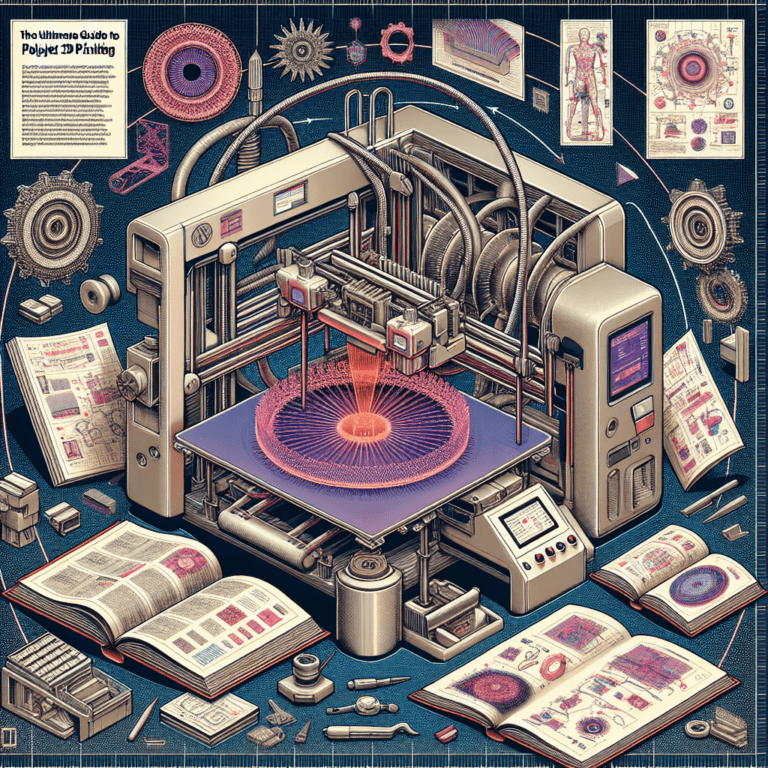

Understanding PolyJet 3D Printing

PolyJet 3D printing is an advanced additive manufacturing technology known for its ability to create highly detailed and complex models. This technique utilizes photopolymer resins, which are cured layer by layer through ultraviolet light. The process enables the production of parts with fine features, intricate geometries, and varying material properties—all within a single build.

How PolyJet 3D Printing Works

The PolyJet process begins with a digital 3D model, created through computer-aided design (CAD) software. The printer consists of multiple print heads, which jet microscopic droplets of liquid photopolymer resin onto a build platform. The printer moves in the X, Y, and Z axes, gradually building the part layer by layer. Once each layer of resin is applied, UV light is used to cure and harden the material, allowing subsequent layers to be added.

The result is a highly accurate and detailed part, with resolutions as fine as 16 microns. This technology supports various materials and colors, enabling the creation of prototypes, molds, and end-use parts.

The Key Advantages of PolyJet 3D Printing

PolyJet 3D printing boasts several benefits that make it a preferred choice for industries such as automotive, aerospace, healthcare, and consumer products.

1. High-Resolution Output

One of the standout features of PolyJet technology is its capability to produce incredibly fine details. The system delivers highly detailed prototypes, making it ideal for intricate designs, such as those needed in jewelry and dental applications. Manufacturers can achieve textures and features that would be difficult or impossible to replicate using traditional methods.

2. Material Versatility

PolyJet 3D printers can handle a wide variety of materials, including flexible, rigid, clear, and opaque finishes. Users can combine different materials in a single print to create components with varying properties, such as soft-touch surfaces or transparent windows. This flexibility enhances the functionality and aesthetic appeal of the final product.

3. Speed and Efficiency

PolyJet technology is designed for rapid prototyping. The ability to print multiple parts simultaneously reduces production times significantly. Additionally, since files can be adjusted digitally, designers do not need to create new molds or tooling to test different designs.

4. Multi-material Printing

PolyJet printers allow multi-material printing, where various materials can be incorporated into a single object during the printing process. This feature is particularly useful for applications that require different mechanical properties or colors in one component, such as for ergonomic grips or functional assemblies.

5. Cleaner Printing Process

PolyJet 3D printing utilizes liquid resins that are cured with UV light, resulting in minimal post-processing waste. Furthermore, the process produces fewer emissions compared to other technologies, such as Fused Deposition Modeling (FDM), which emits volatile organic compounds (VOCs) from heated plastics.

Applications of PolyJet 3D Printing

The versatility of PolyJet 3D printing has led to its adoption across various industries. Here are some notable applications:

Rapid Prototyping

Industries leverage PolyJet for rapid prototyping to expedite product development cycles. Designers can create accurate models that mimic the final product’s look and feel, allowing for thorough testing and iterations without the long lead times associated with traditional manufacturing processes.

Medical Devices

In the medical field, PolyJet technology is utilized to produce custom medical devices, surgical guides, and anatomical models. The detailed and biocompatible materials allow for realistic representations of human anatomy, enhancing educational tools and improving surgical planning.

Aerospace and Automotive

Both aerospace and automotive industries benefit from PolyJet’s lightweight and durable prototypes, enabling engineers to test components under real-world conditions without incurring heavy costs. Custom fixtures and tooling can also be quickly produced, reducing downtime and improving efficiency.

Consumer Products

From consumer electronics to sports equipment, PolyJet is used to create prototypes that evaluate design, functionality, and ergonomics. Brands can effectively gauge customer response to new products, make necessary adjustments, and ultimately go to market quicker.

Education and Research

Educational institutions utilize PolyJet technology to support innovation in engineering and design courses. 3D-printed models facilitate hands-on learning, enabling students to grasp complex concepts vividly.

Choosing the Right PolyJet Printer

Selecting the right PolyJet printer entails consideration of several critical factors:

Build Size

Different PolyJet printers offer varying maximum build dimensions. Consider the size of the components you intend to print and choose a machine that accommodates your requirements. Larger print beds can handle bigger parts or multiple components in a single batch.

Material Compatibility

Ensure the chosen printer supports the range of materials you plan to use. Some machines may specialize in flexible materials, while others offer a broader spectrum of rigid and colorful options.

Resolution and Quality

Resolution directly impacts the level of detail achievable in your prints. Higher resolution typically results in better quality, but can also increase print times. Identify the balance between quality and efficiency based on your project needs.

Budget

PolyJet printers can vary significantly in price. Assess your budget and ensure that the benefits of the selected printer align with your production goals. Consider both initial costs and the long-term operational costs associated with running the printer.

Post-Processing of PolyJet Parts

Although PolyJet parts are produced with high accuracy, some post-processing steps may enhance the final output:

Cleaning

After printing, parts may have residual support material or uncured resin. Washing the parts in a solvent or using a rinse station can remove these residues, improving surface finish and clarity.

Curing

While the layers are cured during the printing process, additional UV curing may enhance the mechanical properties and surface durability of the finished parts.

Painting and Finishing

For end-use parts, additional painting, polishing, or finishing can achieve the desired aesthetic quality. Some users may opt to apply coatings or finishes to improve UV resistance or to alter the visual characteristics of the printed model.

Conclusion

PolyJet 3D printing stands out as a leading technology for achieving rapid, high-resolution prototyping and manufacturing. Its versatility across materials and applications makes it a valuable solution for industries ranging from healthcare to automotive. By understanding the process, advantages, and best practices associated with PolyJet technology, businesses can harness its power to innovate and improve product development cycles.

Final Thoughts

As one of the most advanced 3D printing technologies available today, PolyJet continues to evolve, offering even more capabilities. Whether you are a manufacturer, designer, educator, or simply an enthusiast, exploring the potential of PolyJet can provide remarkable opportunities for creativity and efficiency in the world of additive manufacturing.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.