ABS, or Acrylonitrile Butadiene Styrene, is a thermoplastic polymer quite common in the industry, mainly known for its good impact resistance at low temperatures and its lightness. ABS plastic is also popular in the 3D printing market and is often compared to PLA. It is most commonly used in the FFF process, but it is also available in resin form, allowing it to be used in photopolymerization. In the guide below, we’ll take a closer look at ABS, including its production and performance, 3D printing processes, applications, major manufacturers, and pricing.

Production and characteristics of ABS

ABS was one of the first plastics used in industrial 3D printers, developed around 1990. This type of thermoplastic polymer is called a “terpolymer”, a polymer synthesized from three different monomers. In this case, it is usually obtained by polymerizing acrylonitrile and styrene in the presence of polybutadiene – usually 20% acrylonitrile, 25% butadiene and 55% styrene, hence the name ABS. Therefore, the properties of ABS can be modified by controlling these ratios; for example, styrene gives ABS rigidity and shine, while butadiene gives it impact resistance and low temperature properties.

ABS is a popular plastic in industry due to its properties (Photo credit: Adreco Plastics)

It is important to remember thatABS is made from petroleum, while PLA is made from natural resources such as corn starch. This often raises questions about sustainability in the industry, but ABS is actually recyclable, although it is not widely accepted by recycling centers. In terms of environmental concerns, this can be seen as an advantage because while PLA is technically biodegradable, it only does so under the right conditions, which raises the question of whether it is actually environmentally friendly.

In terms of performance,ABS plastic provides good rigidity and high impact resistance while remaining lightweight and affordable, making it a popular material in the 3D printing market. Additionally, it is resistant to chemicals and heat, making it ideal for more industrial applications, as we will see later in this article.

ABS plastic in 3D printing

As mentioned previously,ABS comes in filament and liquid resin forms – we’ll focus on the former. This thermoplastic is therefore available in filament form with a diameter of 1.75 mm or 2.85 mm and in a variety of colors. Although ABS is more difficult to print than PLA, it remains a material highly appreciated by 3D printing professionals due to its impact resistance and its resistance to high temperatures (-20°C to 80°C ). It is opaque, provides a smooth, shiny surface and can be chemically welded with acetone.

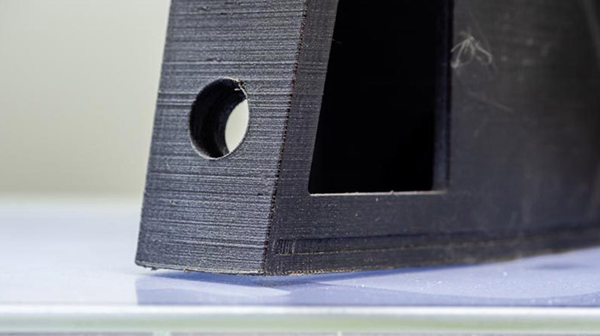

becauseThe melting temperature of ABS is approximately 200°C and extrusion temperatures between 230 and 260°C are recommended. Additionally, thermal printing should be usedplate(between 80 and 130°C). In fact, it is a plastic that shrinks in contact with air, so if it is not on a heated plate, it will deform and separate from the plate: this is called warping . For large parts, special adhesives such as Kapton or bonding paint are even recommended. Finally, it is recommended to use a 3D printer with a closed case for two reasons: on the one hand, for the safety of the user, because ABS plastic emits particles that can be dangerous for the user, but also because temperature control is crucial when working with ABS. To print successfully and avoid issues like tangling, cracking, and delamination (layer separation), a heated chamber helps maintain a consistent temperature.

Heating plates are required to prevent warping

althoughABS is more difficult to print than materials like PLA or PETG, but it is still easier to print than other inexpensive engineering thermoplastics. However, as mentioned earlier, controlling the temperature in the room, on the bed, or even the entire room is crucial to avoiding print failures. Also keep in mind that ABS is a material that must be kept dry because it absorbs moisture from the air, which will make printing more difficult.

Regarding the written press,ABS can easily be printed with HIPS, a material with the same platen and extrusion temperatures. The material dissolves quickly in D-limonene, a lemon-based solvent.

Printing with this thermoplastic polymer requires virtually no post-processing overall, which is a key time-saving advantage in the production of complex parts. However, for those interested,ABS offers a variety of post-processing options. In addition to removing the supports already mentioned, it can also be painted thanks to its more matte finish. It is also easy to work with compared to other materials, for example it can be sanded or milled. Finally, a common way to post-process ABS is to smooth it with acetone vapor to achieve a smooth surface.

The main uses of ABS plastic

As we mentioned,One of the main advantages of ABS is that it is a more technical material. Its applications therefore also tend to be more industrial. For example, it is popular in injection molding. It is also present in household appliances, but also in boat hulls, decorative pieces, toys and of course the famous Lego bricks.

When it comes to additive manufacturing, other common uses include prototyping, gears, and even molds, as it withstands physical stress better than other filaments. Additionally, aside from its chemical and heat resistance, its electrically insulating properties also make it attractive to those looking to create enclosures for electrical components and automotive parts such as dashboards or bumpers. It is also ideal for outdoor applications as it will not warp in the sun or over time.

LEGO bricks made fromMade of ABS

Main manufacturers and material prices

Today, many manufacturers offer it in filament formABS plastic; Major suppliers include long-time supplier Stratasys, China’s Esun, UltiMaker, FormFutura, Innofil3D, etc. Available in many colors, the price varies from 15 to 60 euros depending on the brand.

Please note thatABS Additive-Laden Filaments: You can find ABS made from carbon fiber or aramid fiber (better known as Kevlar). For example, these fibers can reduce warping of ABS, providing greater precision. Carbon alone improves the initial mechanical properties of the material. These high-tech materials are generally more expensive and have different printing parameters.

Source: 3dnatives

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.