introduce

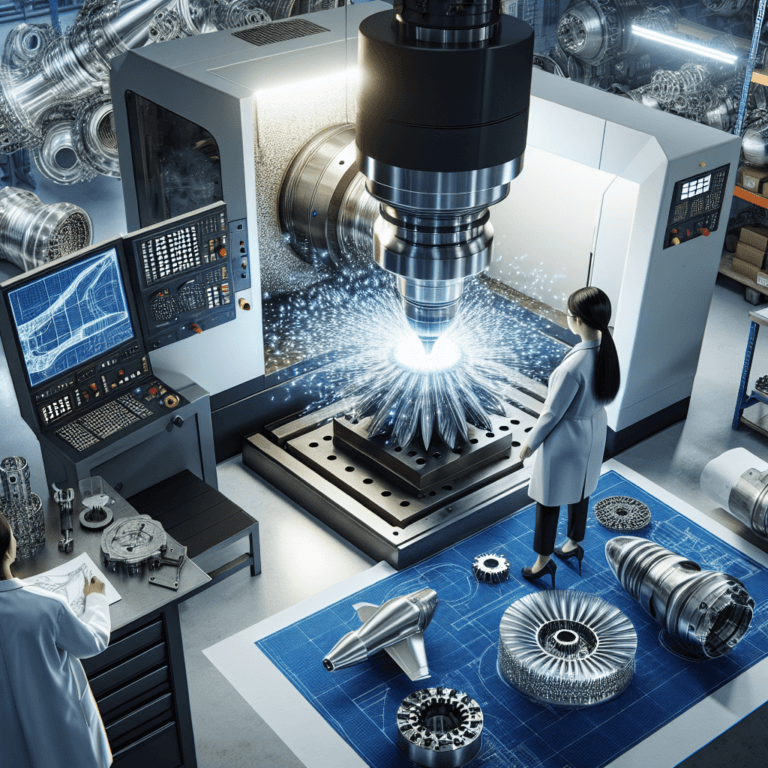

The aerospace industry continues to push technological boundaries, and at the heart of this development lie advanced machining technologies, particularly those involving computer numerical control (CNC) machining. CNC aerospace machining has revolutionized the manufacturing of critical components for aircraft and spacecraft. This blog explores the latest advances in CNC aerospace machining technology, the technologies driving these developments and the broader implications for the aerospace sector.

As we delve deeper into this topic, we’ll look at the key trends in CNC machining, including automation, precision, material advancements, and sustainability. By understanding these innovations, industry professionals can better understand how CNC machining can improve operational efficiency and product quality in aerospace manufacturing.

Learn about CNC machining in the aerospace industry

CNC machining is a computer-controlled manufacturing process that uses software to drive machine tools. It involves the precise, automated removal of material from solid blocks to create the complex geometries required for aerospace components. The process is critical in the aerospace industry because of its ability to produce complex parts with high dimensional accuracy and repeatability.

The Importance of Precision in Aerospace Machining

Aerospace parts often operate under extreme conditions, so precision machining is critical. Components such as turbine blades, landing gear and fuselage sections require tight tolerances. Any deviation from specific measurements can seriously jeopardize performance and safety. Therefore, CNC technology advancements that improve precision and quality control are crucial.

Key technologies for aerospace CNC machining

CNC machining encompasses a variety of technologies, each with unique advantages. Key technologies for aerospace processing include:

Milling: Milling operations are widely used to create complex shapes and surfaces and can be customized to produce anything from structural elements to components with complex geometries.

Turning: Involves rotating the workpiece relative to the tool to produce a cylindrical shape. This is critical for the production of engine shafts, valves and propeller components.

drilling: Critical to creating precise holes in components, drilling operations often accompany milling and turning.

Electrical Discharge Machining (EDM): EDM is suitable for complex geometries that are difficult to achieve and is especially valuable for tool and mold manufacturing.

- Laser cutting: Although primarily used for cutting operations, laser technology is increasingly used for engraving and surface modification in aerospace applications.

Each technology helps improve comprehensive CNC machining capabilities to drive innovation in aerospace manufacturing.

Latest Advances in CNC Technology

As technology has evolved, CNC machining has evolved significantly, integrating cutting-edge innovations that streamline processes, enhance quality control, and shorten cycle times.

1. Enhanced software and programming

Advanced CAD/CAM integration:

Modern CNC machine tools utilize powerful computer-aided design (CAD) and computer-aided manufacturing (CAM) software. These tools enable engineers to design complex geometries and optimize machining processes. Recent advances include improved algorithms that generate efficient tool paths, reducing time and material waste during machining operations.

Real-time monitoring and feedback system:

The integration of Internet of Things (IoT) technology in CNC machining enables manufacturers to establish real-time monitoring systems. These systems provide instant feedback on the machining process, allowing operators to make necessary adjustments at any time to minimize errors and maximize production quality.

2. Automation and Robotics

Collaborative robot (Cobot):

The adoption of collaborative robots in CNC machining environments is changing workflows. These machines increase labor efficiency by collaborating with human operators to perform a variety of tasks, including part loading/unloading, quality inspection, and even certain machining operations. As a result, manufacturers are able to increase productivity while maintaining high accuracy.

Automatic tool changer:

Automatic tool changers enable CNC machines to quickly switch between tools, reducing downtime during operation. This is critical for aerospace applications, where a single part often requires multiple machining operations.

3.Advanced processing technology

5-axis machining:

5-axis machining has become a game-changer in aerospace machining, allowing manufacturers to machine complex shapes with fewer setups. The technology allows the cutting tool to move in five axes simultaneously, helping to create complex parts in a single operation. The implementation of five-axis machining reduces cycle times and increases accuracy, making it the first choice for aerospace components.

Mixed manufacturing:

Hybrid manufacturing, which combines additive manufacturing (3D printing) with traditional machining, is becoming increasingly popular in aerospace applications. The technology creates near-net-shape parts that can then be finished using CNC machining for increased accuracy. Not only do hybrid systems reduce material waste, they also enable the production of complex geometries that would be difficult or impossible to achieve using traditional methods.

4. Material innovation

High performance alloys:

The aerospace industry increasingly relies on advanced materials such as titanium- and nickel-based superalloys, which are known for their high strength-to-weight ratios and superior performance at extreme temperatures. CNC machining technology has evolved to efficiently process these materials, using specially designed cutting tools and parameters to achieve optimal performance.

Composite materials:

The aerospace sector is experiencing a shift toward composite materials that offer enhanced performance while reducing weight. Advanced CNC technology is required to accurately machine these materials, as they often present unique challenges related to tool wear and edge performance.

5. Sustainability of CNC machining

Environmental protection practices:

Sustainability is becoming a core focus in aerospace manufacturing. Recent advances in CNC machining emphasize efficient energy use, reduced waste generation, and the use of environmentally friendly cutting fluids. As part of an overall effort to reduce its carbon footprint, the aerospace industry is turning to closed-loop cooling systems and biodegradable lubricants.

Material recycling:

The recycling of waste materials generated during CNC machining operations is receiving increasing attention to help minimize waste and promote sustainability in aerospace manufacturing. Adopting strict recycling practices is an important part of optimizing production processes and aligning with industry sustainability goals.

6. Safety and Ergonomics in CNC Machining

Enhanced security features:

Modern CNC machine tools incorporate advanced safety features such as automatic shutdown systems, emergency stop switches, and safety barriers. Ensuring operator safety is critical to maintaining a productive work environment.

Ergonomic design:

CNC workstations are increasingly designed with operator comfort and accessibility in mind. Ergonomic considerations can positively impact overall processing performance by reducing physical stress and increasing productivity.

The Impact of These Advances on Aerospace Manufacturing

1. Improve precision and quality control

The increased precision brought about by modern CNC machining technology directly translates into improved quality of aerospace components. Aerospace manufacturers benefit from reduced final product tolerances, fewer defects, and improved overall performance.

2. Shorten delivery time and reduce production costs

By employing advanced machining technologies, aerospace manufacturers can significantly reduce lead times. Technologies like 5-axis machining and hybrid manufacturing can shorten setup times and reduce cycle times per part, streamlining production processes and ultimately reducing costs.

3. Greater design flexibility

CNC machining technology allows designers to push the boundaries of creativity. The ability to accurately produce complex geometries drives innovation in aerospace design, resulting in more efficient and capable aircraft and spacecraft.

4. Enhance competitiveness

Through the integration of automation, advanced materials and sustainable practices, aerospace manufacturers can position themselves well in a highly competitive market. Employing cutting-edge CNC machining technology improves operational efficiency and confirms a commitment to quality, reliability and sustainability, which are increasingly important to customers.

Future trends in CNC aerospace machining

The trajectory of CNC aerospace machining continues to evolve. Future trends that may shape the industry include:

Artificial Intelligence and Machine Learning: Integrating artificial intelligence and machine learning algorithms into CNC operations can take real-time monitoring and predictive maintenance to the next level, improving operational efficiency.

Digital twin: As the industry moves towards Industry 4.0, the use of digital twins (virtual replicas of physical assets) will provide insights into performance and facilitate more informed decisions during production processes.

Advanced materials research: Continued research into developing new materials, such as lighter, stronger alloys, will require CNC machine tools to adapt and evolve to efficiently process these materials.

- Integration of blockchain technology: Ensuring traceability and compliance in aerospace manufacturing may benefit from blockchain technology, increasing transparency and accountability in CNC machining processes.

in conclusion

Advances in CNC aerospace machining technology mark a critical point in the development of manufacturing in the aerospace industry. By leveraging innovative technologies, manufacturers can optimize precision, increase productivity and significantly reduce costs while adhering to sustainability goals. As we move towards a future shaped by automation, advanced materials and smart manufacturing processes, CNC machining will continue to play a vital role in meeting the needs of the aerospace sector.

FAQ section

1. What is CNC machining?

CNC machining is a manufacturing process controlled by computer software that automatically removes material from a workpiece to create a part. Due to its accuracy and efficiency, it is widely used in various industries including aerospace.

2. Why is accuracy important in aerospace machining?

Precision is critical in aerospace machining because aircraft and spacecraft operate under extreme conditions and even small deviations in part dimensions can compromise safety and performance.

3. How does advanced CNC machining technology improve production efficiency?

Advanced technologies such as automation and real-time monitoring streamline processes by reducing cycle times, optimizing tool paths and minimizing handling. This ultimately increases productivity and reduces production costs.

4. What are the benefits of using 5-axis machining?

5-axis machining allows the cutting tool to move in multiple axes simultaneously, enabling complex geometries to be produced in a single setup. This significantly reduces manufacturing time and increases accuracy.

5. How does CNC aerospace machining address sustainability issues?

Sustainability is enhanced through the implementation of environmentally friendly practices such as the use of biodegradable lubricants, energy-saving machinery, and recycling of waste materials generated during machining processes.

This extensive exploration of advances in CNC aerospace machining not only highlights key technologies transforming the industry, but also emphasizes the importance of continued innovation in achieving excellence in aerospace manufacturing.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.