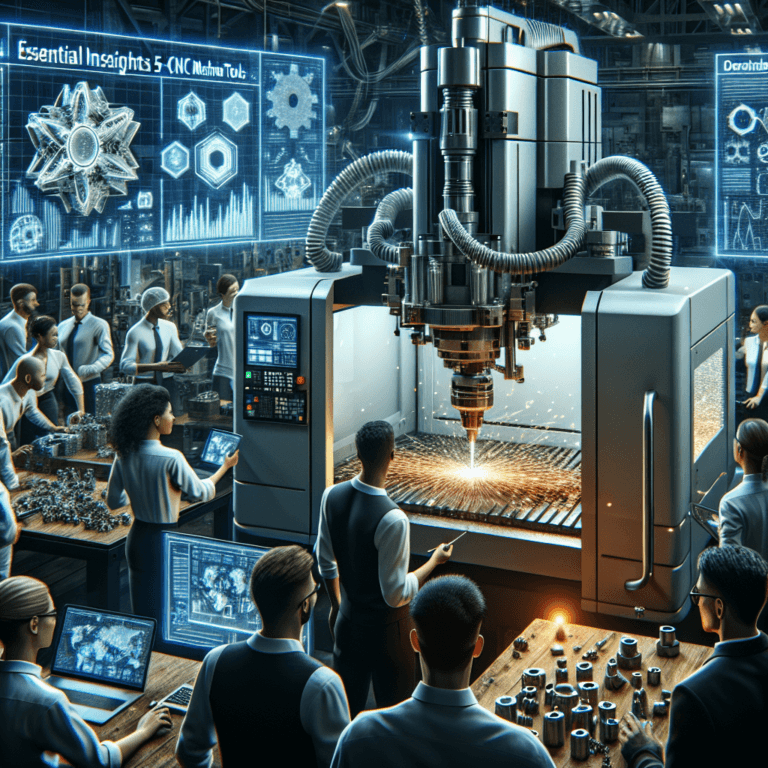

Understanding 5-Axis CNC Machine Tools

5-axis CNC (Computer Numerical Control) machine tools have become increasingly important in the manufacturing industry due to their ability to produce complex parts with incredible precision. These machines operate on five different axes of motion, allowing for greater flexibility, reduced production time, and superior surface finishes compared to traditional 3-axis machining systems. Below, we will explore the key points of knowledge about 5-axis CNC machine tools, including their benefits, modes of operation, applications, and considerations for use.

What is a 5-Axis CNC Machine?

A 5-axis CNC machine tool is designed to move a cutting tool or workpiece along five different axes simultaneously. The first three axes (X, Y, and Z) correspond to the standard Cartesian coordinates, representing lateral movement, forward/backward, and up/down motion, respectively. The additional two axes allow for rotation around the X and Y axes, significantly enhancing the machine’s versatility.

Key Benefits of 5-Axis CNC Machining

Increased Precision and Accuracy

The primary advantage of 5-axis CNC machining is the ability to create intricate and complex shapes with precise tolerances. The simultaneous movement across multiple axes means that components can often be machined in one setup, reducing the risk of misalignment and errors.Reduced Production Time

With traditional 3-axis machining, parts may require multiple setups and repositioning, which can be time-consuming. In contrast, 5-axis CNC machines can perform multiple operations in a single setup, minimizing cycle times and boosting overall efficiency.Enhanced Tool Life

By enabling the cutting tool to approach the workpiece from various angles, 5-axis machining can reduce tool wear. This leads to longer tool life and less frequent replacements, ultimately saving costs.Complex Geometry Capability

5-axis CNC machines excel at producing intricate geometries that would be impossible or overly complicated to create using 3-axis machines. This includes components with undercuts, compound angles, and intricate details, making them essential in industries like aerospace, automotive, and medical device manufacturing.- Improved Surface Finish

The advanced technological capabilities of 5-axis CNC machining typically result in improved surface finishes. The ability to control the angle and position of the tool closely leads to smoother cuts and less post-processing, enhancing the final product’s quality.

Types of 5-Axis CNC Machines

There are several types of 5-axis CNC machines, each designed to cater to specific manufacturing needs:

Continuous 5-Axis Machining

This type of machine allows for continuous movement along all five axes, providing unmatched precision. This is often employed for high-precision industries such as aerospace and medical device manufacturing.Indexed 5-Axis Machining

In indexed 5-axis machining, the workpiece is positioned and locked in place before milling operations are conducted. This method is commonly used for applications where the geometry is less complex and can be efficiently managed in distinct setups.- Hybrid 5-Axis Machining

Some machines combine additive and subtractive manufacturing capabilities, allowing for the production of complex parts that require both machining and 3D printing techniques.

Applications of 5-Axis CNC Machining

The applications for 5-axis CNC machining are vast and varied, owing to its versatility and precision. Some of the most common industries include:

Aerospace

This industry often requires components with intricate designs and high tolerances. 5-axis CNC machining is crucial for producing complex parts like turbine blades and airframe structures efficiently.Automotive

In automotive manufacturing, 5-axis systems are utilized for producing high-precision components such as engine parts, transmission cases, and molds.Medical Devices

The medical field demands precision and compliance with strict regulatory standards. 5-axis CNC machines are commonly used to create components such as implants, surgical instruments, and custom prosthetics.Molds and Die

Creating die molds requires intricate designs and high precision, making 5-axis machining ideal for producing high-quality molds in less time.- Consumer Products

The rapidly evolving consumer products sector benefits from 5-axis CNC machining, allowing for the rapid prototyping and production of complex designs.

Considerations for Using 5-Axis CNC Machines

While 5-axis CNC machines offer numerous benefits, there are essential considerations to keep in mind before implementing them:

Initial Cost

The investment in a 5-axis CNC machine can be significantly higher than that of traditional 3-axis machines. Businesses need to evaluate whether the potential return on investment justifies this cost.Skill Requirements

Operating a 5-axis CNC machine requires advanced programming and operational skills. Companies may need to invest in training for their operators to maximize the machine’s capabilities.Software Complexity

The software used for 5-axis CNC machining can be more complicated compared to traditional systems. Ensuring access to appropriate software tools and training for staff is vital for successful operation.Workholding Solutions

Effective workholding is critical to achieving the required precision levels in 5-axis machining. Businesses must explore various clamping solutions to secure and stabilize parts during machining.- Maintenance Needs

With increased capabilities comes the need for diligent maintenance. Regular servicing of components and careful monitoring of tool wear are crucial to maintain performance and precision.

Conclusion

5-axis CNC machine tools represent a significant advancement in the field of manufacturing, offering enhanced precision, efficiency, and the ability to create complex geometries. Their applications span various industries, making them indispensable in modern production settings. While the investment, skill requirements, and maintenance needs may pose challenges, the long-term benefits of adopting 5-axis machining technology are well worth the consideration for any business looking to enhance their manufacturing process. By understanding the key points of knowledge surrounding 5-axis CNC machines, companies can leverage this powerful technology to their advantage and stay competitive in an ever-evolving market.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.