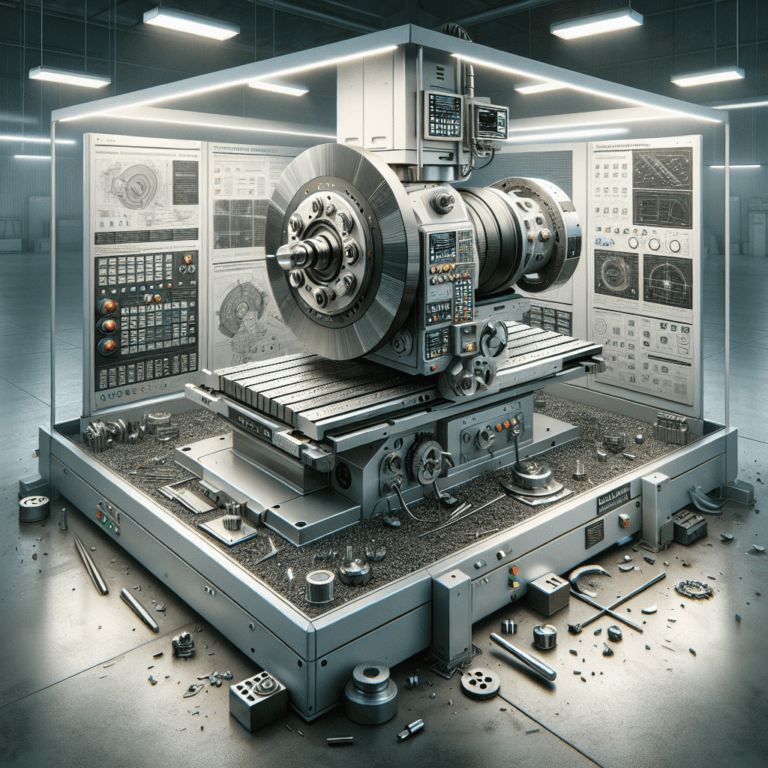

In the fast-paced world of modern manufacturing, precision and efficiency are paramount. As industries strive to create top-quality products with minimal waste and increased productivity, the demand for advanced machining equipment has soared. One such machine that has garnered attention for its remarkable capacity to meet these criteria is the high-precision CNC horizontal axis rotary table surface grinder. This innovative equipment is not only essential for achieving optimal surface finishes but also plays a key role in enhancing overall operational effectiveness.

## Understanding the CNC Horizontal Axis Rotary Table Surface Grinder

### What is a CNC Surface Grinder?

A CNC (Computer Numerical Control) surface grinder is a highly specialized machining tool used to produce flat, angular, and contoured surfaces. This machine relies on programmable controls to automate the grinding process, delivering a high level of precision and repeatability. The horizontal axis design of the rotary table allows for improved stability and control during the grinding process, making it suitable for a wide variety of materials, including metals, plastics, and composites.

### The Role of the Rotary Table

The rotary table is a standout feature of this surface grinder. It provides a circular work surface that allows the workpiece to rotate smoothly under the grinding wheel. This capability significantly enhances productivity by enabling the operator to grind multiple faces of a workpiece without needing to reposition it manually. Furthermore, the rotary table enhances precision since the grind can be performed seamlessly across all dimensions of the part.

## Advantages of High-Precision CNC Horizontal Axis Rotary Table Surface Grinders

### Enhanced Precision and Accuracy

One of the defining features of high-precision CNC horizontal axis rotary table surface grinders is their ability to achieve extraordinary levels of accuracy. These machines are equipped with advanced measuring systems and feedback loops that help ensure that the grinding operations are executed with minimal deviation from the desired specifications. This precision is particularly crucial for industries such as aerospace, automotive, and medical device manufacturing, where even the slightest error can result in catastrophic failures.

### Increased Productivity

Productivity in any manufacturing environment is a primary concern. The use of a CNC rotary table not only speeds up the grinding process but also allows for simultaneous grinding of multiple surfaces. This capability significantly reduces cycle times, allowing manufacturers to meet tight deadlines while maintaining the high-quality output required by today’s competitive markets. Moreover, the automation inherent in CNC technology minimizes the need for manual intervention, further boosting productivity.

### Versatility in Applications

High-precision CNC horizontal axis rotary table surface grinders are incredibly versatile. They can be employed for grinding a vast range of materials and components, from complex geometries to simple flat surfaces. This flexibility makes them suitable for various industries, including tooling, mold-making, and the production of precision components. Additionally, these machines are capable of integrating with other manufacturing processes, enabling a seamless workflow.

### Reduced Material Waste

Efficient grinding processes result in less material waste. By employing CNC technology, manufacturers can achieve precise tolerances and finishes, making it easier to utilize raw materials effectively. This reduction in waste not only lowers production costs but also aligns with sustainable manufacturing practices, which are becoming increasingly important in the industry.

## Key Features to Look for in High-Precision CNC Horizontal Axis Rotary Table Surface Grinders

### Robust Construction and Design

When selecting a CNC surface grinder, it’s crucial to consider the machine’s construction and design. A robust build typically indicates greater stability during grinding operations, which contributes directly to the precision of the final product. Look for machines made from high-quality cast iron or other durable materials that can withstand continuous heavy usage.

### Advanced Control Systems

The control system is the brain of any CNC machine, and high-precision surface grinders should come equipped with advanced CNC software. Features like intuitive user interfaces, real-time monitoring, and integrated diagnostics aid operators in achieving optimal performance. Some modern machines even include smart technology that allows for remote monitoring and predictive maintenance, further enhancing operational efficiency.

### Customization Options

Manufacturers often need specific configurations tailored to their production needs. High-precision CNC horizontal axis rotary table surface grinders that offer customizable options allow businesses to adapt the machine’s capabilities to a wide range of parts and configurations. Features such as different spindle speeds, wheel sizes, and options for various grinding heads make these machines incredibly versatile.

### Safety Features

Safety is paramount in any manufacturing setup. High-precision CNC grinders should come equipped with safety features like emergency stops, guarding systems, and automatic shutoff functions. Additionally, machines that minimize exposure to harmful dust and noise can greatly enhance the working environment for operators.

## Maintenance and Best Practices for Maximizing Performance

To ensure that a high-precision CNC horizontal axis rotary table surface grinder delivers optimal performance, regular maintenance is key. Here are some essential maintenance practices:

### Schedule Routine Inspections

Regularly inspecting the machine for wear and tear can help catch potential issues before they escalate. Pay attention to grinding wheels, bearings, and other critical components that may need replacement over time.

### Keep the Work Area Clean

A clean work environment is crucial not only for safety but also for machine performance. Regularly removing metal shavings, dust, and coolant residues ensures that the machine operates without hindrance and maintains optimal performance levels.

### Calibrate Regularly

Routine calibration of the CNC system and the rotary table guarantees that the machine produces consistently precise results. This task often requires specialized skills, so it’s advisable to engage professionals if necessary.

### Invest in Training

Proper training for operators and maintenance personnel is vital. Understanding the machine’s functions and capabilities enhances not only safety but also the efficiency of the grinding process.

## Future Trends in CNC Surface Grinding Technology

As technology advances, the capabilities of CNC surface grinders are set to evolve even further. Emerging trends include:

### Integration of Artificial Intelligence

Artificial intelligence (AI) has the potential to revolutionize CNC surface grinding by enhancing process automation. AI systems can analyze operational data, predict maintenance needs, and optimize grinding parameters in real-time for increased efficiencies.

### Improved Material Technology

The development of new grinding wheel materials that are more durable and effective will likely enhance the performance of CNC surface grinders. Innovations in material technology aim to reduce wear and improve the grinding process, leading to even finer finishes.

### Smart Manufacturing Environments

With the rise of the Industrial Internet of Things (IIoT), the future of CNC surface grinding will likely see greater connectivity between machines, operators, and production systems. This transformation will facilitate data sharing and real-time decision-making, driving even higher levels of efficiency and productivity.

## Conclusion

In conclusion, the high-precision CNC horizontal axis rotary table surface grinder is an essential tool for modern manufacturing. With its advanced capabilities in precision, productivity, and versatility, it meets the rigorous demands of contemporary industry. As manufacturers continue to seek out ways to optimize processes and enhance product quality, investing in this type of equipment is not only wise but necessary for staying competitive in today’s market. As technology continues to advance, the future of CNC grinding looks even brighter, paving the way for innovations that will shape the manufacturing landscape for years to come.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.