Unlock the Power of Delcam Powermill: Revolutionizing Machining with Cutting-Edge Technology

In today’s fast-paced manufacturing world, efficiency, precision, and innovation are key to staying ahead of the competition. Delcam Powermill, a leading machining solution, has been at the forefront of revolutionizing the industry with its cutting-edge technology and advanced features. In this blog post, we’ll dive into the world of Delcam Powermill and explore its capabilities, benefits, and success stories in the industry.

Efficient Machining with Delcam Powermill

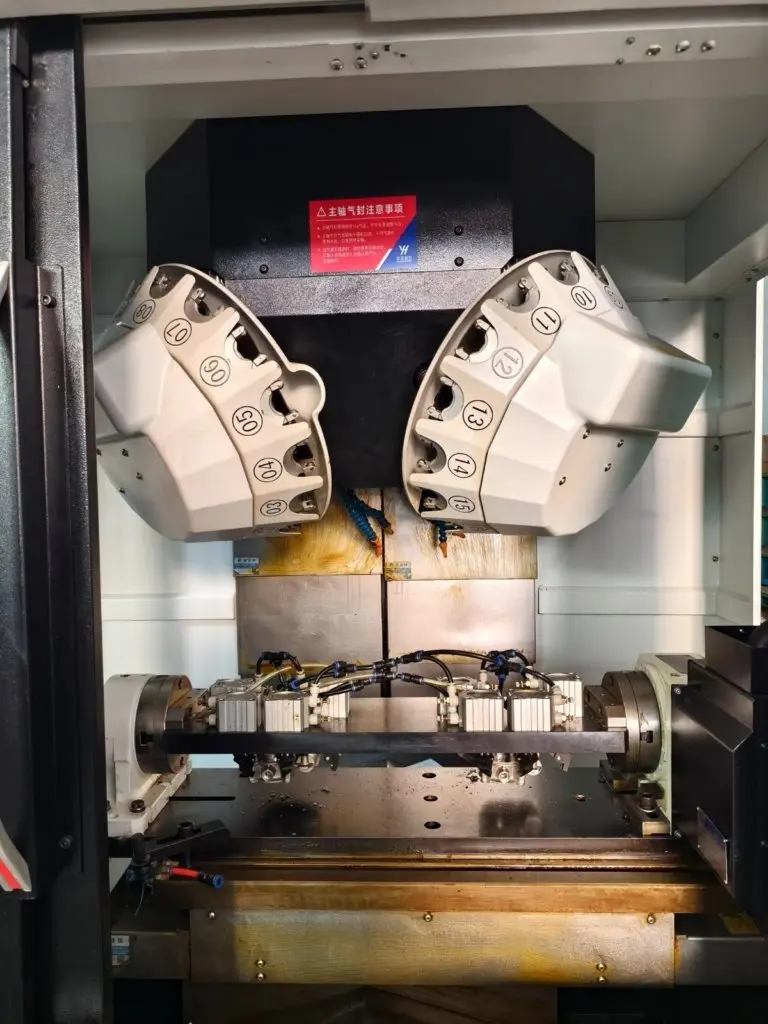

Delcam Powermill is an independent cam system that empowers users to unlock the full potential of their machine tools. Its latest machining strategy, featuring 5-axis machining, fast gross machining, and high-speed finishing, generates optimal machining paths, ensuring maximum machine utilization and minimizing production time. With Delcam Powermill, users can efficiently create complex parts with precision and accuracy.

Simulation and Automation

Delcam Powermill’s advanced simulation technology enables users to replicate the actual cutting process, simulating the treatment and cutting of entities. This innovative approach saves time and reduces costs by minimizing the need for physical testing and iterations. Additionally, the system’s automatic 5-axis machine avoidance function ensures the safety of your machine tools and parts.

Seamless Integration with CAD Systems

Delcam Powermill’s worry-free data exchange capabilities seamlessly integrate with various CAD systems, including Iges, STEP, VDA, and STL. This means that users can easily import and export data from a wide range of systems, streamlining their workflow and reducing errors.

Industry-Leading Features and Success Stories

Delcam Powermill has been adopted by numerous prominent companies, including the Chinese aviation industry’s Panhua Aviation Instrument and Electrical Factory. The company’s efficient processing strategy has repeatedly been implemented, resulting in significant productivity gains. Furthermore, Yanfeng Visteon Auto Parts Systems Co., Ltd. has purchased multiple Delcam software and module sets, utilizing them for design, electrode design, and 3-axis and 5-axis machining.

Some of the world’s top companies, including Faw Group, Dongfeng Motor Group, Shanghai Volkswagen, Harbin Electric, and Gree Electric, as well as global leaders such as Boeing, Toyota, GM, Ford, and Mercedes, have chosen Delcam Powermill as their preferred machining solution. This testament to Delcam’s innovative technology and professional services.

A New Era of Machining with Delcam Powermill

Delcam Powermill offers a comprehensive machining solution that meets the evolving needs of demanding industries. With its continuous improvement cycle, ensuring regular product updates and enhancements, Delcam Powermill empowers users to stay ahead of the curve.

Experience the Delcam Difference

Visit Delcam’s official website at delcam to discover more about the company’s cutting-edge technology and innovative products. With Delcam Powermill, the future of manufacturing is in your hands.