Introduction to CNC machining

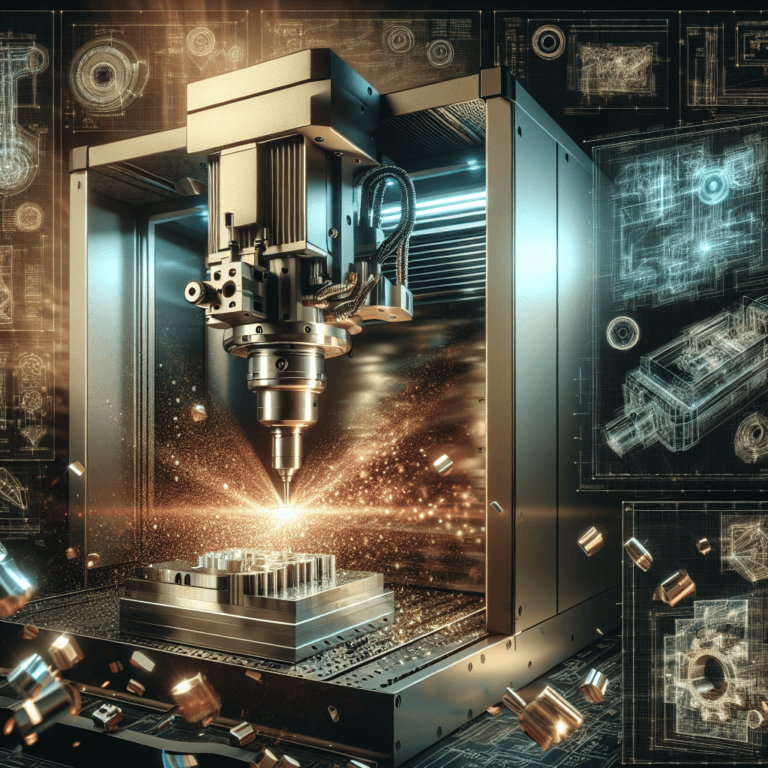

In modern manufacturing, computer numerical control (CNC) machining has become a key technology, revolutionizing the way we approach precision engineering. From the aerospace to the automotive industry, CNC machining plays a key role in producing complex parts with high precision and efficiency. This blog post takes an in-depth look at the latest innovations in CNC machining technology, highlights their impact on the production process, and discusses the future of this fundamental technology.

The evolution of CNC machining

historical background

The origins of CNC machining can be traced back to the early 1940s, when the first CNC machine tools were developed. Initially, due to the complexity and cost of these machines, they were mainly used in professional industries. As computer technology advanced in the 1960s and 1970s, CNC systems became easier to use, resulting in increasing adoption in various fields.

Transition to digital systems

The transition from analog to digital systems marks an important turning point in CNC machining. In this digital age, the integration of complex software allows greater flexibility in programming and design. This evolution paves the way for advanced CNC machining technologies that increase precision, efficiency and scalability.

Key Innovations in CNC Machining

1. Multi-axis machining

Overview

Multi-axis CNC machining involves using multiple axes (usually 4 to 6) to create complex geometries that are difficult to achieve using traditional 3-axis machine tools. The technology is particularly beneficial for manufacturing complex components used in industries such as aerospace, medical devices and automotive.

benefit

- Improve accuracy: Multi-axis machining can create complex shapes with higher precision, reducing the need for secondary operations.

- Reduce setup time: Combines multiple machining processes into a single operation, minimizing time spent on tool changes and setup.

- Improve tool life: Ability to optimally position tools, reducing wear and extending tool life.

2. Additive manufacturing integration

Overview

The integration of additive manufacturing (AM) and CNC machining represents a paradigm shift in production processes. This hybrid approach leverages the strengths of both technologies, allowing manufacturers to create complex parts with complex internal geometries.

Main features

- Material diversity: The combination of subtractive and additive processes allows the use of a variety of materials, including metals and polymers.

- Design freedom: Designers can create components that were previously impossible, enabling innovation in product design and functionality.

- Cost effective: Hybrid systems can provide significant cost savings by reducing material waste and production time.

3. Automation and Robotics

Overview

Automation in CNC machining refers to the combination of robotic systems and intelligent software to streamline the production process. From automated loading and unloading systems to process quality control, automation plays a vital role in improving efficiency.

advantage

- Increase throughput: Automated systems can operate continuously, significantly increasing productivity.

- consistent quality: Robots can maintain high levels of accuracy and repeatability, reducing the risk of human error.

- Adaptability: With advanced software algorithms, automated CNC systems can quickly adapt to changing production needs.

4. Internet of Things (IoT) Integration

Overview

IoT integration in CNC machining involves connecting machines and sensors to a centralized network for real-time monitoring and data analysis. This innovation enhances decision-making and predictive maintenance capabilities.

benefit

- Predictive maintenance: IoT sensors can reduce downtime by monitoring machine conditions and alerting operators before potential problems escalate.

- Data-driven insights: Collecting data from machinery enables manufacturers to analyze performance metrics and optimize production processes.

- remote monitoring: Operators can monitor machines remotely, improving operational flexibility and response time.

5.Advanced mold technology

Overview

Innovative tool technology plays an important role in enhancing CNC machining capabilities. Developments in tool materials, coatings and designs are pushing the boundaries of what is possible.

feature

- High performance materials: Cutting tools made from advanced materials such as carbide and ceramics improve durability and efficiency.

- coating: The application of special coatings reduces friction, improves wear resistance, and extends tool life.

- Custom tooling solutions: Custom tooling solutions can be developed for specific applications, optimizing performance for unique machining tasks.

Application of advanced CNC machining technology

aerospace industry

In the aerospace industry, precision and reliability are critical. Advanced CNC machining technology enables manufacturers to produce lightweight, complex parts that comply with strict regulations. The use of multi-axis machining and hybrid additive processes is particularly beneficial for the production of complex parts such as turbine blades and aircraft frames.

Automotive field

The automotive industry continues to seek innovative solutions to meet consumer demands for efficiency and performance. Advanced CNC machining technology, including automation and IoT integration, improves production of critical components such as engine blocks, transmissions and custom accessories, resulting in shorter lead times and improved quality.

medical device

The medical device industry requires precision and safety in the manufacturing process. CNC machining innovations can create complex implants and surgical instruments that meet high precision standards. Multi-axis machining and advanced tooling play a vital role in producing complex geometries that meet individual patient needs.

Robotics and Automation

As automation and robotics become increasingly integrated into manufacturing, advanced CNC machining technology lays the foundation for manufacturing complex robotic parts. The flexibility and precision achieved through multi-axis machining are critical to producing the complex components required for modern automation systems.

The future of CNC machining

Sustainability focus

With growing concerns about environmental impact, the future of CNC machining is likely to emphasize sustainability. Innovations such as the use of environmentally friendly materials, energy-saving machines and waste-reducing technologies will be a central theme in the industry. The combination of advanced CNC machining and sustainable practices will help manufacturers reduce their carbon footprint.

Increase customization

Customization will continue to be a key driver of the future of CNC machining. As consumer demands shift toward personalized solutions, advanced processing technologies will enable manufacturers to efficiently meet these demands. The rise of digital twin technology will further enhance the ability to create customized components through simulation and predictive modeling.

Artificial Intelligence (AI) Integration

Integrating artificial intelligence into CNC machining is set to revolutionize the industry. Automatic learning algorithms analyze production data to make real-time adjustments, optimize tool paths and predict machine failures. The synergy between artificial intelligence and advanced CNC technology will increase efficiency and reduce operating costs.

global competitiveness

As advanced CNC machining technologies continue to evolve, companies that adopt these innovations will gain a competitive advantage in the global market. The ability to produce high-quality components quickly and cost-effectively is critical for manufacturers who want to succeed in an increasingly demanding environment.

in conclusion

Innovations in advanced CNC machining technology are changing the manufacturing landscape, driving efficiency, precision and customization across industries. Through the integration of multi-axis machining, additive manufacturing, automation, IoT and advanced tooling, manufacturers can meet the challenges of today’s market while preparing for the future. As sustainability, customization and artificial intelligence continue to shape the industry, CNC machining will continue to be at the forefront of manufacturing technology, enabling businesses to thrive in an ever-changing environment.

FAQ section

Q1: What is CNC machining?

CNC machining is a manufacturing process that uses computer-controlled machines to create precision parts and components from a variety of materials. It uses CNC to automatically move the tool, allowing for high precision and repeatability.

Q2: What are the benefits of multi-axis machining?

Multi-axis machining creates complex geometries in a single operation, improving accuracy, reducing setup time and extending tool life. This minimizes the need for secondary machining and provides greater design flexibility.

Q3: How does the Internet of Things improve CNC machining?

IoT integration in CNC machining enables real-time monitoring and predictive maintenance of machines. Sensors collect data that can be analyzed to optimize performance, reduce downtime and enhance decision-making processes.

Q4: What role does automation play in CNC machining?

Automation of CNC machining involves the use of robots and smart software to streamline the production process. Automated systems increase throughput, maintain consistent quality, and adapt to production needs, resulting in significant efficiencies.

Q5: How does CNC machining contribute to sustainable development?

Innovations in CNC machining can promote sustainability by reducing material waste, using energy-saving technologies and incorporating environmentally friendly materials. These practices help manufacturers minimize their impact on the environment while maintaining high-quality production.

This blog post comprehensively explores innovations in advanced CNC machining technology, structured with appropriate H tags. Content can be further expanded with more specialized sections or examples based on specific industry applications, current market trends, or case studies, while maintaining a keyword density of 1-2% as needed.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.