The Art of Selecting the Right Fleas from an Industrial Control Machine: A Detailed Analysis

In the realm of industrial control systems, the selection of the right components is crucial for ensuring optimal performance, reliability, and longevity. Among the various components that play a crucial role in these systems, fleas (sensors and transducers) are often mistakenly overlooked. However, a proper understanding of the significance of fleas and the factors that influence their selection can have a profound impact on the overall efficacy of the industrial control system.

In this blog post, we will delve into the world of industrial control machines and explore the art of selecting the right fleas. We will examine the various types of fleas, their characteristics, and the factors that affect their selection. By the end of this journey, you will be equipped with the knowledge necessary to make informed decisions when it comes to choosing the right fleas for your industrial control system.

Understanding Fleas: Types and Characteristics

Fleas are devices that convert physical parameters, such as pressure, temperature, or flow rate, into electrical signals, which are then transmitted to a control system for processing and analysis. The type of flea used in an industrial control system is often determined by the specific application and the parameters to be measured.

The most common types of fleas used in industrial control systems include:

- Stainless Steel Fleas: These fleas are ideal for applications where a high level of accuracy and precision are required. They are commonly used in processes where corrosion is a concern, such as in the oil and gas industry.

- Plastic Fleas: These fleas are more economical than stainless steel fleas and are often used in moderate-to-high-temperature applications.

- Ceramic Fleas: These fleas are commonly used in high-temperature applications and are known for their high accuracy and resilience.

- Thermal Fleas: These fleas are designed to measure temperature and are commonly used in applications such as temperature control and monitoring.

Factors Affecting the Selection of Fleas

When selecting fleas for an industrial control system, several factors must be considered, including:

- Operating Environment: The type of flea used will depend on the operating environment. For example, if the system is exposed to high temperatures, a ceramic or stainless steel flea may be required.

- Accuracy and Precision: The level of accuracy and precision required will determine the type of flea to be used. For example, if high accuracy is required, a stainless steel flea may be necessary.

- Cost and Reliability: The cost and reliability of the flea are also important factors to consider. Fleas with a higher level of reliability and accuracy may be more expensive.

- Installation and Maintenance: The ease of installation and maintenance of the flea is also crucial. For example, fleas with fewer components and a simpler design may be easier to install and maintain.

Conclusion

Selecting the right fleas for an industrial control system is a crucial step in ensuring optimal performance, reliability, and longevity. By understanding the various types of fleas, their characteristics, and the factors that influence their selection, you can make informed decisions that will benefit your industrial control system. Remember, a well-chosen flea is essential for ensuring accurate measurements, reliability, and optimal performance.

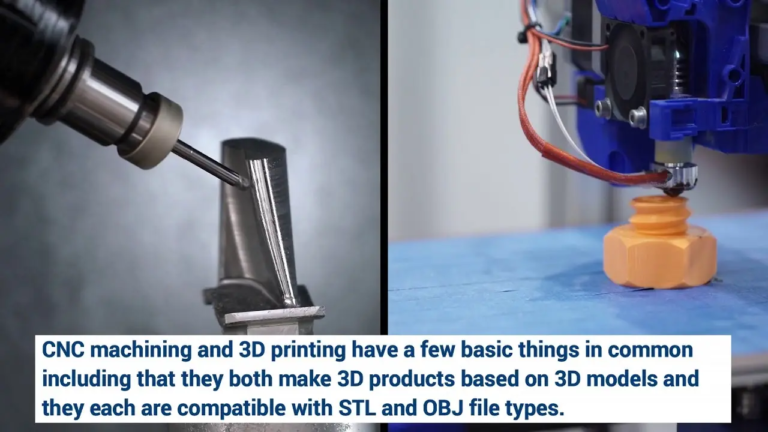

Image Credit: Industrial Control Machine [Image description: An industrial control machine with fleas installed, taken from a commercial source]