In drilling operations, selection of the appropriate drill bit is essential to ensure accuracy, efficiency and economy.

Generally, there are two conventional choices: solid carbide drill bits and indexable drill bits. Each type has obvious advantages and disadvantages, so this article will give a detailed description of these two hole treatments. I hope that through this article you can learn more. about them. Good selection of knives.

What problems do you encounter when dealing with hole processing tools?

1

What is an integrated drill bit?

Solid drill bits, as the name suggests, are made from different materials, such as high speed steel (HSS) or carbide. The bit itself has a cutting edge and is available in a variety of diameters, coatings, lengths and tip geometry options.

Drill bits are mainly used for processing holes with a diameter of up to 12mm (this does not mean that drill bits cannot be used for holes with a diameter > 12mm, it just means that many tools indexable hole type start from 12mm), so it is recommended to use indexable tools when this size is reached. Change insert drills (e.g. U-drills, spade drills, crown drills, etc.) as they are more cost effective in these sizes.

They are typically used with hand drills or drill presses and are capable of producing precise, high-precision holes. There are different types of drill bits, including twist drills, step drills, center drills, countersink drills, and reamers, each with specific applications and benefits.

Solid drill bits are the most common type of drill bit. They have a spiral groove design and are divided into single-ligament or double-edge belt designs, which can effectively remove chips during the drilling process. The drill bits are versatile and can be used on a variety of materials including metal, wood and plastic. They have different diameters and lengths, the most common are short (3xD) and elongated (5xD). Of course, many factories now also include 7x diameter and 8x diameter as standard products in their samples. diameters exceeding 10 times in their samples, of course, the above. The dimensions mentioned are for both internal and external coolant, but when alloy drill bits process holes they may extend the dimensions, especially where higher rigidity and precision are required. In addition, the processing of parameters (for example: feed, efficiency, linear speed). are much better than those of high speed steel drills. High speed steel drill bits are generally used in the general fields of metal processing, woodworking and construction (for example, pistol drills are also used in domestic life).

Step Drill Bits: Step drill bits are designed as multi-edged drill bits with a stepped tapered cutting edge that gradually increases in diameter. Each step has progressively larger diameters, allowing holes of different diameters to be drilled in a single operation. Step drill bits are commonly used in sheet metal processing and electrical work where precise holes of different sizes must be created. They can also be used to deburr or enlarge existing holes.

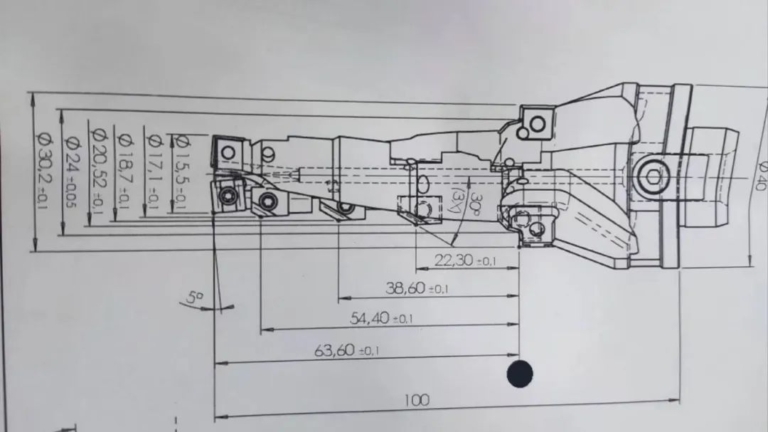

PS: Here is a drawing of a super step diamond. The dimensional accuracy and design are a bit anti-human. It comes from an Italian brand.

Countersink drills: Countersink drills are integrated tools that combine drilling and chamfering functions. They have a tapered cutting head with multiple spiral flutes that create chamfered grooves in the drilled hole opening. Countersink bits are often used to remove burrs or sharp edges from holes so that screws or fasteners are flush with the surface of the material (like what we often call countersunk screw holes). They are frequently used in woodworking, metalworking and assembly applications.

Reamers: Reamers are solid drill bits used for precise sizing and dressing. They feature multiple cutting edges and are used to improve drilling accuracy, surface finish and dimensional tolerances. Reamers are commonly used in metalworking applications, such as automotive manufacturing and machining, where high precision holes are required.

2

What is an indexable drill?

Replaceable Drill Bits Unlike drill bits, replaceable drill bits consist of two main components: the drill shank and the replaceable blade. The drill shank has replaceable fixed blades, such as production drills, U-drills and crown drills. Crown drill blades can be sharpened several times.

PS: Here is a photo of an indexable crown + outer edge + guide. Can you guess who owns the diamond?

The advantage of replaceable drill bits is that worn or damaged inserts can be easily replaced without having to throw away the entire tool holder. This makes it more cost effective and economical in a mass production environment. It is generally recommended to use replaceable drill bits when processing diameters greater than 12mm. Of course some brands made crown drills up to 4mm, I’m not sure here. How economical is this? I think the price of such a 4mm crown diamond will be capped. If you have used a 4mm crown diamond, you may wish to share your thoughts in the comments box.

Replaceable drill bits come in a variety of styles, including U-shaped drill bits and modular drill bits. Let’s talk briefly:

A U-bit is an indexable bit that uses replaceable blades. These blades have built-in drill processing features. U drill bits can be used to process stainless steel, cast iron, steel parts, etc. Blades can be replaced when worn, extending tool life and reducing costs. U-shaped diamonds are commonly used in high-volume production environments such as automotive and aerospace manufacturing. They are suitable for drilling a variety of materials including metals, plastics and composites.

Modular Drill: Consists of a blade and tool holder assembly, including a tool holder, an intermediate center drill and a blade. This modular design allows customization and flexibility for different drilling requirements, for example a modular drill bit with a chamfered bushing for multiple diameters, such as stepped holes. Modular drill bits are often used in industries that require versatility and rapid tool changes, such as oil and gas, where drilling conditions can vary.

Here are two photos to share with you to help you understand this product.

3

Advantages of integrated drills

Solid drills and indexable drills each have their own advantages and are suitable for different applications. Here are some advantages of solid drill bits over indexable drill bits:

Cost-effective on smaller diameters: Compared to indexable drill bits, solid drill bits tend to be more cost-effective for small drilling projects and repeated use, and alloy and high-speed steel drill bits can be repaired multiple times by grinding, this kind of economy. It’s still very good for the factory. They generally have a lower initial cost because no additional blades or indexable parts are required.

Simplicity: The overall design of the drill bit is simple and easy to use. Typically made from high speed steel or carbide, no additional components or blade replacements are required. This simplicity makes solid drill bits easy to handle, install and use in manual drilling operations.

Precision: Solid drill bits provide high precision and accuracy in drilling operations. They have specific cutting edges that ensure consistent hole quality and dimensional accuracy. Solid drill bits are typically used in applications that require precise hole diameter and positioning, such as machining critical components.

Versatility: Solid drill bits come in a variety of sizes, tip geometries and materials for drilling different materials and sizes. They can be used for general drilling in various industries including metalworking, woodworking and construction.

Variety of sizes: Compared to indexable bits, solid bits are generally more flexible in size, which can be advantageous when drilling in confined spaces or restricted areas. Solid drill bits are designed to provide better machining performance in certain applications.

Low time cost: solid drills do not require the time required for changing inserts required by indexable drills. Since there are no inserts to change or adjust, the integrated drill bits install quickly and efficiently, reducing downtime and increasing productivity.

Rigidity and stability: Thanks to its one-piece construction, the integrated drill offers excellent rigidity and stability. This increases precision and accuracy during drilling operations.

Superior Performance: Solid drill bits are known for their high cutting speeds, ability to use higher cutting parameters and chip evacuation capabilities, ensuring efficient material removal and reduced cycle times.

4

Advantages of indexable drills

Versatility: Indexable drills provide versatility in cutting edge and insert geometries. Different inserts can be selected to meet specific drilling requirements such as material type, hole diameter and cutting conditions. This versatility allows the drilling process to be customized and optimized.

Longer life: Indexable drill bits generally have a longer life than solid drill bits. When the blade becomes dull and no longer has cutting power or is damaged, it can be easily replaced, extending the overall life of the bit. This reduces downtime when changing tools and increases productivity.

Cutting Performance: Indexable drill bits provide enhanced cutting performance with specially designed inserts. Inserts can be optimized for specific materials and cutting conditions, resulting in better chip evacuation, reduced cutting forces and longer tool life. This makes indexable drill bits particularly advantageous in difficult drilling applications.

Reduced machine downtime: Indexable drill bits enable quick and efficient insert changes, reducing machine downtime when changing tools. This is especially important in high-volume environments where downtime must be minimized to maintain productivity.

Flexibility: Indexable drill bits provide flexibility with inserts in a variety of sizes, geometries and coatings. This flexibility allows easy adaptation to different drilling requirements and materials, thereby optimizing performance and efficiency.

Improved chip evacuation control: Indexable drill bits typically feature specialized chip evacuation designs and insert geometries for efficient chip evacuation and improved surface finish.

5

How to choose between solid and indexable drills

When choosing between solid and indexable drills, several factors should be considered:

Application Type: Consider the size, materials and specific requirements of your drilling application. Solid bits are suitable for a variety of drilling tasks, while indexable bits excel in high-volume production environments.

Cost considerations: Evaluate profitability based on the size of your operation. For small-scale operations, solid drills may be a more economical option, while indexable drills offer advantages for large-scale, continuous drilling tasks.

Tool life and maintenance: Evaluate expected tool life and maintenance needs. Indexable drill bits have a long life thanks to replaceable inserts, reducing the need for frequent tool changes and associated downtime.

Precision and performance: Consider the level of precision and performance you want for your drilling operation. Solid drill bits provide exceptional rigidity and stability, ensuring precise drilling results, while indexable drill bits provide flexibility and adaptability to changing drilling conditions.

6

To summarize

The choice between solid and indexable drills depends on various factors such as the type of application, size of operation, cost considerations, expected tool life and required precision. Known for their versatility, stability and performance, solid drill bits are the first choice for many drilling tasks. Indexable drill bits, on the other hand, are particularly popular in high-volume drilling operations because they offer cost-effectiveness, flexibility and extended tool life.

By understanding the features and benefits of solid and indexable drill bits, you can make the right decision for your specific drilling needs. Ultimately, choosing the right drilling tool will increase your productivity, accuracy and overall operational success.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.