The Evolution of CNC Mill-Turn Machining: An Indispensable Tool for Modern Manufacturing

In an era where efficiency and precision are paramount in manufacturing processes, CNC (Computer Numerical Control) machining stands as a marvel of modern engineering. Among the various advancements in this domain, CNC mill-turn machining has emerged as a versatile and indispensable technique for fabricating complex parts. This article delves into the intricacies of CNC mill-turn machining, its benefits, applications, and why it is a game-changer in the manufacturing landscape.

Understanding CNC Mill-Turn Machining

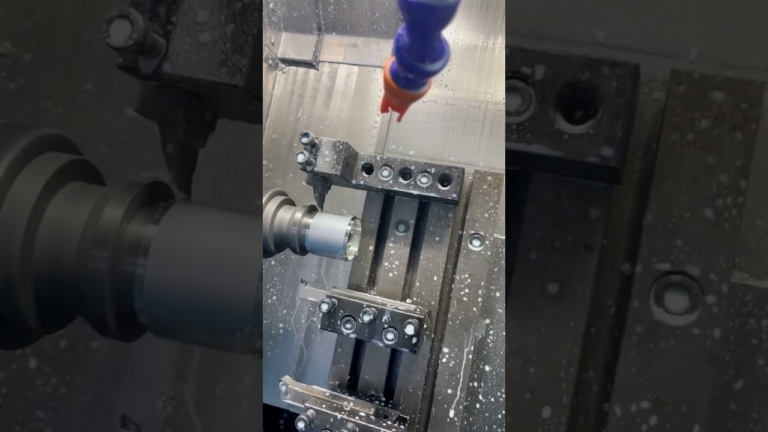

CNC mill-turn machining combines the functionalities of both milling and turning operations in a single setup, utilizing advanced CNC technology. Traditionally, milling and turning required separate machines, often leading to longer lead times and increased operational costs. With mill-turn machining, manufacturers can produce intricate components with varied geometries seamlessly. This integration leads to significant efficiency enhancements, allowing for reduced setup times and the elimination of potential errors that may arise during part transfers between machines.

The Mechanics Behind CNC Mill-Turn Machining

At its core, CNC mill-turn machining uses a CNC machine equipped with both a lathe and a milling spindle. This dual functionality allows for simultaneous operations, which can drastically shorten machining cycles. The machine’s computer controls all movements and operations, employing a G-code programming language to dictate the toolpath, spindle speed, feed rate, and more.

The process generally involves the following steps:

Inputting CAD Designs: Engineers create a 3D CAD model of the component, detailing specifications such as dimensions, tolerances, and surface finishes.

Generating Toolpaths: The CAD model is converted into G-code, allowing the CNC machine to understand how to move the tool across the material.

Material Setup: The raw material, often in the form of a round bar or block, is secured in the machine.

Machining Process: The CNC mill-turn machine executes the programmed toolpaths, performing milling operations on the exterior and turning operations on the interior, all in one continuous process.

- Finishing Touches: After machining, secondary processes, such as surface treatments or inspections, may be carried out.

Key Advantages of CNC Mill-Turn Machining

Increased Efficiency: One of the most significant benefits of CNC mill-turn machining is the reduction in machining time. By combining operations, manufacturers can cycle through parts more quickly, allowing them to meet tight production deadlines.

Improved Accuracy: The precision of CNC operations ensures that parts are manufactured to exact specifications. The single setup approach minimizes risks associated with transferring parts between machines.

Greater Flexibility: CNC mill-turn machines can handle various materials—metals, plastics, and composites—with ease. This versatility allows manufacturers to adapt to changing market demands without investing in additional machinery.

Complex Geometries: The integration of milling and turning enables the production of parts with highly intricate shapes and features, which would be difficult to achieve with conventional methods.

- Cost Efficiency: By reducing the number of setups, lowering labor costs, and minimizing waste through enhanced precision, CNC mill-turn machining can lead to considerable cost savings over time.

Applications of CNC Mill-Turn Machining

CNC mill-turn machining is utilized across a multitude of industries due to its adaptability and precision. Some of the prominent applications include:

Aerospace Engineering

In the aerospace sector, components often require both precision and lightweight materials. CNC mill-turn machining is used to manufacture parts such as turbine housings, brackets, and engine mounts, where accuracy is critical for safety and performance.

Automotive Manufacturing

The automotive industry frequently employs CNC mill-turn machining for producing engine components, transmission cases, and various bespoke parts. The ability to create complex geometries in a single setup is particularly advantageous in high-volume production.

Medical Devices

In medical manufacturing, where conformity to stringent regulations is vital, CNC mill-turn machining allows for the production of customized surgical tools, implants, and housings for medical devices. The precision achieved is crucial when dealing with components that must integrate seamlessly with human anatomy.

Oil and Gas

The oil and gas industry requires components that can withstand extreme conditions. CNC mill-turn machining is employed to fabricate valves, fittings, and other critical components that require both robustness and precision.

The Intersection of CNC and 5-Axis Technology

The advent of 5-axis CNC machining has further revolutionized mill-turn capabilities. In 5-axis CNC machining, the tool can move along five different axes simultaneously, allowing for even more complex shapes and angles to be machined accurately.

Advantages of 5-Axis Milling

- Enhanced Precision: 5-axis machining minimizes the need for resetting the workpiece, enhancing accuracy over the course of production runs.

- Complex Parts: Facilitates the creation of intricate geometries that would be impossible to machine effectively with traditional 3-axis milling.

- Reduced Setup Time: By allowing multiple sides of a part to be accessed without reorienting the part, manufacturers save time and increase efficiency.

Selecting the Right CNC Mill-Turn Machine

When considering investing in CNC mill-turn technology, manufacturers must evaluate several key factors:

- Size and Capacity: The machine should be selected based on the dimensions and weight of the materials typically processed.

- Precision Requirements: Different machines offer varying degrees of precision; investing in high-precision equipment is essential for critical applications.

- Software Compatibility: Ensure that the CNC machine is compatible with the CAD/CAM software in use, allowing seamless integration into existing workflows.

- Supplier Support: Evaluate the manufacturer’s reputation for service and support, as a reliable partner will be crucial for maintenance and troubleshooting.

The Future of CNC Mill-Turn Machining

As technology continues to evolve, the future of CNC mill-turn machining looks promising. Trends toward higher automation, artificial intelligence integration, and advancements in material science place CNC machining at the forefront of manufacturing innovation. Companies that invest in these technologies are likely to benefit from increased production capabilities, lower costs, and enhanced precision, securing their place in a competitive landscape.

Conclusion

CNC mill-turn machining represents a significant leap forward in manufacturing processes, marrying the efficiency of CNC technology with the versatility of dual operations. From aerospace to automotive and beyond, its applications are vast and varied, catering to industries that demand both precision and speed. As manufacturers embrace the benefits of this innovative technology, they pave the way for a more efficient and productive future in manufacturing. By understanding the mechanics, advantages, and applications of CNC mill-turn machining, stakeholders can make informed decisions that propel their operations into the next era of manufacturing excellence.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.