Advantages and applications of 45 steel CNC machining

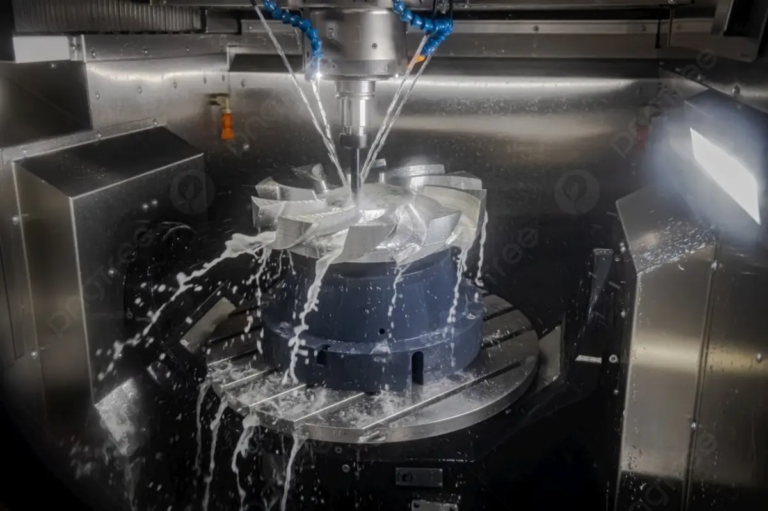

45 steel, also known as 45# steel, is a carbon steel containing 0.45% carbon content. This is a popular choice for CNC machining due to its excellent strength, hardness and machining. In this article, we will explore the advantages and applications of 45 steel CNC machining.

Advantages of 45 Steel CNC machining

- High strength and hardness:45 steel has high tensile strength and hardness, which is very suitable for applications requiring high strength.

- Good wear resistance:45 steel is resistant to wear, making it suitable for applications where parts are subject to friction and wear.

- Easy to mechanical:45 steel is easy to process using CNC processing technology, thereby reducing production time and cost.

- Cost-effective:45 steel is relatively cheap compared to other materials, which makes it a cost-effective for many applications.

- Corrosion resistance:45 steel has natural corrosion resistance and requires minimal surface treatment.

- High precision:45 steel can be processed to a high degree of accuracy, making it suitable for applications where accuracy is critical.

- aesthetics:45 steel can be processed to a high gloss, making it very suitable for applications where appearance is important.

- Recyclable:45 steel is fully recyclable, reducing waste and environmental impact.

- High temperature resistance:45 steel can withstand high temperatures, making it suitable for applications involving high temperature processes.

- Resist fatigue:45 steel is resistant to fatigue, making it suitable for repeated loading and unloading of parts.

Application of 45 steel CNC processing

- Aviation Industry:45 steel is used in aerospace applications due to its high strength, hardness and corrosion resistance.

- Automotive Industry:45 steel is used in the automotive industry for engine components, transmission parts and other critical components.

- Medical industry:45 steel is used in medical applications requiring high strength, hardness and accuracy, such as surgical instruments and medical implants.

- Machinery Industry:45 steel is used in mechanical applications requiring high strength and hardness, such as gears, shafts and other moving parts.

- HVAC Industry: 45 steel is used for heating, ventilation and air conditioning (HVAC) due to its corrosion resistance and high strength.

- Robot industry:45 in robotic applications requiring high strength, hardness and accuracy, such as in robotic components and mechanisms.

- Sports equipment industry:45 steel is used in sports equipment such as golf clubs, bicycle components and other high-performance equipment.

in conclusion

45 Steel CNC machining offers many advantages and applications due to its high strength, hardness and machining. From aerospace to medical equipment, 45 steel is a popular choice for a wide range of industries. 45 Steel CNC machining is an attractive option for manufacturers looking for reliable and durable materials, thanks to its high precision, cost-effectiveness and recyclability.

FAQs (FAQs)

- Q: What is 45 steel?

Answer: 45 steel, also known as 45# steel, is a carbon steel containing 0.45% carbon content. - Q: What are the advantages of 45 steel CNC processing?

Answer: The advantages of 45 steel CNC machining include high strength, hardness, machining, cost-effectiveness, corrosion resistance, high precision and aesthetics. - Q: Where are 45 steel usually used?

A: 45 steel is usually used in the aerospace, automotive, medical, mechanical, HVAC, robotics and sports equipment industries. - Q: What are the benefits of using 45 steel in CNC processing?

A: The benefits of using 45 steel in CNC machining include reduced production time, reduced cost and higher accuracy. - Q: Can 45 steel be processed to a height of accuracy?

A: Yes, 45 steel can be processed to a height of accuracy to make it suitable for applications where accuracy is critical.