Understanding the CNC Lathe Machine: The Cornerstone of Modern Precision Turning

In the realm of precision manufacturing, where the symphony of cutting tools and spinning workpieces creates the components that power our world, one machine stands as a foundational pillar: the CNC lathe machine. For engineers, designers, and procurement specialists seeking reliable, high-volume, and exceptionally accurate turned parts, grasping the capabilities and nuances of the CNC lathe is not just beneficial—it’s essential for making informed sourcing decisions.

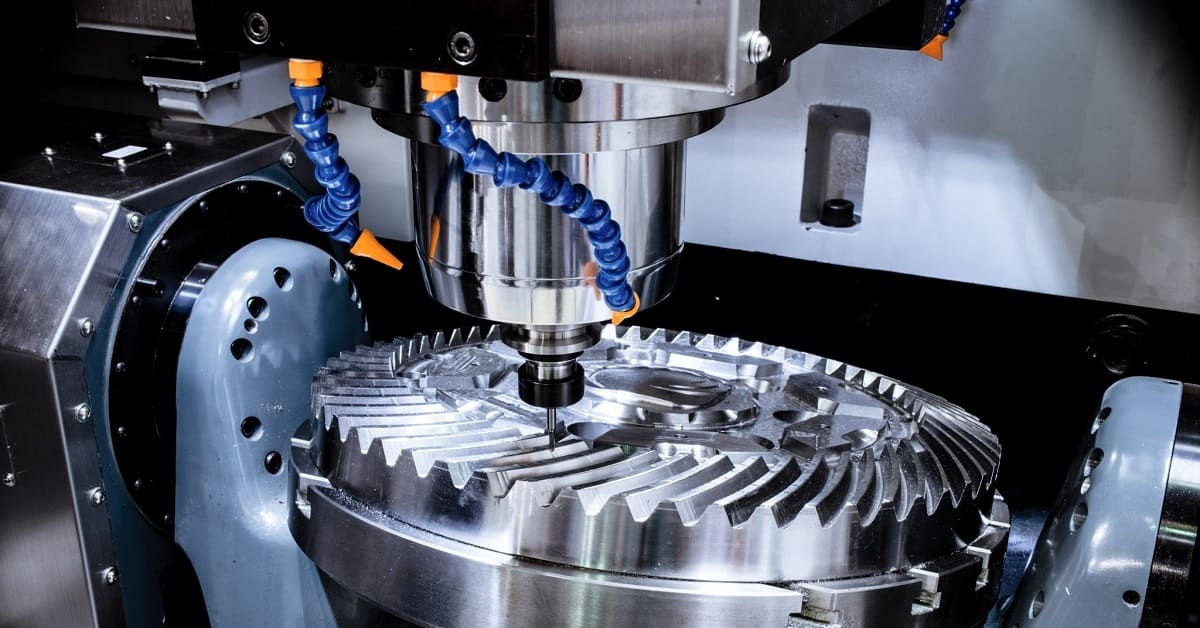

A CNC lathe machine is a computer-numerically-controlled machine tool that rotates a workpiece on a spindle while a stationary cutting tool is fed into it to remove material, shaping it into a desired cylindrical form. This process, known as turning, is fundamental for producing parts with rotational symmetry—think shafts, pins, bushings, connectors, and nozzles. Unlike its manual predecessor, the CNC (Computer Numerical Control) aspect translates a digital blueprint (CAD model) directly into precise mechanical movements, ensuring unparalleled repeatability and complexity in the finished parts.

The Evolution and Core Mechanics

The journey from simple manual lathes to today’s sophisticated CNC lathes mirrors the evolution of precision manufacturing itself. Early machinists relied on skill and handwheels; today, engineers program tool paths with tolerances measured in microns. At the heart of a modern CNC lathe are several key components:

The Spindle: The powerhouse that rotates the workpiece (or the chuck holding it) at precisely controlled speeds, often exceeding 10,000 RPM for high-speed machining.

The Tool Turret: A multi-station carousel that holds various cutting tools (turning tools, drills, boring bars, threading tools). It can automatically index to bring the correct tool into position, enabling complex operations in a single setup.

The Control System (CNC Controller): The “brain” of the machine. It interprets G-code instructions and governs the movement of axes (typically X and Z), spindle speed, feed rate, and coolant flow.

Bed and Slideways: Provide the rigid, stable foundation crucial for maintaining precision by minimizing vibration and deflection during cutting.

This orchestration of components allows a CNC lathe machine to perform operations far beyond simple external turning, including facing, grooving, parting, threading (internal and external), drilling, and boring.

Materials, Applications, and Why Precision Matters

The versatility of the CNC lathe machine is evident in the breadth of materials it can masterfully shape:

Metals: Aluminum, Stainless Steel (303, 304, 316), Brass, Copper, Titanium, Alloy Steel.

Plastics: PEEK, Delrin (Acetal), Nylon, PTFE.

Exotic Alloys: Inconel, Hastelloy.

This material adaptability translates into indispensable applications across critical industries:

Automotive: Engine components (valve stems, pistons), transmission parts, wheel hubs, and sensor housings.

Aerospace: Lightweight aluminum fittings, durable titanium fasteners, and high-strength landing gear components.

Medical: Precision surgical instrument handles, implantable device housings, and diagnostic equipment parts requiring biocompatible materials and flawless surface finishes.

Electronics: Connector pins, heat sink bases, and semiconductor equipment parts.

Industrial Machinery: Hydraulic cylinder rods, pump shafts, and bearing housings.

In these contexts, precision is non-negotiable. A deviation of a few microns in a fuel injector nozzle or a medical implant can lead to systemic failure or patient risk. This is where the true value of an advanced CNC lathe machine, operated within a rigorous quality management system, becomes clear.

CNC Lathe vs. CNC Mill: Choosing the Right Process

A common point of confusion is the distinction between a lathe and a mill. The fundamental difference is in the movement:

CNC Lathe (Turning): The workpiece rotates, and the cutting tool moves in linear axes. Ideal for creating rotationally symmetrical parts.

CNC Mill (Milling): The cutting tool rotates, and the workpiece is stationary or moves on linear axes. Ideal for creating complex 3D contours, pockets, and flat features.

For parts like a simple spacer or a bolt, a lathe is the obvious and most efficient choice. For a complex bracket with multiple angled holes and pockets, a mill is required. Many advanced workshops, like GreatLight Metal, seamlessly integrate both technologies, often using mill-turn centers (CNC lathes with live tooling and Y-axis) to complete complex parts in a single, efficient setup, reducing handling errors and lead times.

The GreatLight Metal Advantage in CNC Turning

When sourcing turned parts, partnering with a manufacturer that views the CNC lathe machine as part of an integrated solution, rather than just a standalone tool, is critical. This is where the approach of GreatLight Metal distinguishes itself.

Beyond the Machine: A System of Precision

At GreatLight Metal, the CNC lathe machine is the starting point of a guaranteed precision chain. The company’s investment in high-precision, rigid-turning centers from reputable manufacturers ensures the machine’s innate capability. However, the real differentiator lies in what surrounds the machine:

Pre-Process Engineering Support: Engineers analyze part designs for manufacturability (DFM), suggesting optimizations for tool accessibility, material selection, and tolerance stack-ups to enhance reliability and reduce cost.

In-Process Quality Assurance: Advanced probing systems on the machines themselves allow for on-the-fly tool wear compensation and first-article verification without removing the part.

Post-Process Metrology: A dedicated quality lab equipped with coordinate measuring machines (CMMs), optical comparators, and surface roughness testers provides documented, certifiable proof that every batch meets print specifications.

Trust Built on Certifiable Standards

For clients in regulated industries, the machine’s output is only as trustworthy as the system that governs it. GreatLight Metal operates under a framework of internationally recognized certifications:

ISO 9001:2015: The bedrock of a systematic quality management approach, ensuring consistency and continuous improvement.

IATF 16949: The automotive industry’s stringent quality standard, crucial for any supplier of turned automotive components, from prototypes to production runs.

ISO 13485: For medical device manufacturing, this certification validates the controlled, traceable, and hygienic processes necessary for medical-grade turned parts.

This certification matrix is not merely for display; it is an operational blueprint that guarantees every component produced on their CNC lathe machines, whether for a humanoid robot’s actuator or an aerospace fluid coupling, adheres to the highest global standards.

Conclusion

A CNC lathe machine is far more than a piece of factory equipment; it is a precision instrument that transforms raw material into the reliable, high-performance components that drive innovation. The choice of manufacturing partner for your turned parts should hinge not just on their possession of these machines, but on the depth of engineering expertise, the robustness of quality systems, and the integrity of processes that guide their operation. In a landscape where precision, reliability, and speed are paramount, selecting a partner with a proven track record and a holistic, system-driven approach to CNC lathe machining is the most strategic decision you can make for your project’s success.

Frequently Asked Questions (FAQ)

Q1: What tolerances can a standard CNC lathe typically hold?

A: Modern precision CNC lathes, under stable environmental conditions and with proper tooling, can consistently hold dimensional tolerances of ±0.01mm (±0.0004″) for standard production. For critical features, experienced manufacturers like GreatLight Metal can achieve tolerances as tight as ±0.005mm (±0.0002″) or better, depending on the part size and material.

Q2: When should I choose a CNC lathe over a 3D printer for metal parts?

A: Choose a CNC lathe machine for: 1) High-volume production (it’s faster and more cost-effective per part), 2) Superior material properties (wrought material strength vs. sintered), 3) Excellent surface finishes directly off the machine, and 4) Very tight tolerances on concentricity and diameters. 3D printing is better for ultra-complex internal geometries, one-off prototypes where tooling cost is prohibitive, or parts made from materials difficult to machine.

Q3: What is “live tooling” on a CNC lathe, and why is it important?

A: Live tooling refers to powered tools (like drills or end mills) mounted on the lathe’s turret. They can rotate and perform milling, drilling, or tapping operations while the workpiece is stationary or rotating. This “done-in-one” capability eliminates secondary operations on a separate milling machine, reducing setup time, handling, and potential alignment errors, significantly boosting efficiency for complex turned parts.

Q4: How do I ensure the consistency of my turned parts across large production runs?

A: Consistency is ensured by a combination of: 1) Machine rigidity and thermal stability, 2) Automated in-process probing for tool wear monitoring, 3) Statistical Process Control (SPC) where key dimensions are sampled and tracked throughout the run, and 4) a robust Quality Management System (like ISO 9001). Reputable suppliers will have protocols for all these areas.

Q5: My part design has a very thin wall section. Can it be machined on a lathe?

A: Machining thin walls is challenging due to vibration and deflection. It requires expert strategy: using sharp, positive-rake tools; optimizing speeds and feeds; employing steady rests or custom fixtures for support; and sometimes a sequence of roughing and finishing passes. An experienced engineering team is crucial to evaluate the feasibility and recommend design modifications if necessary to ensure success.