CNC (computer numerical control) machining is a revolutionary technology that has changed the face of manufacturing and manufacturing. This advanced method uses computer software to control machine tools to manufacture complex parts with unparalleled precision. This guide is intended to provide a comprehensive overview of CNC machining services, its applications, benefits, and the various principles behind the method.

Learn about CNC machining

What is CNC machining?

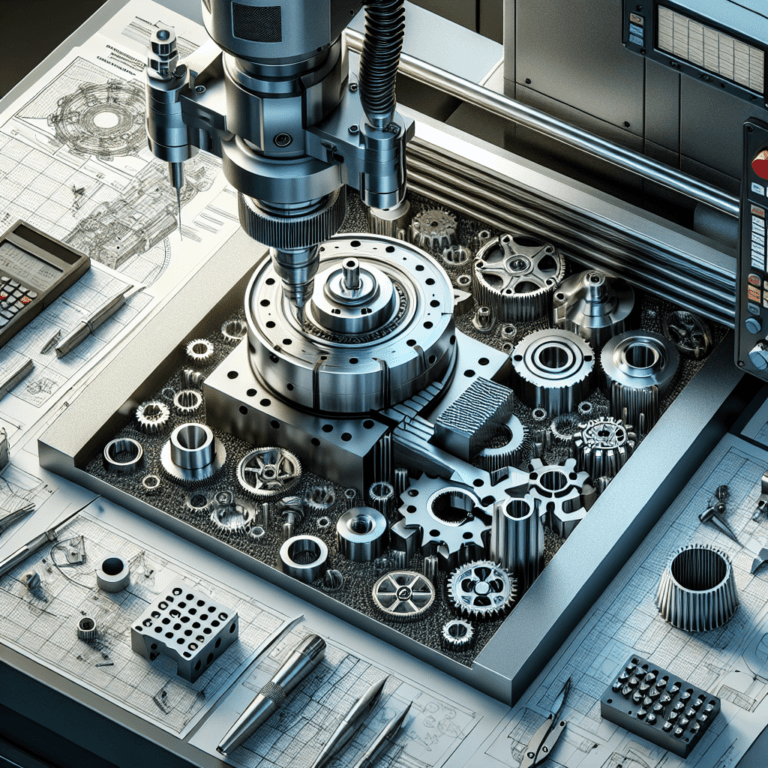

CNC machining is a process in which computer programs control the movement of factory tools and machinery. The process is used to create precision parts through subtractive manufacturing, which involves cutting material from a solid block to achieve the desired shape. The four main types of CNC machining processes include milling, turning, drilling and electrical discharge machining (EDM).

Basic knowledge: How CNC machining works

CNC machining begins with a digital 3D design, typically created using CAD (computer-aided design) software. Once the design is complete, it is converted into a CNC program using CAM (computer-aided manufacturing) software. The program is fed into the CNC machine, which interprets the commands and controls the tools to create the part.

Step by step process:

design creation: CAD software creates detailed digital representations of parts.

program conversion: CAD files are translated into G-code, a language that the CNC machine understands.

set up: The CNC machine is ready, including loading the material and holding it securely.

processing: CNC machines execute programs to carve parts using tools such as drills and milling machines.

- finishing: After machining, parts may require additional finishing processes such as grinding, polishing or coating to improve surface quality.

Types of CNC machine tools

CNC machining consists of a variety of machines, each designed for a specific application:

- CNC milling machine: Use a rotary cutting tool to remove material from a block. Great for complex geometries.

- CNC lathe: Rotates the workpiece by means of a fixed cutting tool, making it ideal for cylindrical parts.

- CNC milling machine: Effective for cutting softer materials such as wood and plastic.

- CNC plasma cutting machine: Use a plasma torch to cut conductive materials.

- CNC laser: Uses a focused laser beam to cut or engrave materials with high precision.

CNC machining applications

CNC machining is used across a wide range of industries due to its versatility and unparalleled precision. Here are some noteworthy applications:

aerospace industry

In aerospace, accuracy is non-negotiable. CNC machining is widely used to manufacture components such as brackets, accessories and other parts that must meet strict regulatory standards.

Automotive industry

From engine blocks to custom automotive parts, CNC machining enables high-quality parts to be produced at scale, ensuring optimal performance and safety.

medical device

CNC machining produces biocompatible prototypes, surgical tools, and implants with incredible precision that is critical to successful surgical outcomes.

electronic products

The electronics industry relies on CNC machining to manufacture housings, circuit boards and complex connectors, where micron-level precision is critical.

defense

CNC machining produces critical components used in weapons systems, vehicle parts and other defense applications, requiring the highest precision and reliability.

Benefits of CNC Machining Services

1. High precision and accuracy

One of the most significant advantages of CNC machining is the ability to produce parts with extremely high precision. This capability is critical in a field where even small deviations can lead to catastrophic failure.

2. Repeatability

CNC machines can reproduce the same part multiple times with the same accuracy. This repeatability is critical for large-scale production, where consistency is critical.

3. Improve efficiency

CNC machining automates the manufacturing process, reducing the time required to produce parts. Reduce manual intervention and significantly improve production efficiency.

4. Design flexibility

CNC machining allows manufacturers to easily switch between designs or create custom components without extensive re-machining. This flexibility is especially beneficial for industries that require rapid prototyping.

5. Cost-effective production

While the initial investment in CNC machinery can be significant, the long-term savings through reduced labor costs, minimized waste, and faster cycle times often justify the expense.

6. Material range

CNC processing supports a variety of materials, including metals (aluminum, steel, titanium), plastics (PVC, polycarbonate) and composite materials, to meet the needs of different industries.

7. Reduce waste

Subtractive manufacturing through CNC machining often results in less waste than traditional manufacturing methods, making it a more environmentally friendly option.

Choose the right CNC machining service

When looking for a CNC machining service provider, here are a few factors you should consider to ensure you get the best service for your needs:

1. Professional knowledge and experience

Find a supplier with a proven track record in CNC machining for your specific industry. Their ability to meet high standards of precision and quality control is critical.

2. Technology and equipment

Make sure their CNC machinery is up to date and capable of meeting the specific requirements of your project. Advanced machines with enhanced capabilities can provide you with clear advantages.

3. Prototyping and design support

A good CNC service provider will often provide design and prototyping support to ensure your design translates well into a manufacturable product.

4. Quality assurance

Look for certifications such as ISO 9001 or AS9100, which demonstrate our commitment to quality standards in our manufacturing processes.

5. Cost transparency

Get a detailed quote for a breakdown of costs. This transparency helps you make informed decisions and avoid hidden fees.

6. Customer Service

Evaluate the responsiveness and support of potential service providers. A good line of communication is critical for timely troubleshooting and problem resolution.

7. Turnaround time

Compare the turnaround times of different service providers. If you have a tight project deadline, make sure the provider you choose can meet the requirements without compromising on quality.

Innovation in CNC machining technology

The world of CNC machining continues to evolve, with numerous innovations designed to improve performance, efficiency, and precision. Here are some of the notable advancements shaping the industry.

1. Additive Manufacturing Integration

The convergence of CNC machining and additive manufacturing (3D printing) opens up new ways to produce complex and lightweight parts. Using CNC machines to finish 3D printed parts improves their dimensional accuracy.

2. IoT and predictive maintenance

Integrating IoT (Internet of Things) into CNC machines enables real-time monitoring of machine performance. This type of predictive maintenance can significantly reduce downtime by identifying potential issues before they escalate.

3.Advanced materials

Research into advanced materials such as carbon fiber composites and high-strength alloys combined with CNC machining technology can produce lighter and stronger parts, particularly beneficial for aerospace and automotive applications.

4. Artificial intelligence in CNC machining

Artificial intelligence (AI) is starting to play a role in optimizing machining processes by predicting the most efficient tool paths, automating tool changes, and improving overall process efficiency.

5. Multi-axis machining

The advent of multi-axis CNC machines can efficiently machine complex geometries in a single setup, greatly reducing the need for multiple setups and associated labor.

6. Virtual Reality (VR) for Simulation

Using VR during the design phase enables manufacturers to simulate machining processes, identify potential errors and plan efficient workflows before actual production begins.

in conclusion

CNC machining services provide unparalleled precision, efficiency and flexibility to a variety of industries, from aerospace and automotive to electronics and medical devices. As technology continues to develop, the future of CNC machining is expected to bring greater innovation, making it an indispensable process in modern manufacturing systems.

CNC Machining Services FAQs

Q1: What materials can be used for CNC processing?

A1: CNC machining can process a variety of materials, including metals (such as aluminum, steel, and titanium), plastics (such as PVC and nylon), and composite materials.

Q2: How does CNC machining compare to 3D printing?

A2: CNC machining is a subtractive manufacturing process, while 3D printing is an additive manufacturing process. CNC allows for high precision and is often the first choice for high-strength parts, while 3D printing excels at producing complex designs quickly.

Q3: What is the typical lead time for CNC machining services?

A3: Delivery times can vary significantly depending on the complexity of the part and the capabilities of the service provider. Typically, delivery time can vary from a few days to a few weeks.

Q4: Can CNC machining produce extremely complex parts?

A4: Yes, CNC machines are capable of producing highly complex parts, especially with multi-axis capabilities that allow for complex designs and functionality.

Q5: How to ensure the quality of CNC processing?

A5: Look for a service provider with ISO certification, robust quality assurance protocols, and application-specific experience to ensure high-quality results.

By understanding the complexities of CNC machining, companies can leverage this technology to increase production capabilities and remain competitive in a rapidly evolving market. Whether you’re looking for high precision or rapid prototyping, exploring CNC machining services can open the door to innovative manufacturing solutions.

keywords: CNC machining, precision parts, manufacturing, CAD, CAM, aerospace, automotive, medical equipment, computer numerical control, machining technology, advanced materials, multi-axis machining.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.