Introduction to CNC Machining

In the rapidly evolving landscape of manufacturing and production, CNC machining has emerged as a game-changer, revolutionizing the way components are designed and fabricated. CNC, which stands for Computer Numerical Control, employs computers and sophisticated software to dictate the movement of machinery, allowing for an unprecedented level of precision and efficiency. This technology is instrumental in various sectors, particularly in the automobile industry, where the demand for intricate and high-quality parts is incessantly rising.

Understanding CNC Machining

CNC machining encompasses a range of processes that utilize computer-controlled equipment to produce complex geometries and specifications. Unlike traditional machining methods that rely on manual labor and simple tools, CNC machining allows for automation and consistency. This is particularly advantageous in industries where precision engineering is paramount.

The core of CNC machining involves converting a digital design (usually created in CAD software) into a machine-friendly format (G-code), which directs the machine on how to move. Machines integrated with CNC technology can include mills, lathes, routers, and grinders, among others.

Advantages of CNC Machining

Precision and Accuracy: One of the most significant advantages of CNC machining is its ability to produce highly accurate and precise parts consistently. The computer-controlled processes eliminate human error, ensuring that each part produced meets strict tolerances.

Complex Geometry: CNC machining can create intricate designs that would be nearly impossible to achieve through manual methods. This capability is crucial in sectors like automotive manufacturing, where components often have complex shapes and features.

Automation and Efficiency: CNC machines can operate continuously, producing parts without the need for constant human oversight. This leads to increased productivity and lower labor costs, making it an attractive option for manufacturers.

Flexibility in Production: CNC machining allows for quick adjustments and changes to designs, enabling manufacturers to adapt to evolving market demands and minimize downtime. This flexibility can be a critical competitive advantage.

- Material Versatility: CNC machining can work with a wide range of materials, including metals, plastics, and composites. This adaptability facilitates the creation of parts suited to various applications across different industries.

The Role of CNC Machining in the Automobile Industry

The automobile industry is one of the largest consumers of CNC machining. With the relentless push for innovation and improved performance, manufacturers are continually seeking efficient ways to produce high-quality components. CNC machining plays a pivotal role in this sector for several reasons:

1. Component Precision

Automobile manufacturing requires parts that fit together with extreme precision. CNC machining allows for the repetitive production of critical components such as engine blocks, transmission parts, and suspension systems, ensuring that they meet the exact specifications required for optimal performance.

2. Lightweighting

With the growing emphasis on fuel efficiency and sustainability, automobile manufacturers are increasingly focusing on lightweight materials. CNC machining enables the use of advanced materials and the creation of complex geometries that reduce weight without compromising strength or safety.

3. Rapid Prototyping

The automobile industry relies heavily on rapid prototyping for the design and testing of new models. CNC machining facilitates the swift production of prototypes, allowing engineers to test and iterate designs quickly before moving into full-scale production.

4. Customized Solutions

CNC machining is ideal for creating custom parts, which is essential in the production of specialized vehicles, performance upgrades, and aftermarket parts. This customization ability allows manufacturers to cater to niche markets while maintaining high-quality standards.

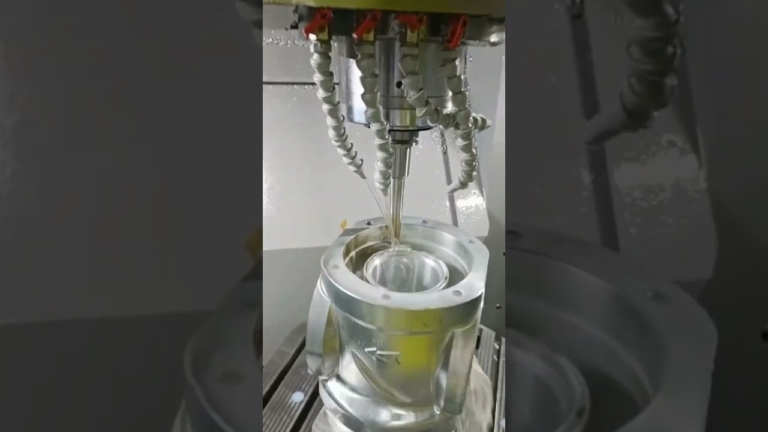

Exploring 5-Axis CNC Machining

Among the various types of CNC machining, 5-axis CNC machining stands out for its enhanced capabilities. Unlike traditional 3-axis machines that only move along three linear axes (X, Y, and Z), 5-axis machining incorporates two additional rotational axes. This advancement significantly enhances the ability to create intricate and complex parts.

Benefits of 5-Axis CNC Machining

Improved Accuracy: The increased degrees of freedom in a 5-axis setup allow for greater precision and reduced tooling time. This results in parts that require minimal post-processing or rework.

Enhanced Tool Life: With the ability to orient tools optimally, 5-axis machining reduces tool wear and increases their operational lifespan.

Efficient Machining: By addressing complex geometries in fewer setups, manufacturers can decrease production times and lower costs.

- Reduced Setup Time: Fewer setups mean less downtime, allowing for a smoother production flow and quicker turnaround times.

Key Considerations for Choosing CNC Machining

When selecting a CNC machining provider, several crucial factors should be considered to ensure the best fit for your project needs.

1. Experience and Expertise

Look for a machining service with a proven track record and experience in your specific industry. Expertise in working with the materials and specifications relevant to your project is essential for achieving the desired results.

2. Technology and Equipment

Evaluate the technology and equipment used by the CNC machining provider. Advanced machinery, such as 5-axis CNC machines, offers enhanced capabilities and efficiencies. Providers with up-to-date technology are more likely to deliver high-quality parts within shorter lead times.

3. Quality Assurance Processes

In industries like automotive, adhering to strict quality standards is non-negotiable. Ensure that the CNC machining provider has robust quality control processes in place, including inspections and certifications, to maintain the integrity of the parts produced.

4. Capacity and Lead Times

Consider the provider’s production capacity and lead times. Whether you’re looking for low-volume prototypes or large-scale production runs, the machinist’s ability to meet your timeline is critical.

5. Customer Support and Communication

Effective communication is vital throughout the design and production processes. Choose a CNC machining partner that prioritizes customer service, ensuring responsive communication and collaboration.

Conclusion

CNC machining is an indispensable technology that has transformed the manufacturing landscape, particularly in the automobile industry. With its ability to produce precise, complex, and customizable components, it empowers manufacturers to meet the growing demands of innovation and performance. As technology continues to advance, CNC machining will likely evolve further, incorporating artificial intelligence and other modern tools, ensuring its place at the forefront of manufacturing excellence.

By understanding the benefits, applications, and considerations associated with CNC machining, manufacturers can effectively harness its potential, significantly enhancing their production capabilities and overall competitiveness in today’s fast-paced market. Whether leveraging 3-axis or advanced 5-axis CNC technologies, the future of precision manufacturing appears bright and promising.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.