As a CNC machining center, we are committed to providing high-quality, precise and efficient processing services to meet the various needs of our customers. In this blog, we will take a closer look at the features and benefits of our five-axis CNC machining center, as well as the services we support our customers.

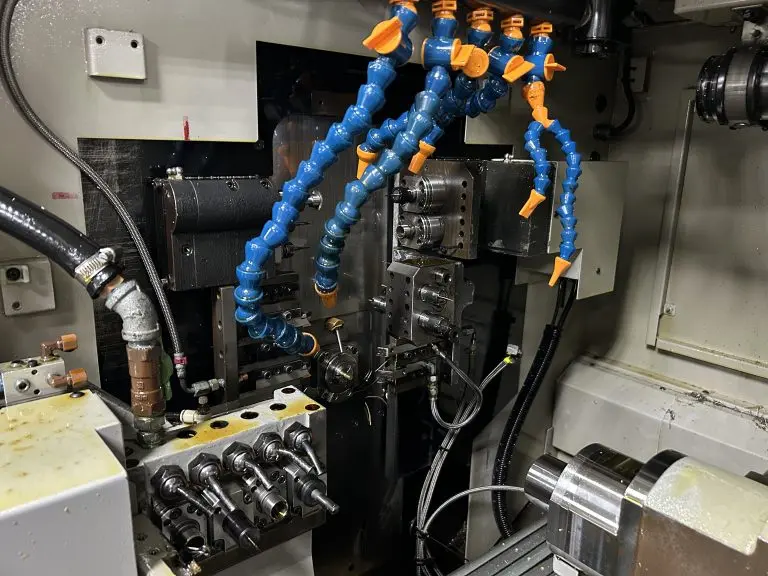

Our five-axis CNC machining centers are equipped with advanced technology including precision machining, high-speed processing and advanced metrology. This allows us to provide precise and efficient processing services to industries ranging from aerospace to automotive, medical, and oil and gas. With our state-of-the-art equipment, we can handle a variety of materials including aluminum, steel, titanium and more.

One of the key benefits of our five-axis CNC machining center is its ability to cut complex shapes and designs accurately and accurately. This is especially important in industries where precise tolerances are critical, such as aerospace and medical equipment. Our advanced CNC machining centers can handle complex tool and tool paths, allowing us to easily create complex shapes and designs.

In addition to our advanced technology, we also provide a range of value-added services including post-processing and completion. This includes processing, grinding, polishing and coating, etc. Our experienced team of engineers and technicians works closely with customers to design and implement customized solutions that meet their specific needs and exceed their expectations.

From an excellent perspective, we pride ourselves on our commitment to quality, precision and innovation. Our expertise in CNC machining enables us to provide high-quality parts that meet customers’ strict standards.

FAQ:

- What is five-axis CNC machining and how does it benefit my business?

Five-axis CNC machining is an accurate machining process that combines a combination of rotation and oscillation to create complex shapes and designs. This advanced technology enables us to create highly accurate and effective parts that meet customers’ strict standards.

- What types of materials can you use a five-axis CNC machining center to process?

We can handle a variety of materials including aluminum, steel, titanium, etc. Our expertise in CNC machining enables us to handle complex materials and provide high-quality parts that meet customer specific needs.

- Can you provide value-added services such as post-processing and completion?

Yes, we offer a range of value-added services including processing, grinding, polishing and coating. Our experienced team of engineers and technicians works closely with customers to design and implement customized solutions that meet their specific needs and exceed their expectations.

- How do you ensure quality and accuracy in CNC machining services?

From an excellent perspective, we pride ourselves on our commitment to quality, precision and innovation. Our experienced team of engineers and technicians works closely with customers to design and implement customized solutions that meet their specific needs and exceed their expectations. We also maintain a strict quality control program to ensure that all parts meet customers’ strict standards.

- How do I start with the CNC machining service at Great Light?

First, just email us or call us. Our team of experts will work with you to design and implement a custom solution to meet your specific needs and exceed your expectations. We look forward to serving you!