Understanding CNC 5-Axis Machining

CNC (Computer Numerical Control) machining has revolutionized the manufacturing industry by providing precision, efficiency, and flexibility. Among the various machining processes available, 5-axis CNC machining stands out for its advanced capabilities, especially in the realm of complex parts fabrication. This article delves into the intricacies of CNC 5-axis parts machining, exploring its benefits, applications, the machining process itself, and industry trends.

What is 5-Axis CNC Machining?

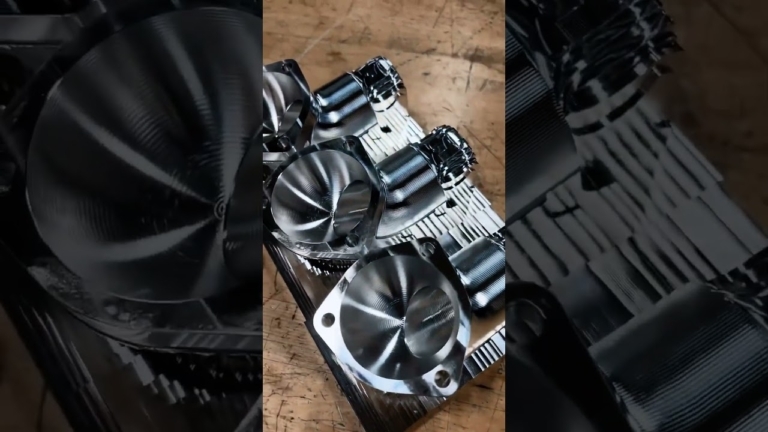

5-axis CNC machining refers to a multifaceted machining process that allows for the movement of a cutting tool or workpiece in five different axes simultaneously. In contrast to traditional 3-axis machines that move along the X, Y, and Z axes, 5-axis machines articulate about two additional rotational axes. This technology enables the production of intricate geometries and improves overall accuracy and efficiency in part fabrication.

Benefits of 5-Axis CNC Machining

There are numerous advantages to employing 5-axis CNC machining for the production of intricate parts:

1. Enhanced Precision

One of the primary reasons manufacturers opt for 5-axis machining is its unparalleled precision. The simultaneous movement of five axes minimizes the complexities of setups that often lead to errors in traditional machining practices. This precision is especially crucial in industries like aerospace, automotive, and medical devices, where tolerances can be incredibly tight.

2. Reduced Production Time

5-axis machining significantly reduces the cycle time required for complex parts. By enabling the cutting tool to approach the workpiece from multiple angles without needing to reposition it, manufacturers can achieve more operations in a single setup. This efficiency translates into reduced production time and lower operational costs.

3. Improved Surface Finish

The ability to machine from different angles allows for better tool access, which results in finer surface finishes. With a more consistent tool path and less need for repositioning, the resultant parts are often of higher quality and require less post-processing.

4. Greater Design Flexibility

5-axis CNC machining offers manufacturers the freedom to explore more complex part designs that would be difficult or impossible to produce with traditional methods. This capability allows for innovation in product development, enabling manufacturers to meet unique design specifications and adapt to changing market demands.

The 5-Axis Machining Process

The 5-axis machining process mainly involves programming, setup, and machining.

1. Programming

The initial step in the 5-axis machining process involves advanced programming, often utilizing CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. These programs generate highly detailed tool paths based on the design specifications of the part. The software is crucial in determining how the cutting tool will navigate through the material, optimizing for efficiency and accuracy.

2. Setup

Once programmed, the workpiece is set up within the CNC machine. This involves securely clamping the material to ensure stability during machining. It is essential to ensure that the workpiece is positioned correctly to achieve the desired results. Any misalignment can lead to errors, necessitating adjustments in programming or setup.

3. Machining

After programming and setup are complete, the actual machining process begins. The CNC machine executes the programmed tool paths, simultaneously moving along all five axes. As the cutting tool moves, it removes material according to the design, resulting in the final part shape. During this process, advanced sensors may be utilized to monitor performance and ensure that machining parameters remain within specified limits.

Applications of 5-Axis CNC Machining

The versatility of 5-axis CNC machining allows it to be utilized across various industries for numerous applications. Here are some notable uses:

Aerospace Industry

The aerospace sector demands incredibly precise and lightweight components. 5-axis CNC machining is ideal for manufacturing complex parts such as engine components, brackets, and housings with intricate designs that meet stringent quality standards.

Automotive Industry

In the automotive industry, manufacturers employ 5-axis machining for components like molds, dies, and engine parts. By facilitating the production of complex geometries, this technology supports the development of modern vehicles that enhance performance, efficiency, and safety.

Medical Device Manufacturing

The medical field requires exceptionally precise components, often in small quantities with complex geometries. 5-axis CNC machining excels in creating surgical instruments and implants, enabling manufacturers to produce highly customized products to meet specific medical needs.

Tool and Die Making

Manufacturers in tool and die making benefit greatly from 5-axis machining, which allows for the fabrication of complex molds and dies with superior accuracy. This capability supports the production of high-quality end products across several industries.

Trends in 5-Axis CNC Machining

As technology continues to evolve, several key trends are shaping the future of 5-axis CNC machining:

1. Automation and Robotics

The integration of robotics and automation within the CNC machining process is on the rise. Automated systems can enhance the efficiency of 5-axis machining by optimizing production schedules, reducing manual labor, and increasing operational accuracy.

2. Advanced Materials

The development of advanced materials, such as composites and titanium alloys, is pushing the boundaries of 5-axis CNC machining. Manufacturers are increasingly looking to utilize these materials for their strength-to-weight ratio, and 5-axis machining is well-equipped to handle their unique fabrication challenges.

3. Additive Manufacturing Integration

The conjunction of CNC machining with additive manufacturing (3D printing) offers a unique solution for complex parts production. This hybrid manufacturing approach allows for the creation of intricate geometries that cannot be achieved by machining alone, leading to innovative solutions in product design and development.

4. Digital Twin Technology

Digital twin technology is gaining traction in CNC machining. This technology allows manufacturers to create a virtual replica of the production process, enabling them to simulate machining scenarios, optimize production parameters, and predict potential issues before they occur.

Conclusion

CNC 5-axis parts machining is a cutting-edge technology that significantly enhances manufacturing precision, efficiency, and flexibility. With its ability to produce complex geometries, it has become an essential part of modern manufacturing across several industries. As technology continues to evolve, the integration of automation, advanced materials, and digital solutions will further streamline CNC machining processes, fostering innovation and supporting the growth of various sectors.

Incorporating 5-axis CNC machining into your manufacturing processes can propel your capabilities to new heights while meeting the demands of an ever-changing marketplace. Embracing this technology not only enhances the production of high-quality parts but also opens the door to limitless possibilities in design and engineering.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.