Today I would like to share with you an article about tool handle interface (BT/BBT/HSK)

Tool holders are the tools that connect the cutting tool to the machine tool. Their role is to serve as an interface between the cutting tool and the machine tool.

Tool holder performance directly affects machining accuracy. To fully demonstrate the performance of machine tools and cutting tools, tool holders must have high runout accuracy, rigidity (resistance to deformation) and clamping force. Even if the spindle rotates at high speed, the tool holder must meet these requirements without being affected by centrifugal force or other external forces. Runout accuracy is a measure of how much a tool rotates relative to its center axis. The higher the runout accuracy, the lower the tool jitter and the higher the machining accuracy.

Tool holders are defined by standards in terms of shape and size. Machining centers include BT, BBT, HSK, etc. Lathes, turning centers and multitasking machines on lathes have CAPTO interfaces (exclusive to Sandvik).

1

About BT tool holder interface

BT stands for “Morse Taper” and is marked with a tapered shank. It is used by fixing it on the spindle of a machining center. The BT handle was originally developed in Japan and is widely used in manufacturing sites around the world.

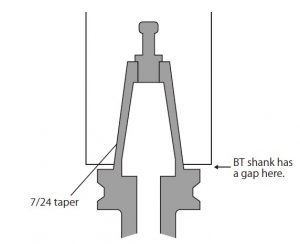

The cone size is fixed and is a 7/24 cone, where the diameter is 7mm smaller in the axial direction than 24mm. Depending on the length of the diameter of the largest part of the cone, there are nominal numbers such as BT30, BT40 and BT50.

DIN2080 NT taper shank, 7/24 taper, used for older machine tools with manual tool change. The standard of taper parts is the same as other 7/24 taper shanks.

2

About BBT tool holder interface

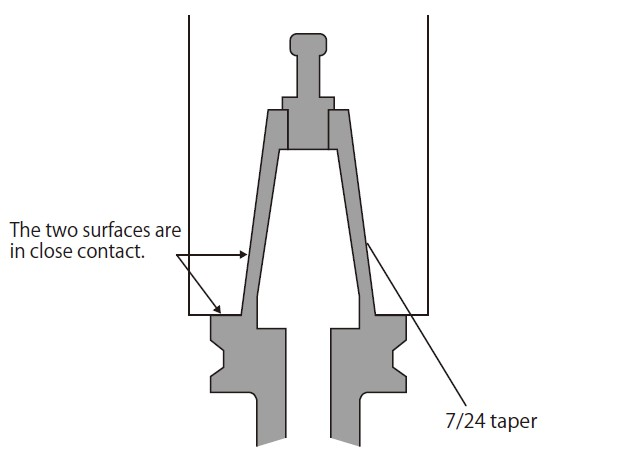

BBT knife handles are a standard independently developed by Japanese knife handle manufacturer Daishowa. It is difficult to distinguish between a BBT handle and a BT handle at first glance, but the biggest difference is that the BBT handle is a dual contact pin system. “Double contact” means that the shank contacts both the spindle taper and the spindle surface.

For BT rods, only the tapered part of the rod is in close contact with the pin, and there is a gap between the rod end face and the pin end face. In this case, when the spindle rotates at high speed, the spindle hole enlarges due to centrifugal force, causing the tool holder to be pulled into the spindle hole, which changes the position of the tool and can have a negative impact on machining. accuracy, especially in the Z axis direction.

On the other hand, with BBT rods, the rod end face and the pin end face are in close contact, so the rod is not pulled into the pin hole and the Machining can be carried out with high precision even at high spindle speeds. Due to the close contact between the two surfaces, the BBT handle is harder than the BT handle and can control vibration during machining. The BBT handle can also be used interchangeably with the BT handle, making it easy to use.

PS: This is just a description of the difference between BT tool holders and BBT tool holders. In comparison, BT interface tool holders are much more versatile than BBT interface tool holders.

3

About HSK tool holder interface

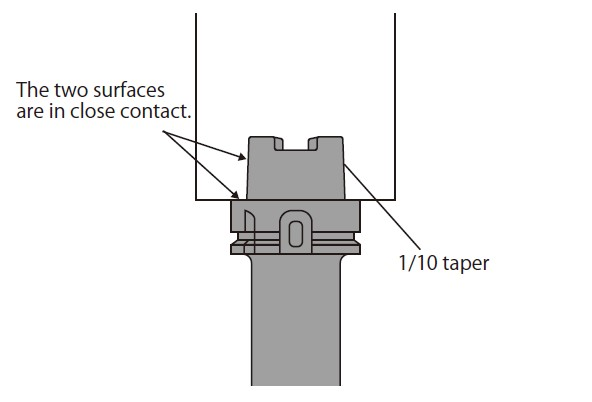

HSK is a tool holder standard developed in Germany for high speed rotation. HSK stands for “Hohlschäfte Kegel” in German, which means conical hollow shank.

The HSK shank features a short overall frame length and a lightweight hollow internal structure to support high-speed spindle rotation. The taper size is fixed and uses a 1/10 taper where the diameter is 1mm shorter than 10mm in the axial direction. It provides high rigidity through a double contact system in which the tapered component and the end face of the shank are in close contact with the spindle. Shaft sizes are also specified, with six main types used: 25, 32, 40, 50, 63 and 100. The smaller the number, the smaller the handle size.

There are many types of tool holders, such as heat shrink, hydraulic, ER tool holders, etc. We will continue to discuss this in detail in the next issue.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.