.

Solution: Ensure the stability of material quality, or improve material uniformity through appropriate heat treatment,

4. Inappropriate treatment methods

Unreasonable cutting sequence

Phenomenon: Unreasonable cutting sequence may cause workpiece deformation or incomplete fixation during the cutting process, resulting in burrs.

Solution: Optimize the cutting sequence to ensure part stability during processing.

The clamping of the part is unstable

Phenomenon: Unstable clamping of the workpiece will cause the workpiece to move or vibrate during the cutting process, causing uneven cutting and resulting in burrs.

Solution: Use appropriate clamps and clamping force to ensure the part is stable during processing.

Improper use of cutting fluid

Phenomenon: Insufficient use of cutting fluid or the wrong type leads to increased temperature in the cutting zone or insufficient lubrication, thereby increasing the formation of burrs.

Solution: Choose the correct cutting fluid and ensure adequate supply to improve cutting conditions.

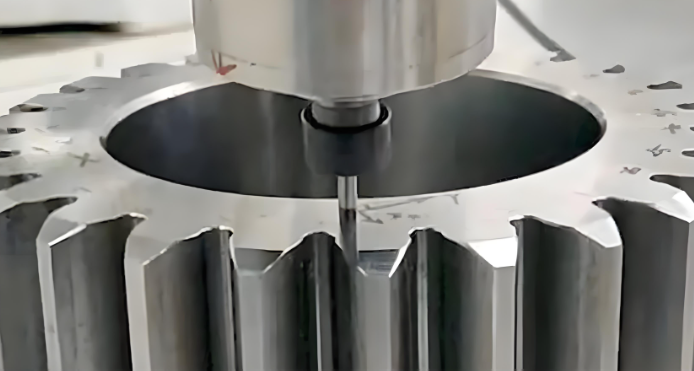

5. Machine tool problems

The machine tool is not rigid enough

Phenomenon: Insufficient rigidity of the machine tool can cause vibration during the cutting process, affecting the stability of cutting, thereby forming burrs.

Solution: Use a machine tool with good rigidity, or improve the rigidity by improving the supporting and connecting parts of the machine tool.

Insufficient precision of machine tools

Phenomenon: Insufficient precision of the machine tool will cause inaccurate relative position between the tool and the workpiece, thereby affecting the cutting quality and producing burrs.

Solution: Regularly maintain machine tools to ensure their precision and stability.

6. The design of the processing technology is unreasonable

Unreasonable cutting path

Phenomenon: Unreasonable design of the cutting path may cause sudden changes or impacts during the cutting process, resulting in burrs.

Solution: Optimize the cutting path to ensure a smooth and continuous cutting process.

Uneven cutting allowance

Phenomenon: Uneven cutting tolerance on the workpiece can make the cutting force in some areas too large or too small, resulting in burrs. Solution: Design the cutting margin reasonably to ensure the uniformity of each cut.

The generation of burrs is caused by various factors, including incorrect cutting parameters, tool problems, material properties, improper processing methods, machine tool problems, and unreasonable design of the processing process. By optimizing cutting parameters, selecting appropriate tools and materials, rationally designing processing processes, and ensuring the rigidity and precision of machine tools, burrs can be effectively reduced or eliminated, and quality processing and the surface finish of the part can be improved.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.