Introduction: As the pandemic has spread over the past two years, we have begun to realize how easily economic sustainability can be disrupted. Its negative impact on supply chains and the global economy is so severe that governments around the world are implementing various initiatives to try to reverse the trend. For example, President Biden’s plan to advance additive manufacturing (AM forward), India’s National Strategy for Additive Manufacturing (AM)。

Globally, commercial and passenger transportation, such as trucks, buses and rail, are also victims of this trend. These industries are in the midst of a deep downturn due to falling demand, labor shortages and supply chain delays. Many of these manufacturers began implementing custom product configurations to maintain a competitive advantage, but their ability to supply these products was severely impacted. Antonio, president of John Deere Argentina–Garcia said:“There are few parts more expensive than those that cannot be manufactured on time. “Like many others currently, he recognizes the need to implement more agile product innovation and flexible manufacturing processes to maintain a sustainability strategy and ensure business growth in this new post-pandemic commerce reality.

Significant reductions in the movement of goods and passenger transit have forced commercial freight companies and public transport operators to park large parts of their assets. They now have the capacity to return these assets to service, but they require a skilled maintenance workforce and finding the right replacement parts is a challenge. In light of this, transportation manufacturers and direct suppliers are re-evaluating their financial strategies to achieve resilient supply chains. They are beginning to place increasing emphasis on speed of critical parts and availability of components, consolidating vertical processes and partnering with regional suppliers located near their assembly sites.

Additive manufacturing (AM) has proven its usefulness in supporting economic sustainability by increasing productivity. Additive manufacturing can facilitate rapid innovation and reduce90%inventory levels, increasing speed to market for3times. This will bring endless benefits, including reducing the risk of potential delays, as well as streamlining assembly operations and reducing labor. Additionally, product quality is improved through integrated components made using additive manufacturing technology, thereby increasing reliability. As a result, the need for technical support is reduced, thereby reducing the number of spare parts (up to60%). Since there are fewer inventory requirements, there is also less need to manage abandoned inventory parts when the product is retired.

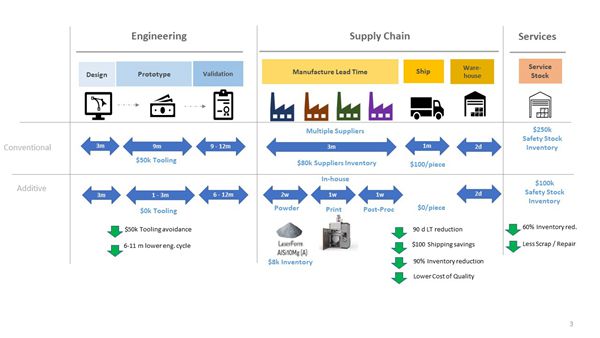

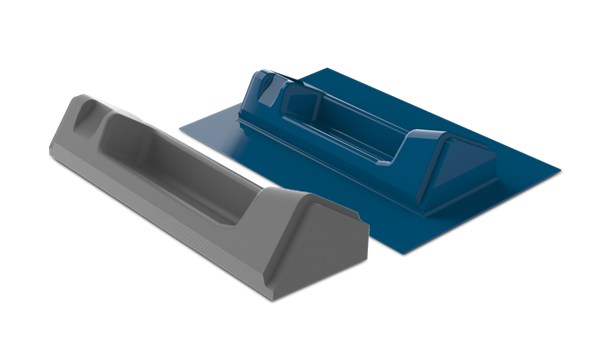

picture1. locomotiveIGBTComparison of traditional and additive manufacturing processes for phase module heat sink

Shows the use of additive manufacturing to reduce manufacturing cycle times, avoid production tooling, and reduceIn progressbenefits.

Additive manufacturing also has great benefits in terms of environmental sustainability. Because additive manufacturing can produce parts that require fewer materials, manufacturing aids and tools than subtractive manufacturing, thereby reducing waste. Being able to produce production parts and tools on demand, rather than storing them on shelves, also saves warehouse space while eliminating the need to store expensive inventory to accommodate charges abandoned products. Finally, because additive manufacturing provides the design freedom needed to create parts that would be impossible to produce with traditional manufacturing techniques, it provides engineers with a way to design applications rather than manufacturing capabilities, allowing them to to develop more energy-efficient products.

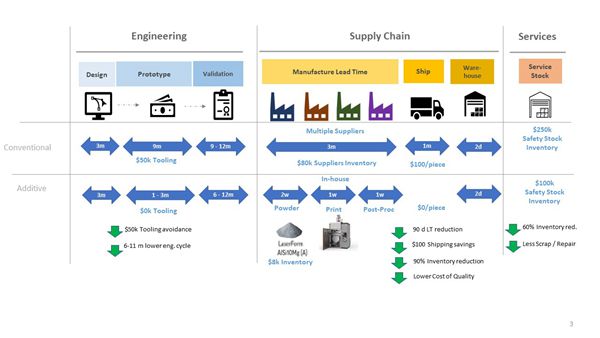

picture2. exist3D systemsofDMP Flex 350 doubleUse onLaserForm AlSi10Mg (A)Material3DOptimized, integrated printed sectioning and assembly of dual pneumatic valves, resulting in reduced mass compared to traditional manufacturing42%and canceled15parts.

Additive manufacturing of80Since its inception, it has continued to evolve with the addition of many types of printing technologies (such as photopolymers, powder bed fusion, direct to metal printing, etc.). We also see manufacturers designing an increasing number of materials to meet end-user production needs and integrating advanced software applications to maximize design freedom. Additive manufacturing has become a transformational engineering tool for transportation innovation and a key accelerator of vertical integration strategies, with a simpler interface for easier adoption. Additive manufacturing is not only a new production model, it enables a different paradigm with unique business benefits.

Tool-less production parts

Additive manufacturing is an inherent process that eliminates a major artifact from the production process.–tool. The ability to produce parts directly from digital simulations not only makes the process more efficient, but also enables decentralization of business models, rapid adaptation and delivery of customer experiences, and the ability to do so with less overhead manufacturing and waste.

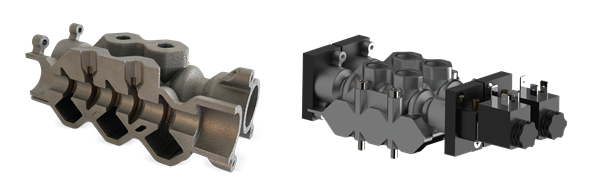

picture3. exist3D systemsbusinessDMP Flex 350 doubleUse onLaser Shape AlSi7Mg0.6(A) materials print an optimized cross-section of a liquid-cooled heat exchanger that saves money compared to traditional air-cooled radiators.83%space and canceled97parts.

Digital inventory management

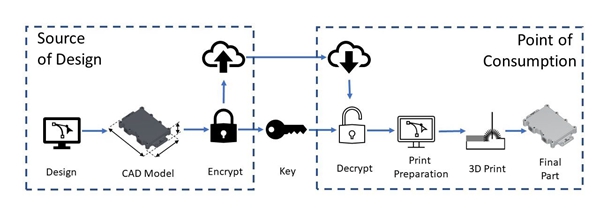

Due to the rapid development of digital encryption and intellectual property protection technologies, such as digital rights management (GDN) or blockchain system, protecting3Dmodel and3DPrinting parameters are a reality perfectly integrated into additive manufacturing technology. Design owners can now publish digital information globally, control the number of physical parts that will be produced and ensure quality, while remote users or manufacturers can print on demand without the need for shipping, insurance, storage or inventory management.

picture4. encryption3DGraphical representation of the model and all technical data, a digital key can control the quantity to be printed and its manufacturing parameters such as material, tool path, temperature, speed, etc.

rapid production tools

Commercial and public transportation require much larger parts than the automotive industry, and even as additive manufacturing technology continues to grow in productivity and build size, some critical parts remain unavailable with current methods.3DProduction of printers. Many parts (such as large metal castings, exterior body parts, large interior panels) also cannot be produced as efficiently as expected to meet the needs of the end consumer and therefore must be manufactured in a traditional manner . In these cases, additive manufacturing is the ideal solution to quickly create low to medium weight molds and casting patterns, whether sacrificial or reusable, with the advantage of being able to be kept in storage. as digital inventory tools and eliminate the need for environmentally controlled storage. space for years.

picture5. to useTitan Atlas 3.6AndPC-GF10,by10%The filling density isFDMVacuum forming molds printed inEN 45545-2:2013 R1,to usePCThermoforming of a plate3mmENSubway sign.

Leveraging Additive Manufacturing to Accelerate Transportation Innovation

Businesses with a strong long-term vision for sustainability should strive to operate in ways that promote economic growth, solve social challenges, and protect the planet by using renewable resources and eliminating waste. Advanced transportation manufacturers and their direct suppliers are re-evaluating their financial strategies to achieve resilient supply chains: with an increasing emphasis on speed and availability of critical components, many are doing so by integrating additive manufacturing in their production flow to succeed. For those considering this path, understanding the initial investment level, the technology suited to the business needs, and technical training requirements can seem daunting. This is where engaging strategic partners can play an important role in providing technical assistance and end-to-end solutions that not only help implement AM adoption but also maximize the benefits for their business.

source:

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.