As a manufacturer of five-axis CNC machining, Great Light is committed to providing high-precision machining services to customers around the world. In this article, we will explore the advantages of CNC dual-column machining centers and how they can benefit your business.

CNC double-column machining center: What is this?

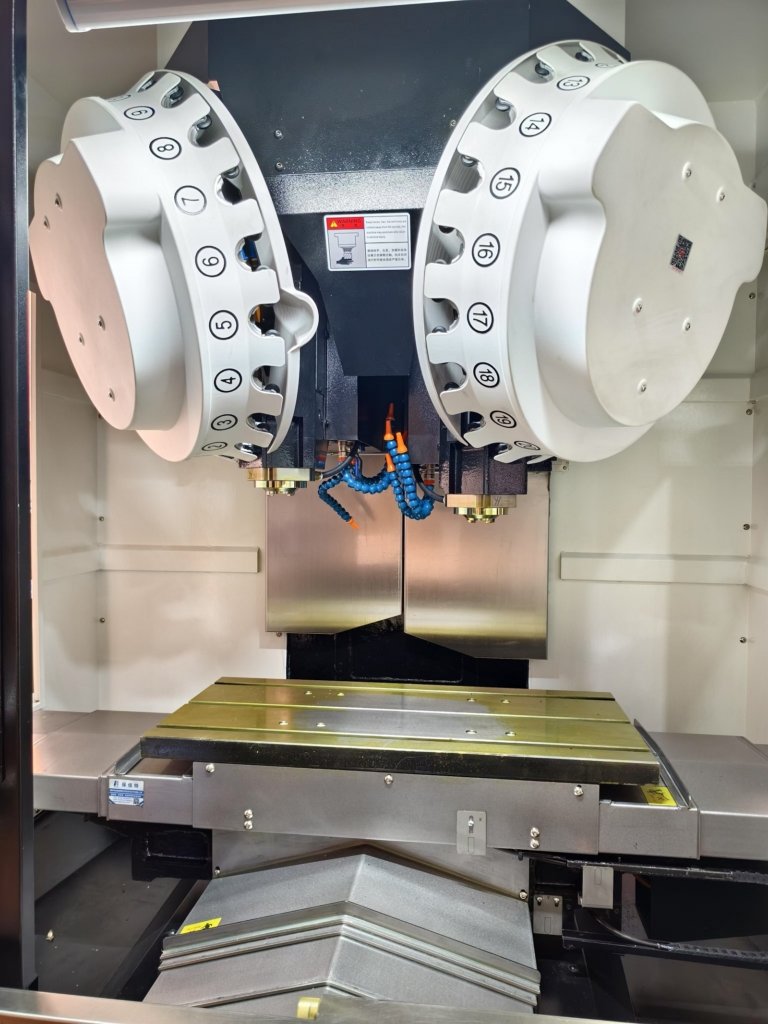

The CNC double-column machining center is a computer numerical control (CNC) machine that uses two vertical columns to support the gantry and spindle. This design allows for a higher level of flexibility and precision during machining. Unlike single-column machining centers, a dual-column machine can handle larger and heavier workpieces, making it ideal for complex manufacturing tasks.

Advantages of CNC double-column machining center

1. Improved accuracy

The dual-column design provides a more stable and rigid frame, thereby improving machining accuracy and accuracy. This is especially important for complex parts where smaller tolerances are critical.

2. Enhanced stiffness and stiffness

The dual-column design produces a stiffer, more rigid frame, which reduces vibration and improves overall stability. This allows for more efficient processing and reduces material waste.

3. Increased capability

Double-layer machining centers can handle larger and heavier workpieces, making them suitable for industries that require mass production.

4. Improved finish

The dual column design allows for smooth and precise movement, providing better finish and reducing material removal.

5. Reduce cycle time

With the ability to handle larger and heavier workpieces, a double-layer machining center can significantly reduce cycle time, thereby increasing productivity and productivity.

6.5-axis machining capability

The double-layer machining center can accommodate 5-axis machining functions, allowing for complex surface treatment and precise formation.

Benefit for your business

- Improve efficiency: With cycle time reduced and accuracy increased, your business can benefit from increased productivity and reduced production costs.

- Enhanced competitiveness: By providing high-precision machining services, your company can distinguish itself from its competitors and attract more customers.

- Expand your capabilities: With the ability to handle larger, heavier artifacts, your business can expand its customer base and work on more complex projects.

in conclusion

In short, CNC double-row machining centers provide a series of advantages for enterprises that require high-precision machining. From improved accuracy to expanded capacity, these machines can help you improve efficiency, competitiveness, and profitability. From a good point of view, we understand the importance of precise machining and provide a range of five-axis CNC machining services to meet your unique needs. Please contact us for more information on our processing capabilities and how we can help you achieve your production goals.

FAQ

Q: What types of materials can CNC double column machining centers handle?

A: Most metals, including aluminum, steel, titanium and stainless steel, can be processed through CNC double column machining centers.

Q: What is the typical application of CNC double-column machining center?

A: CNC double-column machining centers are commonly used in industries such as aerospace, automotive, medical, and oil and gas, where high-precision processing is crucial.

Q: Can CNC double-row machining center perform 5-axis machining?

A: Yes, some CNC double-row machining centers can perform 5-axis machining, allowing for complex surface treatments and precise formation.

Q: How does the size of the workpiece affect the selection of the CNC machining center?

Answer: When choosing a CNC machining center, the size of the workpiece is an important consideration. Double-layer machines are ideal for larger, heavier workpieces, while single-row machines are better for smaller parts.