Understanding CNC Machining and Spiral Groove Milling

CNC machining is at the forefront of modern manufacturing, offering precision and efficiency that traditional machining methods often struggle to match. Among the various techniques employed in CNC machining, spiral groove milling stands out due to its capacity to create intricate shapes and features necessary for many applications. This article delves into the process of CNC machining, with a particular focus on spiral groove milling, its applications, benefits, and the technologies that underpin it.

What is CNC Machining?

CNC, or Computer Numerical Control machining, utilizes computer software to control machine tools for production. This technology has revolutionized the manufacturing industry by enabling high precision, repeatability, and the ability to create complex geometries that would be nearly impossible to achieve by hand. CNC machines can operate with various materials, including metals, plastics, and composites, making them versatile in different industries, from aerospace to medical equipment.

Advantages of CNC Machining

Accuracy and Precision: CNC machines can execute intricate designs with minimal human intervention, ensuring consistency across parts.

Repeatability: Once programmed, CNC machines can produce thousands of identical parts with exactly the same specifications, which is crucial for mass production.

Efficiency: CNC machining often involves less manual labor and shorter production times, leading to cost savings and faster turnaround times.

- Complexity: CNC milling, especially with advanced techniques like spiral groove milling, allows for the creation of complex and detailed shapes that enhance product functionality and aesthetics.

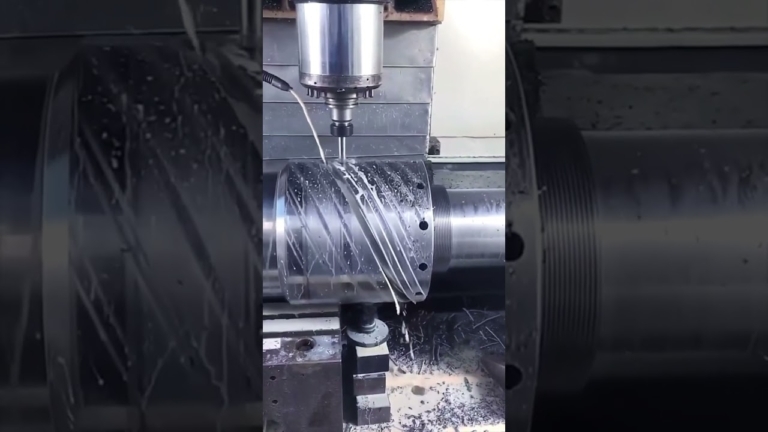

What is Spiral Groove Milling?

Spiral groove milling is a specialized form of milling that creates helical grooves or patterns on the surface of a workpiece. This technique is particularly useful for applications that require fluid flow, such as hydraulic components, or for aesthetic purposes in products like musical instruments and decorative elements.

The helical shape of the groove allows fluids to move smoothly, reducing turbulence and improving flow rates, which is critical in hydraulic and pneumatic systems. Additionally, spiral grooves can be employed to create threaded surfaces, enhancing grip and engagement for fasteners.

The Process of Spiral Groove Milling

Design and Planning: The first step in spiral groove milling is designing the groove’s geometry using CAD (Computer-Aided Design) software. The design phase incorporates all specifications, including depth, width, pitch of the groove, and material type.

Programming: Once the design is complete, it is converted into a CNC code, typically G-code, which instructs the CNC machine on how to create the desired geometry. This includes details about tool paths, feed rates, and cutting speeds.

Setup: The workpiece is secured to the CNC machine, ensuring that it is immobilized during the milling process. The appropriate cutting tool is selected to accommodate the dimensions and material of the workpiece.

Milling Process: The CNC machine carries out the milling process, removing material in a controlled manner to form the spiral groove according to the programmed specifications. The use of a 5-axis CNC machine allows for more intricate designs since it can move in multiple directions simultaneously.

- Inspection and Quality Control: After milling, the finished part undergoes thorough inspection. The dimensions are measured, and surface finishes are assessed to ensure they meet the required tolerances specified during the design process.

The Role of 5-Axis CNC Machining in Spiral Groove Milling

5-axis CNC machining represents the pinnacle of CNC technology, allowing for unparalleled versatility and capability in manufacturing. Unlike traditional 3-axis machines, which can only move along the X, Y, and Z axes, 5-axis machines can angle the tool and workpiece, providing access to the most complex geometries.

Benefits of 5-Axis CNC Machining

Complex Geometries: 5-axis machines can produce intricate designs, including spiral grooves, that would be difficult or impossible to achieve with 3-axis machines.

Better Surface Finish: The ability to approach the workpiece from multiple angles diminishes the number of setups and aids in achieving superior surface finishes.

Reduced Setup Times: Multi-sided machining capabilities reduce the need to reposition the workpiece, which contributes to faster turnaround times.

- Increased Tool Life: Due to better control of the cutting tool angles, 5-axis machining often results in less tool wear, increasing the overall lifespan of the tools used.

Applications of Spiral Groove Milling

Spiral groove milling is applicable in various industries, leveraging the unique geometries created by this technique for multiple uses.

Hydraulic Components

In hydraulic systems, spiral grooves are commonly used in pumps and valves to facilitate efficient fluid flow. The design helps reduce turbulence, resulting in smoother operation and increased efficiency.

Aerospace Industry

Components manufactured with spiral grooves can be crucial in aerospace applications, such as aircraft engines and landing gear. These grooves help manage airflow and reduce drag, leading to improved performance and safety.

Medical Devices

In the medical field, precision is paramount. Spiral grooves are often employed in devices like syringes and tubes, which require accurate flow regulation for effective patient care.

Automotive Sector

In automotive engineering, spiral groove milling can be used to manufacture parts that improve power efficiency and performance, such as air intake systems and exhaust components.

Decorative Applications

Aside from structural functionality, spiral grooves can serve aesthetic purposes in design elements. They enhance the visual appeal of consumer products, like musical instruments, luxury goods, and home decor items.

Challenges in Spiral Groove Milling

Despite its numerous benefits, spiral groove milling presents specific challenges that manufacturers must consider.

Tool Selection: Choosing the right tool for a specific material and groove design is critical. The wrong tool can lead to poor results or tool breakage.

Material Properties: Different materials respond uniquely to milling processes. Manufacturers must consider hardness, toughness, and other material properties to optimize the machining process.

- Programming Complexity: Creating the CNC program for intricate spiral designs can be complicated and time-consuming, requiring skilled personnel and advanced software.

Conclusion

CNC machining, especially through techniques like spiral groove milling, represents a significant advancement in the manufacturing industry. With benefits such as high precision, efficiency, and the ability to create complex geometries, spiral groove milling plays a pivotal role in various applications, from aerospace to medical devices.

As technology continues to advance, the future of CNC machining looks promising, with innovations like 5-axis machining further enhancing capabilities. By selecting the right tools and employing skilled operators, manufacturers can leverage spiral groove milling to produce high-quality components that meet the ever-growing demands of various industries.

As the industry evolves, embracing these advanced techniques will be essential for companies striving for excellence in product manufacturing. Whether for functional or aesthetic purposes, spiral groove milling is here to stay as an integral aspect of modern CNC machining.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.