The Precision Behind Every Component: Demystifying CNC Precision Turning

In the intricate world of manufacturing, where even the smallest deviation can lead to catastrophic failure, precision is paramount. This is especially true when producing components that operate within the tight tolerances of aerospace engines, medical implants, or cutting-edge semiconductor equipment. Enter the realm of CNC Precision Turning – a cornerstone technology delivering the exacting specifications modern industry demands. This blog post delves into the process, benefits, applications, and why choosing the right partner like GreatLight makes all the difference.

What is CNC Precision Turning?

CNC Precision Turning is a sophisticated subtractive manufacturing process where a computer-controlled lathe rotates a metal or plastic workpiece against a stationary cutting tool. The machine systematically removes material to create cylindrical parts with precise diameters, lengths, complex geometries (like tapers, grooves, threads), and intricate features like shoulders or concentricity. The "CNC" stands for Computer Numerical Control, meaning the machine’s movements are dictated by a pre-programmed code generated from CAD (Computer-Aided Design) models. This eliminates manual operation variability and enables unparalleled consistency.

The Precision Advantage: Why CNC Turning Excels

- Unmatched Dimensional Accuracy & Tight Tolerances: CNC Turning achieves tolerances typically ranging from ±0.0001" to ±0.0002" (±0.002mm to ±0.005mm) or even tighter, depending on the material and setup. This level of accuracy is critical for parts that must fit perfectly and function reliably.

- Exceptional Surface Finish: The rotation of the workpiece against the cutting tool allows for smooth material removal. Combined with appropriate tooling and programming, CNC Turning can produce polished finishes (Ra ≤ 0.8µm) or specific surface textures required for applications like bearings or fluid dynamics.

- High Efficiency & Speed: Once the program is loaded, CNC Turning can run unattended for extended periods, significantly boosting throughput. It’s particularly efficient for producing large quantities of identical parts quickly.

- Complex Geometry Capability: Modern CNC Turning centers are incredibly versatile. Beyond simple cylinders, they can incorporate milling operations (turning + milling), drilling, tapping, knurling, grooving, and even threading complex features onto the workpiece, often in a single setup.

- Material Versatility: CNC Turning handles a vast array of materials with ease: steels (carbon, alloy, stainless), titanium, aluminum, brass, copper, various plastics, and even exotic materials like superalloys or specialized composites. This flexibility is vital for diverse industries.

The Journey From Design to Dimension: A Look at the Process

While specifics can vary, the core steps in CNC Precision Turning are:

- Design: The part starts as a 3D CAD model, meticulously designed to meet functional and dimensional requirements.

- Program Generation (CAM): Specialized software translates the CAD model into the precise toolpaths the CNC Turning machine needs to follow. This includes defining speeds, feeds, depths of cut, tool changes, and positioning.

- Machine Setup: The appropriate turning tool, often a solid carbide or ceramic insert, is mounted in the turret. The workpiece is securely held in the chuck or collet. Coolant is applied to lubricate and remove chips.

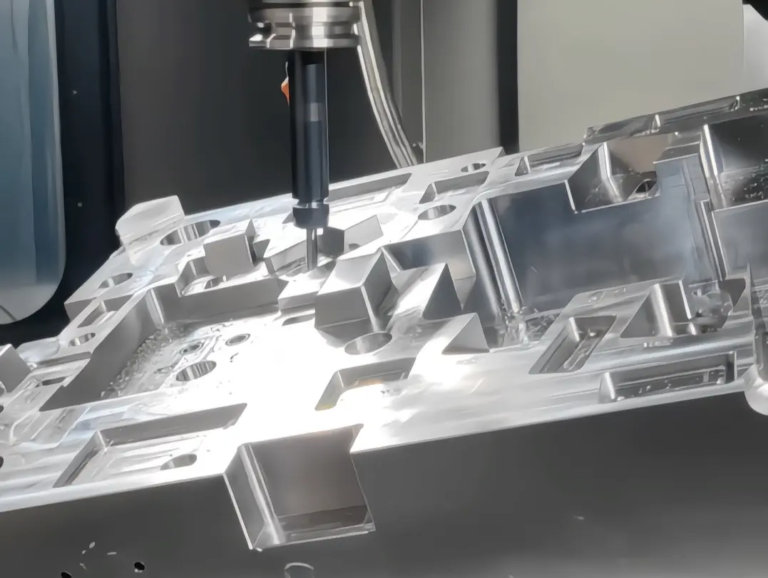

- Precision Machining: The machine executes the programmed sequence. The rotating tool removes material incrementally, following the defined paths to shape the workpiece into the target geometry. Multiple operations can be performed as the program dictates.

- Quality Control: Rigorous inspection is performed using tools like CMMs (Coordinate Measuring Machines) or optical comparators to verify tolerances, dimensions, surface finish, and geometry against the original CAD specifications.

- Post-Processing (Optional): Based on requirements, parts may receive additional treatments like deburring, heat treatment (annealing, hardening, tempering), surface coating (plating, anodizing), or final polishing.

Where Precision Turning Shines: Key Applications

The demand for precision turned parts is ubiquitous across numerous industries:

- Aerospace & Defense: Engine components (turbine blades, shafts, fittings), landing gear parts, hydraulic fittings – requiring extreme reliability and tight tolerances.

- Medical & Dental: Surgical instruments, implants, dental components (crowns, bridges) – demanding biocompatible materials and immaculate surface finishes.

- Oil & Gas: Valve bodies, pump components, fittings, seals – exposed to harsh environments and high pressures.

- Automotive: Transmission components, engine parts, suspension elements, sensors, connectors.

- Electronics: Connectors, terminal blocks, semiconductor equipment parts, precision housing components.

- Industrial Machinery: Bearings, bushings, gears, sprockets, shafts, couplings, pneumatic components.

- Energy (Renewable): Wind turbine components, hydraulic systems for power generation.

Choosing the Right Partner: Why GreatLight is Your Precision Turning Authority

While CNC Turning is a mature technology, its execution defines success. This is where a specialized partner like GreatLight becomes invaluable. As a professional five-axis CNC machining manufacturer, GreatLight leverages advanced machinery and deep expertise to tackle the most complex turning challenges.

- Five-Axis Capability: Moving beyond traditional 3-axis lathes, five-axis CNC turning allows simultaneous machining from multiple angles. This eliminates the need for multiple setups, drastically reducing cycle times, improving accuracy, and enabling the production of truly intricate, multi-faceted components like blisks (bladed disks) or complex aerospace housings with internal features.

- Comprehensive Capabilities: GreatLight doesn’t just turn. They offer one-stop post-processing and finishing services, providing a complete solution from raw material to finished, precision-engineered part. This includes deburring, heat treatment (annealing, hardening, surface hardening, case hardening, stress relieving), grinding, polishing, plating (zinc, nickel, chrome), anodizing, and more. This integration ensures consistent quality and control throughout the manufacturing chain.

- Material Expertise: They handle a vast spectrum of materials efficiently, from common steels and aluminum to demanding superalloys and exotic metals, ensuring the right material is chosen for the application and cost-effectively processed.

- Speed & Scalability: GreatLight emphasizes fast turnaround times ("quickly") for custom precision parts, crucial for meeting project deadlines. Their production infrastructure supports both rapid prototyping needs and efficient high-volume production runs.

- Quality Focus: Leveraging advanced equipment and processes, GreatLight prioritizes quality assurance, utilizing metrology equipment and stringent inspection protocols to guarantee every part meets or exceeds specifications. Their commitment to E-A-T (Expertise, Authoritativeness, Trustworthiness) is evident in their processes and customer focus.

Conclusion: Precision Engineered for Tomorrow

CNC Precision Turning is far more than just shaping metal on a lathe. It’s the foundational process enabling the creation of components that define modern technology, safety, and innovation. From the microscopic tolerances in medical implants to the robust durability of aerospace engine parts, the accuracy and consistency provided by this technology are non-negotiable. Partnering with a specialist like GreatLight, equipped with cutting-edge five-axis capabilities, comprehensive in-house finishing, and a proven commitment to quality and speed, transforms the complex challenge of custom precision part manufacturing into a reliable and efficient solution. When the performance of your components depends on unwavering precision, the expertise and integrated capabilities of a dedicated precision CNC partner are essential. Choose GreatLight for the precision that powers progress.

FAQs: CNC Precision Turning

- What’s the difference between CNC Turning and CNC Milling?

- Turning: The workpiece rotates while the cutting tool is stationary, primarily producing cylindrical shapes (shafts, hubs, pistons).

- Milling: The cutting tool rotates while the workpiece is stationary, capable of creating complex 3D shapes, cavities, slots, and features from various angles. Often used in combination with turning (turning + milling).

- What materials can CNC Turning process?

- A vast range, including Carbon Steel, Alloy Steel, Stainless Steel, Titanium, Aluminum Alloys, Brass, Bronze, Copper, Plastics (PMMA, PEEK, Nylon, etc.), and exotic/superalloys. Material choice depends on the specific application requirements.

- What tolerances can CNC Turning achieve?

- Typically ±0.0001" to ±0.0002" (±0.002mm to ±0.005mm), but capable of tighter tolerances (e.g., ±0.00005" / ±0.0001mm) depending on the material, machine, and setup. Final tolerance depends on specific part requirements.

- What surface finishes can CNC Turning produce?

- Finishes range from rough cut (Ra 3.2 – 12.5 µm) to highly polished (Ra ≤ 0.8 µm). Specific finishes (e.g., satin, brushed) can also be achieved. The finish depends on tool choice, cutting parameters, and material.

- How long does it take to get custom CNC Turning parts?

- Lead times vary significantly based on part complexity, quantity, material availability, and current order volume. GreatLight emphasizes fast turnaround times, so consulting them directly for a quote and estimated lead time is crucial.

- Can you produce custom parts based on my design?

- Absolutely. CNC Precision Turning is fundamentally a custom manufacturing process. You provide a 3D CAD model or detailed design specifications, and the manufacturer will generate the program and produce the parts to meet your exact requirements.

- Do you offer value-added services besides turning?

- Yes. Companies like GreatLight typically offer comprehensive post-processing and finishing services, including deburring, heat treatment (annealing, hardening, surface hardening, case hardening, stress relieving), grinding, polishing, plating (zinc, nickel, chrome), anodizing, and more. This allows them to act as a single source for the complete manufacturing process.

- What is the advantage of Five-Axis CNC Turning?

- Five-Axis CNC Turning enables machining from multiple angles simultaneously. This eliminates the need for multiple setups and fixtures, significantly reduces cycle times, improves dimensional accuracy, allows for the creation of more complex geometries (like internal features, undercuts, or angled surfaces), and often results in stronger, more stable parts due to better chip evacuation.

- How do you ensure part quality and precision?

- Through a combination of advanced CNC machines, rigorous programming and setup procedures, stringent quality control protocols using CMMs, optical comparators, and other inspection equipment, and a commitment to process control and continuous improvement. Reputable manufacturers have documented quality systems.

- What is the typical minimum order quantity (MOQ) for CNC Turning?

- MOQs can vary widely depending on the complexity, size, and material of the parts, as well as the manufacturer’s capabilities and setup requirements. For simple parts, it might be as low as 1-10 units, while for highly complex or large parts, it could be 50+ or even 100+. It’s essential to discuss requirements directly with the supplier.