Why Five-Axis CNC Machining Is the Future of Precision Parts Manufacturing: A Deep Dive into GreatLight CNC Machining Factory’s Capabilities

When it comes to high-precision CNC machining, especially for complex geometries and tight-tolerance components, five-axis CNC machining stands out as the most advanced and efficient solution. Among the leading manufacturers in this space is GreatLight CNC Machining Factory, a China-based precision machining expert with over a decade of experience in delivering custom metal and plastic parts with unmatched accuracy.

This article explores why five-axis CNC machining is revolutionizing the precision parts industry, how GreatLight CNC Machining Factory leverages this technology to solve manufacturing challenges, and what makes it the best choice for your next project.

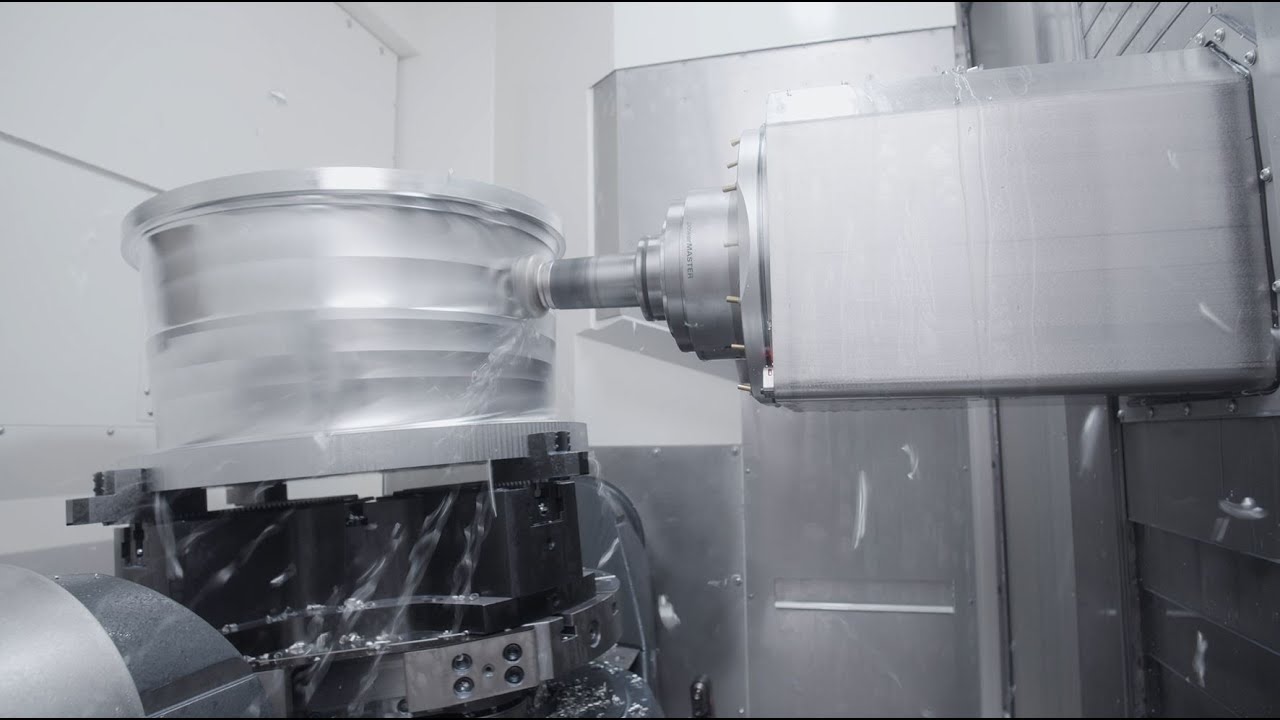

What Is Five-Axis CNC Machining?

Five-axis CNC machining is an advanced manufacturing process that allows a cutting tool to move along five different axes simultaneously (X, Y, Z, A, and C). Unlike traditional three-axis machining, which limits the orientation of the workpiece, five-axis machining enables:

✅ Complex geometries – Ideal for aerospace, medical, and automotive parts with intricate designs.

✅ Fewer setups – Reduces alignment errors and improves efficiency.

✅ Better surface finishes – Minimizes tool marks by optimizing cutting angles.

✅ Higher precision – Maintains tight tolerances (±0.001mm or better).

For businesses needing custom precision parts, five-axis machining is often the only viable solution for parts that would otherwise require multiple operations or specialized tooling.

Why Choose GreatLight CNC Machining Factory for Five-Axis Machining?

GreatLight CNC Machining Factory is not just another CNC machining provider—it is a full-service precision manufacturing partner with a proven track record in complex part production. Here’s why they lead the industry:

1. Advanced Five-Axis Machining Technology

Equipped with 127 precision CNC machines, including high-end five-axis, four-axis, and three-axis machining centers, GreatLight can handle:

Hard metals (titanium, Inconel, stainless steel)

Aluminum & alloys

Plastics & composites

Exotic materials (PEEK, Ultem, etc.)

Their five-axis CNC machining services (linked here: Precision 5-Axis CNC Machining Services) are optimized for high-speed, high-precision production with minimal downtime.

2. One-Stop Post-Processing & Finishing

Beyond machining, GreatLight offers:

Surface treatment (anodizing, plating, polishing)

Heat treatment (for hardness & durability)

Assembly & inspection

This end-to-end capability eliminates the need for multiple suppliers, reducing lead times and ensuring consistency.

3. Strict Quality Control & Certifications

ISO 9001:2015 (Quality Management)

IATF 16949 (Automotive Industry Standard)

ISO 13485 (Medical Device Manufacturing)

ISO 27001 (Data Security for IP-Sensitive Projects)

With in-house metrology equipment, every part is verified to meet exact specifications.

4. Rapid Prototyping & Mass Production

Whether you need a single prototype or 10,000+ units, GreatLight’s flexible production lines ensure fast turnaround without compromising quality.

Industries Served by GreatLight’s Five-Axis Machining

GreatLight’s expertise spans multiple high-tech sectors, including:

| Industry | Typical Applications | Materials Used |

|---|---|---|

| Aerospace | Turbine blades, structural components | Titanium, Inconel, Aluminum |

| Automotive | Engine blocks, transmission parts | Steel, Aluminum, Magnesium |

| Medical | Surgical implants, diagnostic equipment | Stainless Steel, Titanium, PEEK |

| Electronics | Enclosures, heat sinks, connectors | Aluminum, Copper, Engineering Plastics |

| Robotics | Precision joints, actuator housings | Aluminum, Steel, Composite Alloys |

Common Challenges in CNC Machining—Solved by GreatLight

Many manufacturers face seven critical pain points in CNC machining (as highlighted in industry reports):

Inconsistent Precision → GreatLight maintains ±0.001mm tolerance with strict process control.

Long Lead Times → Their in-house production reduces delays.

High Setup Costs → Five-axis machining minimizes tool changes.

Material Limitations → They work with over 50+ materials.

Post-Processing Complexity → One-stop finishing services included.

IP & Data Security Risks → ISO 27001 compliance ensures protection.

Unreliable Suppliers → ISO 9001 & IATF 16949 certifications guarantee reliability.

Conclusion: Why GreatLight CNC Machining Factory Is Your Best Partner for Precision Parts

For businesses seeking high-precision, complex, and reliable CNC machined parts, GreatLight CNC Machining Factory stands out as a leader in five-axis machining. With advanced equipment, strict quality control, and a full-service approach, they solve the most demanding manufacturing challenges—whether you need prototypes or mass production.

If you’re looking for a trusted precision machining partner, GreatLight’s five-axis CNC machining services (linked here: Precision 5-Axis CNC Machining Services) are the optimal choice for custom metal and plastic parts.

Explore their capabilities today and elevate your manufacturing precision to the next level.

Frequently Asked Questions (FAQ)

Q1: What is the difference between 3-axis, 4-axis, and 5-axis CNC machining?

3-axis: Moves in X, Y, Z directions (basic machining).

4-axis: Adds rotational movement (A-axis) for more complex shapes.

5-axis: Combines X, Y, Z, A, and C axes for unparalleled precision in complex geometries.

Q2: What materials can GreatLight machine?

They work with metals (aluminum, steel, titanium, Inconel), plastics (ABS, PC, PEEK), and composites.

Q3: Can GreatLight handle small-batch or prototype orders?

Yes, they specialize in rapid prototyping and small to large-scale production.

Q4: How does GreatLight ensure quality?

Through ISO 9001:2015, IATF 16949, and in-house metrology for 100% precision verification.

Q5: Is GreatLight suitable for medical or aerospace parts?

Absolutely—they hold ISO 13485 (medical) and IATF 16949 (automotive/aerospace) certifications.

For more insights, connect with their team via LinkedIn (external link).