What is trochoidal milling

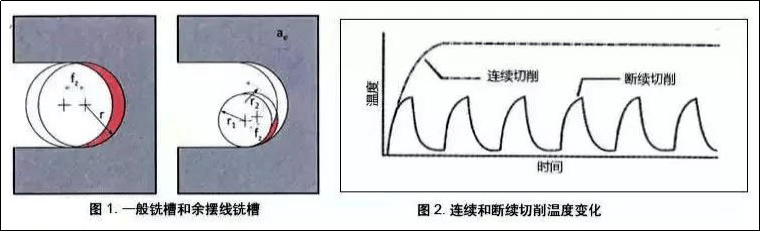

End mills are mainly used for machining complex planes, grooves and profiles. Unlike turning, in machining complex grooves and profiles of these parts, the design and selection of milling paths is also very important. For example, when milling slots using the general method, the maximum contact angle of the arc processed at the same time can reach 180°. The heat dissipation conditions are poor, and the temperature rises sharply during processing.

If the cutting path is changed and the cutter rotates during rotation, the contact angle and the amount of removal per revolution are reduced, the cutting force and cutting temperature are reduced, and the service life of the cutter is reduced. The tool is extended. As a result, cutting can be continued for a long time, as shown in Figure 1, called trochoid milling.

Its advantage is that it reduces the difficulty of cutting and guarantees the quality of processing. Reasonable selection of cutting parameters can improve efficiency and reduce costs, especially when processing difficult-to-machine materials such as heat-resistant alloys and very hard materials. it has great development potential, which may be the reason why the industry pays more and more attention and chooses trochoid milling method.

Technical advantages

The hypotrochoid is also called trochoid and extended epicycloid, which is the trajectory of a point outside or inside the moving circle when the moving circle extends in a certain straight line and rolls without sliding. It can also be called a long (short) cycloid.

Trochoidal machining involves using an end mill with a diameter smaller than the width of the groove to process half of the arc of the groove into a small part of the arc on its side. It can process various profile grooves and cavities. In this way, in theory, an end mill can process grooves and profiles of any size larger than itself, and can also easily process a series of products.

With the development and application of computer numerical control technology, the controllability of milling paths, optimization of cutting parameters and the multifaceted potential of trochoidal milling are increasingly adopted and used. And it has been considered and appreciated by parts processing industries such as aerospace, transportation equipment, and tool and mold manufacturing. Particularly in the aerospace industry, commonly used titanium alloy and nickel-based heat-resistant alloy parts have many difficult-to-machine characteristics, including:

High heat resistance and hardness make it difficult for the tool to resist or even deform during processing;

High shear strength makes the blade easy to damage;

Low thermal conductivity makes it difficult for high heat to escape from the cutting zone, where the temperature often exceeds 1000ºC, worsening tool wear;

During processing, the material is often welded to the cutting edge, forming a built-up edge. Poor quality of the machined surface;

The phenomenon of work hardening of refractory nickel-based alloy materials with an austenitic matrix is serious;

Carbides present in the microstructure of nickel-based heat-resistant alloys can cause abrasive tool wear;

Titanium alloys are very chemically active and chemical reactions can also aggravate damage etc.

These difficulties can be addressed continuously and gently using trochoidal milling technology.

Due to the continuous optimization of tool materials, coatings, geometric shapes and structures, as well as the rapid advancement of intelligent control systems, programming technologies and fast and efficient multifunctional machine tools, High-speed cutting (HSC) and high-efficiency cutting (HPC) processes have also reached new heights. High-speed machining mainly considers increasing speed. Efficient machining should not only consider improving cutting speed, but also consider reducing auxiliary time, reasonably setting up cutting parameters and cutting paths, performing composite machining to reduce processes , to increase the metal removal rate per unit time, while extending tool life and reducing costs. , think about environmental protection.

Technological outlook

The application data of trochoidal milling in aircraft engines is shown (as shown in the table below)

When processing Ti6242 titanium alloy, the unit tool cost can be reduced by nearly 50%. When processing grooves on nickel-based heat-resistant Inconel 718 alloy parts, labor hours can be reduced by 63% and overall cost and tool demand can be reduced by 72%. Tool costs can be reduced by 61%. Working hours for processing X17CrNi16-2 can be reduced by about 70%. Due to these good experiences and results, the advanced trochoidal milling methods have been applied to more and more fields, have also gained attention and started to be applied in some fields of micro-precision machining.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.