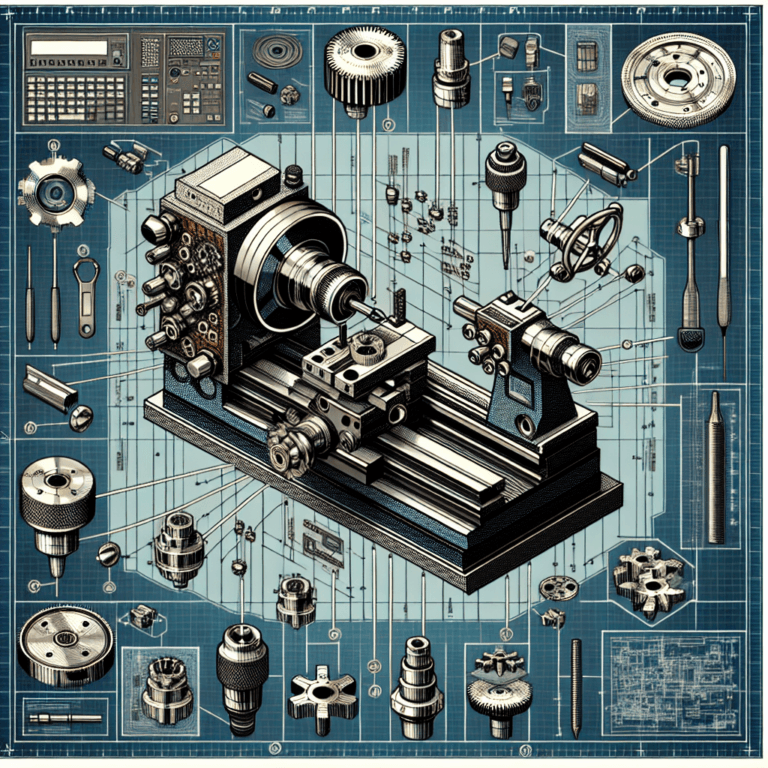

Understanding the Functions and Features of CNC Precision Vertical Lathes

CNC precision vertical lathes are among the most critical tools used in modern manufacturing, particularly in sectors that require high precision and efficiency. They are designed to perform various machining tasks, including turning, threading, and facing operations with exceptional accuracy. In this article, we will delve into the functions and features of each component of a CNC precision vertical lathe to provide you with a comprehensive understanding of how they work and their applications in manufacturing.

Components of CNC Precision Vertical Lathes

1. Bed

The bed is the foundational component of a CNC vertical lathe. It provides stability and support for all other parts, ensuring that vibrations and movements are minimized during operation. The bed is typically made from high-strength cast iron or other robust materials to withstand the intense forces exerted during machining. A well-constructed bed contributes to the overall precision of the machine, which is crucial for producing high-quality components.

2. Column

The column is mounted on the bed and houses essential components such as the spindle, drive motors, and control systems. It plays a pivotal role in maintaining the alignment of the machine’s axes. The column’s rigidity is crucial for achieving accurate machining results, especially when dealing with heavy workpieces. Some advanced vertical lathes come with a dual-column design that enhances stability and allows for higher load capacities.

3. Spindle

The spindle is one of the most vital components of a CNC vertical lathe, as it holds and rotates the workpiece during machining. It is typically mounted vertically in this type of lathe, allowing gravity to assist in the machining process. The spindle’s speed can be adjusted to accommodate various materials and cutting processes, with many modern lathes featuring high-speed spindle options that enhance productivity. Precision bearings support the spindle, ensuring minimal runout and maintaining accuracy throughout the machining cycle.

4. Tool Holder

The tool holder is an interchangeable component that secures the cutting tools in place. There are several types of tool holders available, including live tools, static tools, and quick-change systems. The choice of tool holder affects the lathe’s versatility and can determine the range of operations that can be performed. A CNC vertical lathe with an advanced tool holder system allows for rapid tool changes, reducing downtime and increasing machining efficiency.

5. Cross Slide

The cross slide is responsible for allowing the cutting tool to move horizontally and vertically across the workpiece. This component can be adjusted to different heights and angles to achieve various machining operations, such as taper turning or contouring. The cross slide’s movement is precision-controlled through the CNC system, ensuring that every pass of the cutting tool is exact, which results in superior finishes and tolerances.

6. Ram

In some CNC vertical lathes, especially those designed for larger workpieces, a ram is employed to provide additional movement capabilities. The ram can extend and retract to facilitate various cutting depths and angles. It allows the machine to reach areas that may be difficult for standard cross slides, making it valuable for complex parts and tight spaces.

7. CNC Control System

The CNC control system is the brain of the vertical lathe. It interprets the programmed instructions and translates them into commands for the machine’s movements and operations. Modern CNC controls come equipped with intuitive user interfaces that allow operators to easily input designs and machining parameters. Many systems offer advanced features such as real-time monitoring, error reporting, and the ability to simulate machining processes before actual execution, thus preventing potential mistakes.

8. Coolant System

A proper coolant system is essential for high-performance machining. It prevents overheating of both the tool and the workpiece, which can degrade material properties and lead to premature tool wear. CNC vertical lathes often include comprehensive coolant management systems that can mist, flood, or provide through-tool cooling depending on the machining requirements. Proper cooling helps maintain dimensional accuracy and extends the lifespan of cutting tools.

9. Chip Removal System

During machining, metal chips and debris are produced. A chip removal system is vital for maintaining a clean work area and ensuring consistent machining quality. Many CNC vertical lathes are equipped with automatic chip removers or conveyors that transport waste materials away from the work area, reducing the need for manual clean-up and minimizing downtime.

10. Safety Features

Safety is a paramount concern in any manufacturing environment. CNC precision vertical lathes are fitted with various safety features to protect operators and equipment. These may include emergency stop buttons, safety interlocks, protective covers, and alarms alerting users to potential issues. In addition, many modern lathes are equipped with sensors to monitor operating conditions and prevent accidents.

Applications of CNC Precision Vertical Lathes

CNC precision vertical lathes are used in various industries, including aerospace, automotive, and medical device manufacturing. They are particularly effective in producing components with complex shapes and demanding tolerances. Common applications include:

- Machining of gears and pulleys

- Production of flanges and fittings

- Fabrication of housings and enclosures

- Precision components for engines and turbines

Advantages of CNC Precision Vertical Lathes

The use of CNC precision vertical lathes offers numerous advantages over traditional machining methods:

Increased Precision: CNC technology allows for tighter tolerances and repeatability in production runs, crucial for quality control.

Enhanced Automation: CNC lathes can operate autonomously with minimal human intervention, leading to higher productivity levels.

Flexibility: These lathes can easily adapt to different machining tasks and materials, making them versatile solutions for various production needs.

Reduced Cycle Times: Faster processing speeds and efficiency improvements lead to reduced machine cycle times, which is critical in high-volume manufacturing.

- Improved Surface Finish: The precision control of CNC lathes often results in better surface finishes compared to manual machining.

Conclusion

CNC precision vertical lathes stand as a testament to the advancements in manufacturing technology. Each component, from the robust bed and column to the intelligent CNC control systems, plays a significant role in ensuring that these lathes deliver high-quality machining results. As industries continue to demand greater precision and efficiency, understanding the functions and features of these machines becomes increasingly important. Whether for intricate components in aerospace or high-volume parts in automotive manufacturing, CNC vertical lathes are invaluable assets that drive technological progress and promote operational excellence. As we move forward, ongoing innovations in CNC technology will likely enhance their capabilities even further, making them an integral part of future manufacturing processes.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.